Brian, I've lost track. Does the engine have the piston with O-ring?

If it is, what is the O-ring made of to withstand that heat?

Thanks.

If it is, what is the O-ring made of to withstand that heat?

Thanks.

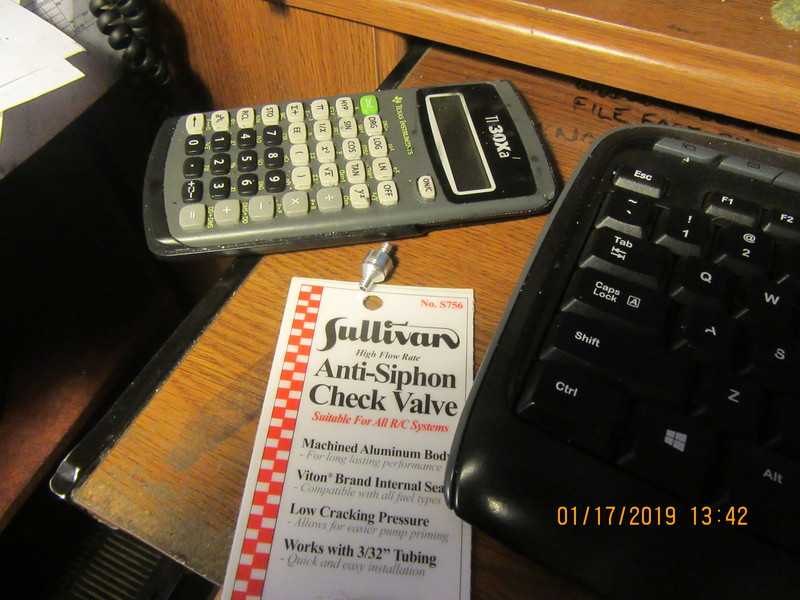

Hi Brian - i am from Australia - how can I get hold of the plans for the Hit and Miss Engine. Nev SiebyThe piston has a Viton o-ring now, which is a heat resistant material. I'm not sure if it is a polymer or something rubber based. See post #183.

Enter your email address to join: