You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Brians Slinky Machine

- Thread starter Brian Rupnow

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Powder keg

Well-Known Member

- Joined

- Oct 10, 2007

- Messages

- 1,091

- Reaction score

- 3

Awesome and Impressive!!!! ;o)

Wes

Wes

zeusrekning

Well-Known Member

- Joined

- Dec 21, 2007

- Messages

- 448

- Reaction score

- 0

Now that is cool. And in Christmas spirit Brian had Santa do the dialog.

:big:

Tim

:big:

Tim

A

artrans

Guest

brian thats a cool machine stupid question how did you make that flywheel from round stock or sheet it looks like about a 1/4 " thick if from sheet I assume you used a rotory table very nice would like to no how to try and make them thank you art

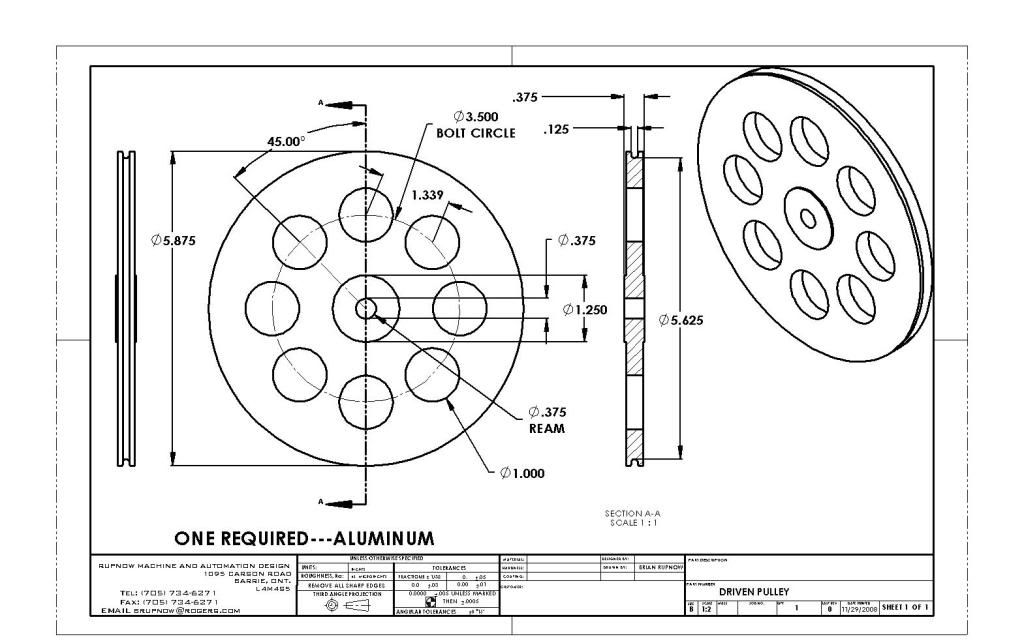

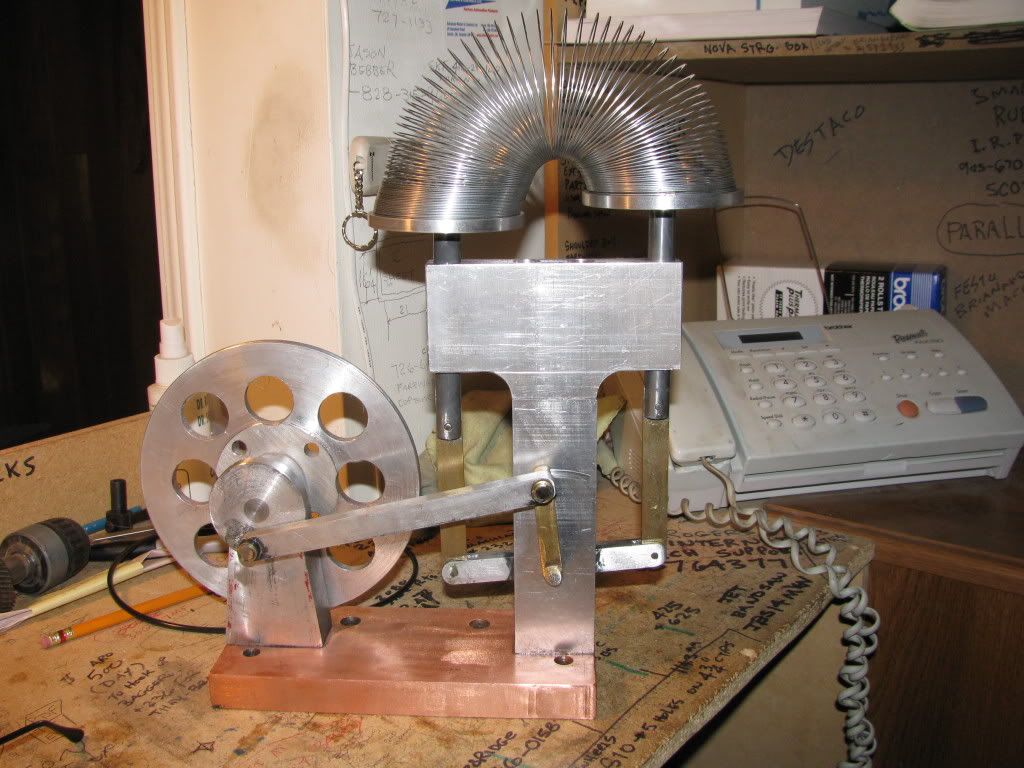

Artrans--The slinky pulley (its not a flywheel) was cut from 3/8" aluminum plate. I coated the plate with layout dye, and layed out the hole pattern with my old drafting compass. I roughed it out on the bandsaw--first cut out square, then nipped off the corners of the square at 45 degrees. My bandsaw has a 3/4" wide blade, so it doesn't cut out circles very well. I drilled the 1" diameter holes on my big old drill press, because they are cosmetic only---they have no real function . I drilled and reamed the 3/8" center hole on my mill.--The centerhole is critical, as it must be very square to the plate face so that the pulley doesn't revolve in an elipse. Since the 6" dia. pulley was too large to hold in my chuck, and I didn't want to use stand-offs on a faceplate, I scrounged around my scrap pile untill I found an adapter I had made one time for a Chev V8 waterpump nose. I machined the face of it down untill I had a 3/8" hole to fit perfectly through the centerhole in the peice of plate. I then drilled 4 small holes in the plate to accept 5/16" bolts and bolted the aluminum plate to the adapter. I mounted the adapter in my 3-jaw chuck on my lathe, then machined the outside diameter of the roughed out plate to the required profile, and "faced the exposed side. Then I undone the bolts, flipped the plate over, and "Faced" the other side.--I will attach a picture of the adapter and a detail drawing of the pulley.---Brianartrans said:brian thats a cool machine stupid question how did you make that flywheel from round stock or sheet it looks like about a 1/4 " thick if from sheet I assume you used a rotory table very nice would like to no how to try and make them thank you art

Art, also check out this thread-- a different way to skin the cat: http://www.homemodelenginemachinist.com/index.php?topic=1809.0artrans said:brian thats a cool machine stupid question how did you make that flywheel from round stock or sheet it looks like about a 1/4 " thick if from sheet I assume you used a rotory table very nice would like to no how to try and make them thank you art

:bow: Since you won't say it, I will. Very impressive! :bow:

steamboatmodel

Well-Known Member

- Joined

- Sep 7, 2008

- Messages

- 303

- Reaction score

- 7

I heard on the radio the other day that the inventer of the Slinkie, Betty James just died at the age of 90.

Regards,

Gerald

Regards,

Gerald

Tin Falcon

Well-Known Member

- Joined

- Jul 9, 2007

- Messages

- 7,207

- Reaction score

- 787

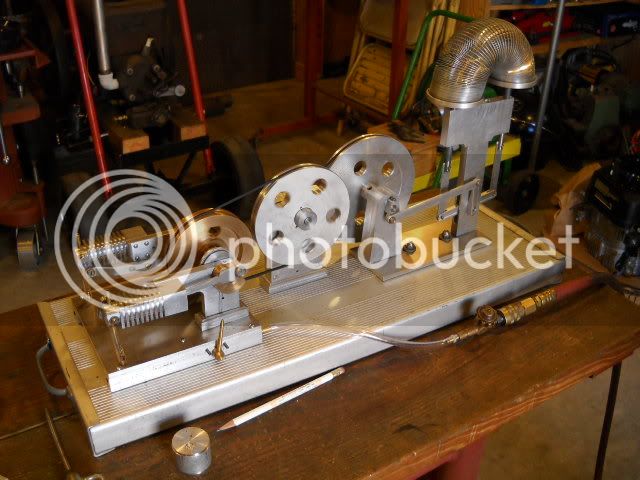

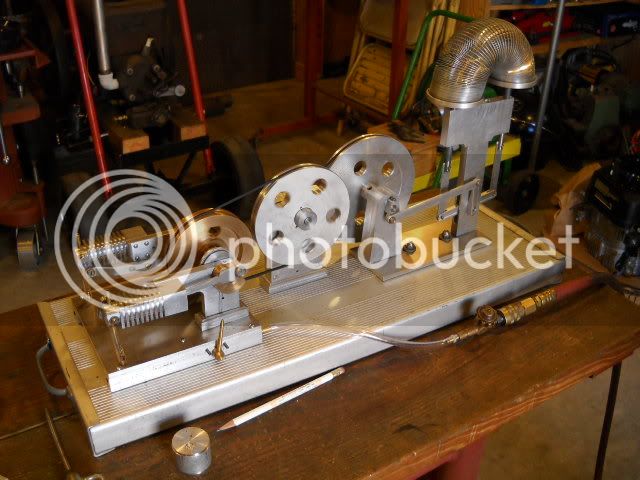

Brian, would you please post a pic of the Skinly machine completed, I have been doing the copy and paste and would like to have the finished photo in there, Please, Please, Please and thanks, Lathe Nut

lathe nut said:Brian, would you please post a pic of the Skinly machine completed, I have been doing the copy and paste and would like to have the finished photo in there, Please, Please, Please and thanks, Lathe Nut

Thanks, thanks, thanks, now I am happy like a dog with two tales, I really appreciate what you have done in sharing with all of us, take and we are ready for the next project, will be looking at the flyball governor, Lath Nut

Brians Slinky Machine, Brian made the copies for a friend of mine who is a retired machinist and a good one, this is what me made, have a video of it if I can figure out how to post it, the machines lives on, we all thank you, Lathe Nut

Similar threads

- Replies

- 4

- Views

- 419