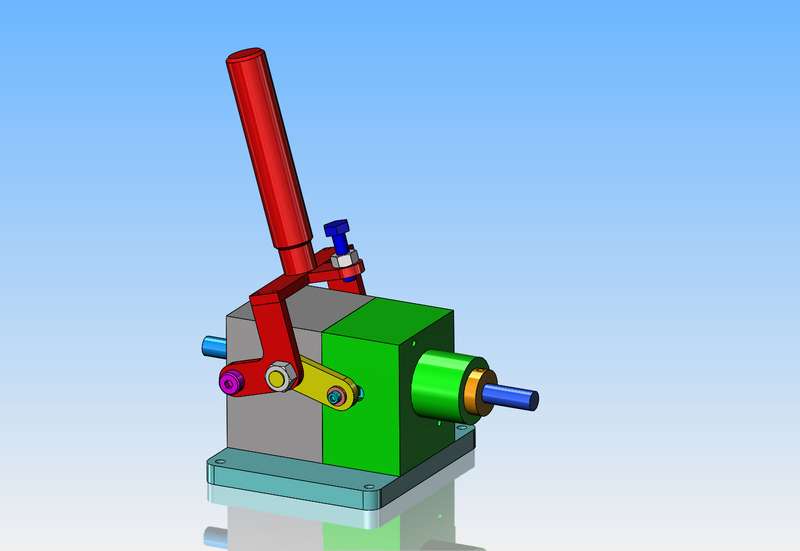

Hi Brian. Very interesting project. I´m trying to get a grasp on how it works.. Am I right if the spring will always keep an axial pressure on the bearings? That the bearings actually have to hold against the spring force in engaged position? If so I would expect some drag and short lived bearings. Maybe I misread the drawings.

I´m thinking like a car clutch. The spring tension is not pushing anything else than the clutch plate, until you press the pedal (then the crank shaft axial bearing has to take the spring tension).

Rudy

I´m thinking like a car clutch. The spring tension is not pushing anything else than the clutch plate, until you press the pedal (then the crank shaft axial bearing has to take the spring tension).

Rudy