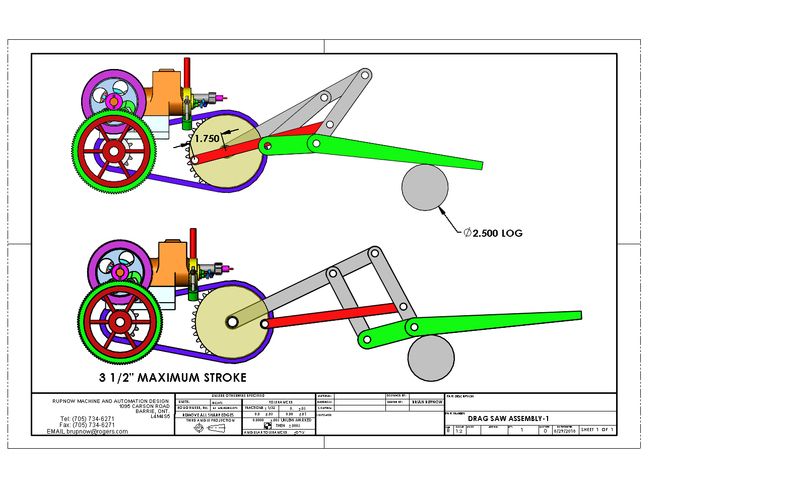

I've spent 6 hours today in "geometry world", coming up with a set of linkages that will work for the drag saw. I know of no set of equations that will let you calculate this stuff. It is more "try it and see" engineering. What I have here is a set of linkages that go through all of the required motions without binding or going into a "lock" position. Now I have to take the time to do a visual comparison between what I have and what a real drag-saw looks like. This is fun stuff, but it isn't easy. Before I cut any metal, I will build these linkages full scale in cardboard and using "stick pins" work it through all of the required motions.