C

Circlip

Guest

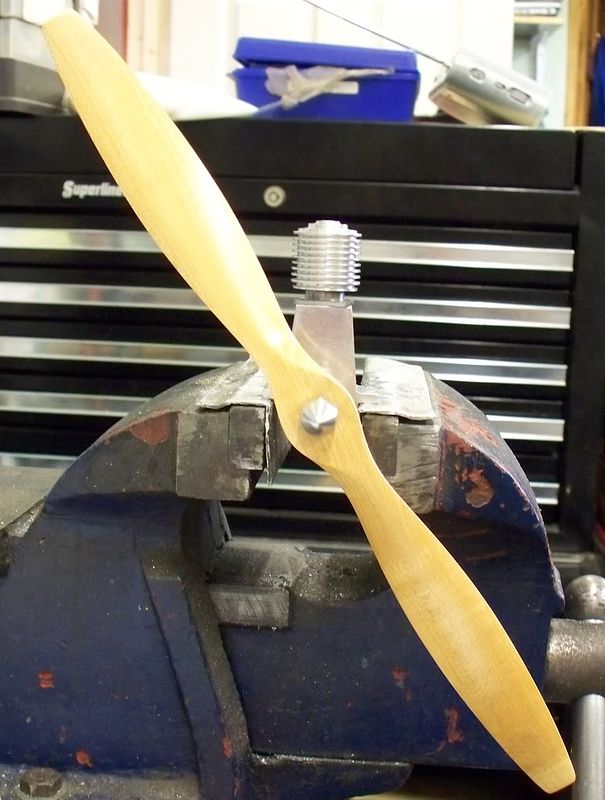

Told you hand starting was the way to go Mike 8) Sounds a bit Sloppy, Rich, Keep the big prop, better flywheel effect. Used to start Bee's, Racer, Frog2.49 and even an OS 40 with Right hand middle finger swinging right to left over the shaft. Prop was set on shaft just starting to feel compression with right hand blade on 2.( Overall position twenty to two ) you're soooooooo close, after an hours running medium speed first and slightly rich, you can gradually lean it off and increase compression. Thanks, Suuuuuuuuuuper sound, you never forget it.

Regards Ian.

Regards Ian.