- Joined

- Nov 1, 2016

- Messages

- 24

- Reaction score

- 16

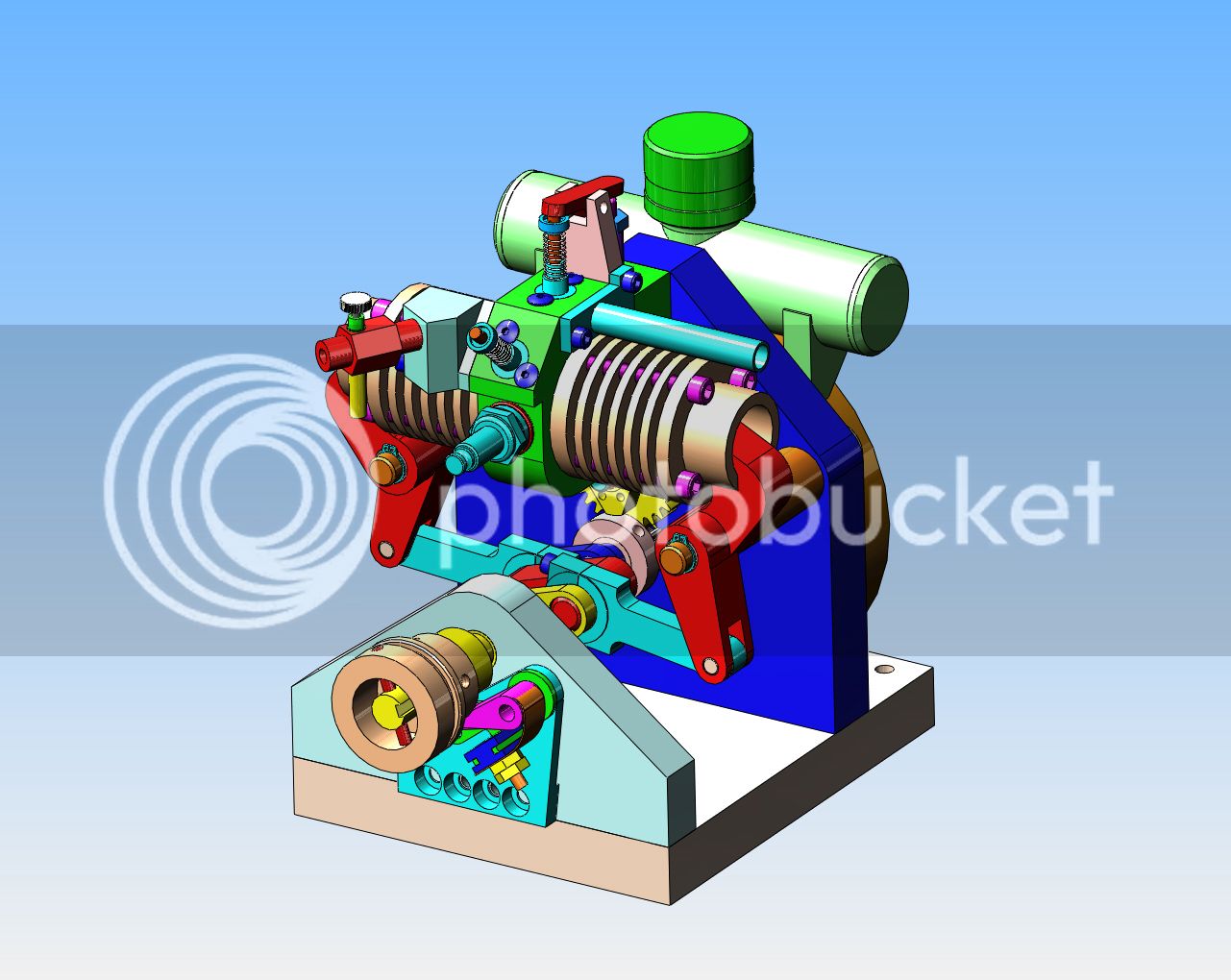

I would appreciate any help you guys can give me troubleshooting my Webster IC engine. I have been at it for a while and am growing frustrated.

This is my first IC engine build. Before starting, I read all the posts on HMEM, studied everyone's Webster build logs, watched all the runners on YouTube then got the courage to get going. I finished the engine 2 weeks ago and have been trying to get it to go ever since.

No matter what I do, I cannot get the thing to fire. I am convinced there is something fundamentally wrong.

What I have:

Thanks, Bill

This is my first IC engine build. Before starting, I read all the posts on HMEM, studied everyone's Webster build logs, watched all the runners on YouTube then got the courage to get going. I finished the engine 2 weeks ago and have been trying to get it to go ever since.

No matter what I do, I cannot get the thing to fire. I am convinced there is something fundamentally wrong.

What I have:

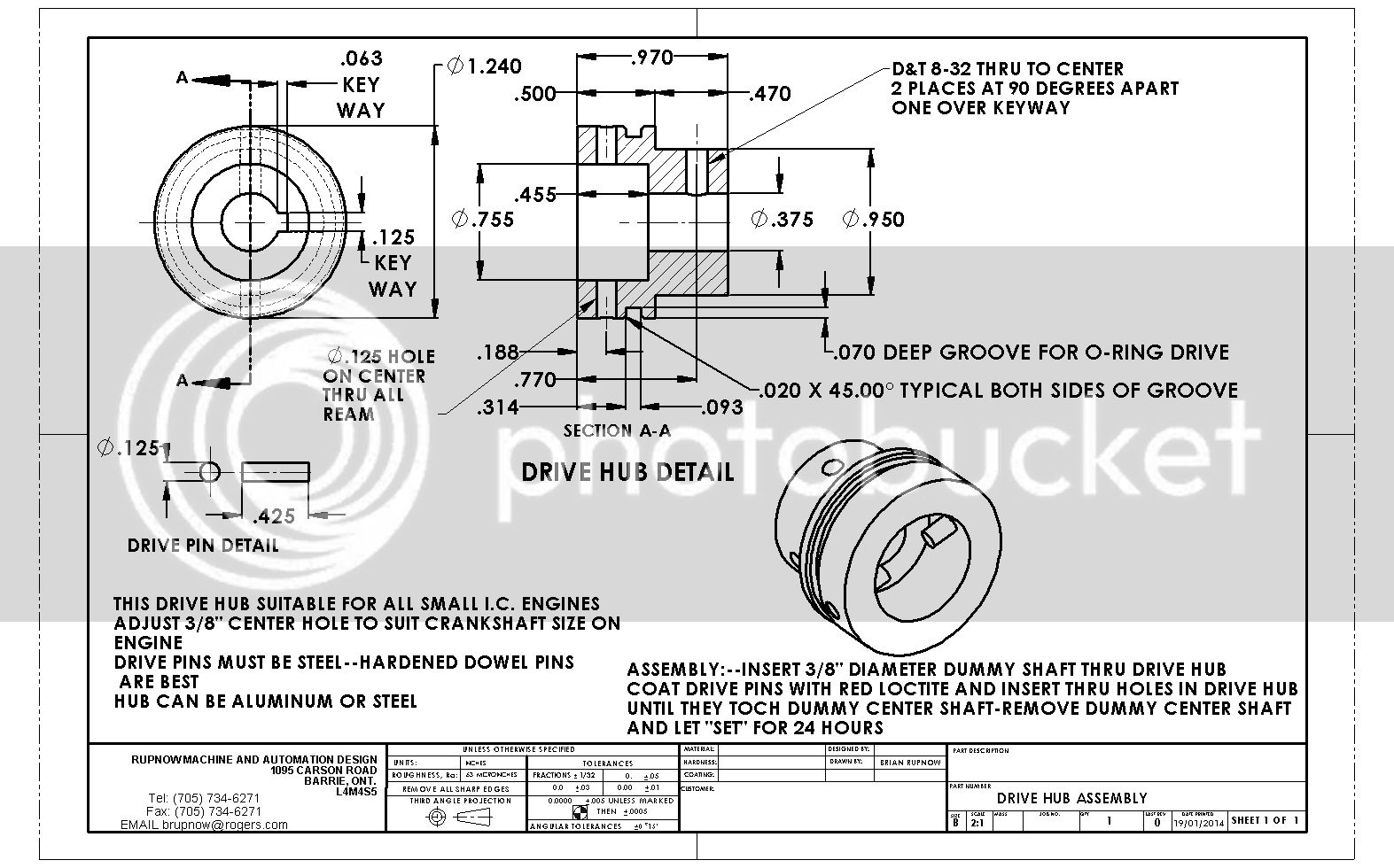

- The engine was built exactly to the plans, except: 1) I used a Viton o-ring with grooves sized per Brian's build instead of cast rings, 2) I used 0.006" paper gaskets on the fuel block where none were specified, and 3) I used 1/64" paper/fiber gasket material for a head gasket

- The peripheries are also per plan - points, condenser, coil, and car battery

- Carburetor is Traxxas Pro-0.15, at factory settings

- Fuel is Coleman Camp Fuel

- The ignition timing is set to have the points begin to open at TDC and are gapped at 0.020"

- The exhaust timing is set such that the exhaust valve begins to open at 15 deg BDC

- Draws fuel through the fuel line when I turn the flywheel and block the carb inlet on the intake stroke, and rejects fuel on the exhaust stroke

- Draws fuel into the combustion chamber

- Generates a spark at the points and also at the spark plug when points open and again when they first close

- Has compression, but I am not sure if it is acceptable. 1) When I rotate the flywheel with the drill, the intake valve moves, but not a lot, and 2) when I wet the head gasket with fuel and move the piston on the compression stroke, I see small bubbles escaping uniformly around the head gasket

- Tried a 0.015" copper head gasket and a 0.006" paper gasket. About the same compression. Torqued the head bolts as tight as I can get them

- Resurfaced the cylinder "block" and the head trying for a better fit. Bubble escape rate is about the same

- Tried a fresh o-ring

- Re-lapped the valves to their seats, then tested the seal by removing the valve block and blowing through the exhaust pipe and through the intake port. No leaks

- Shot starting fluid into the carb, while holding the intake valve open. Still no firing when cranking the flywheel

- Double checked wiring, switched out the points and coil, and measured the battery voltage at 14.8v

- Tried advanced and retarded ignition timing

Thanks, Bill