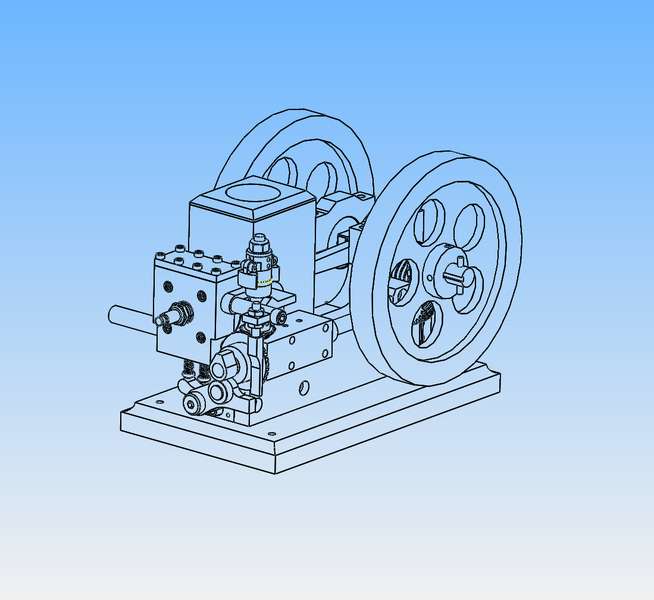

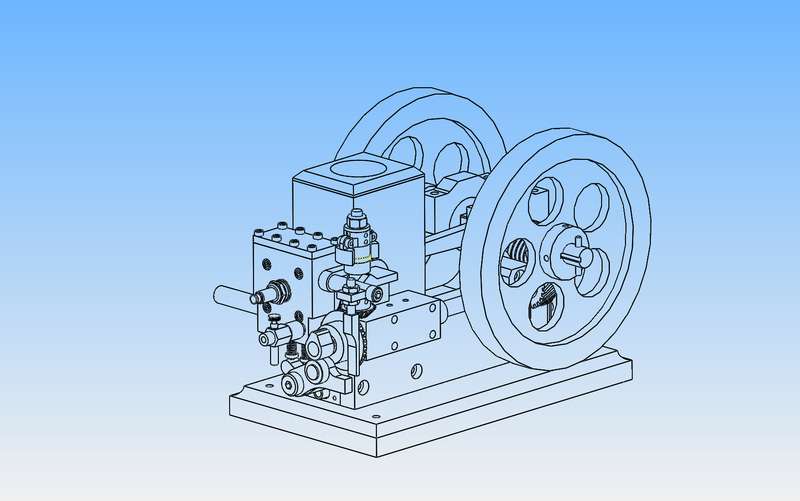

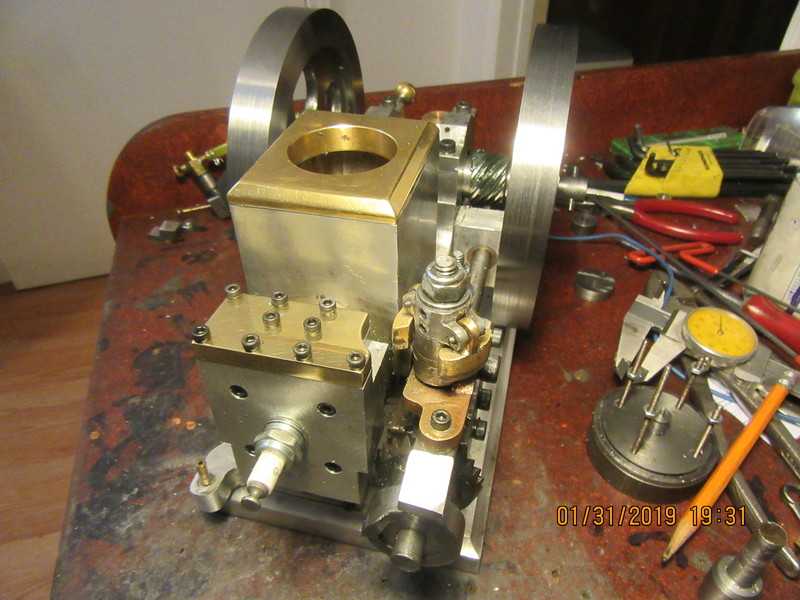

So---Here we are, hitting and missing with both flywheels on. I set the flywheels up in my lathe and turned 1/8" material from both sides to lighten them. Building the engine and getting it to run consistently was the easy part. Getting the hit and miss to work consistently has driven me to -----poetry??

What is better than Spring, and a maidens kisses

---When your hit and miss engine hitses and misses!!!

What is better than Spring, and a maidens kisses

---When your hit and miss engine hitses and misses!!!