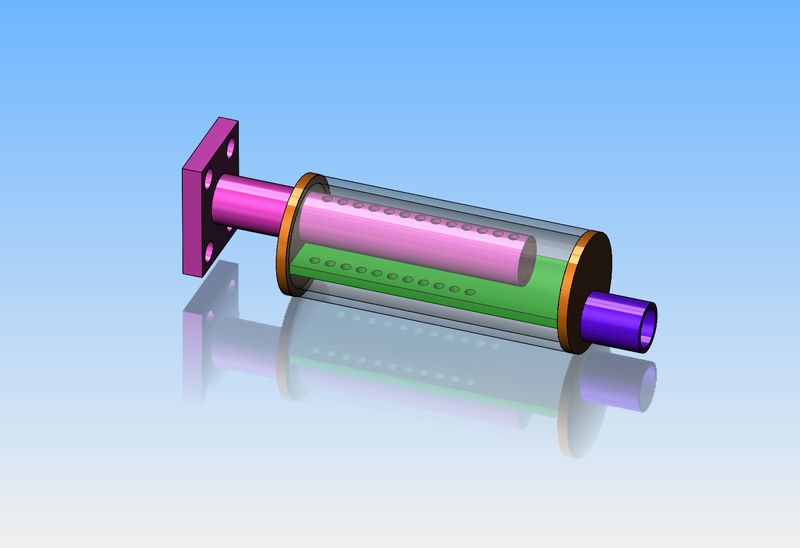

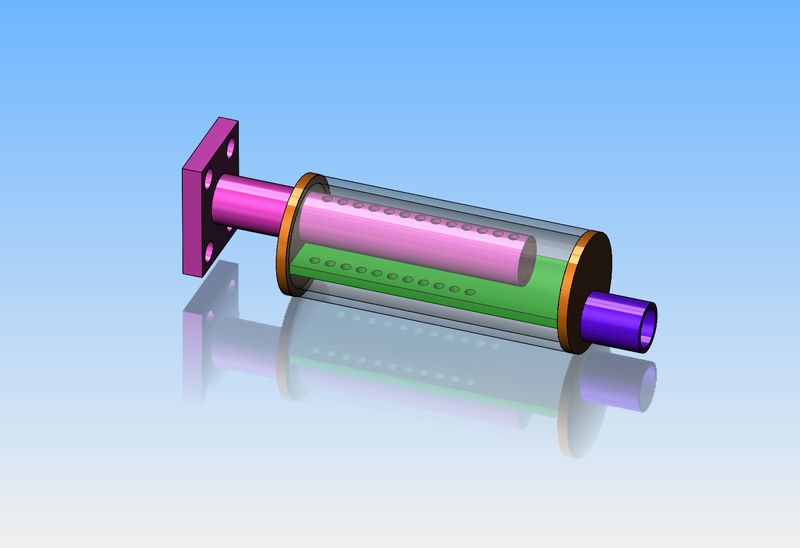

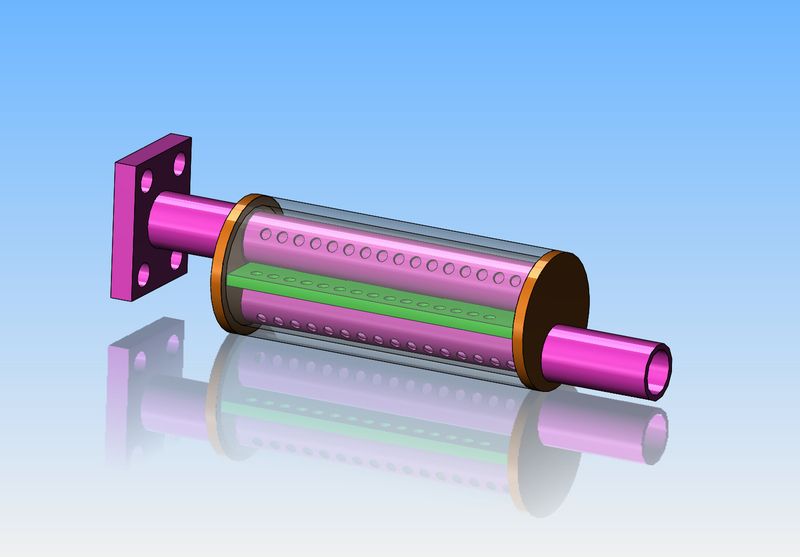

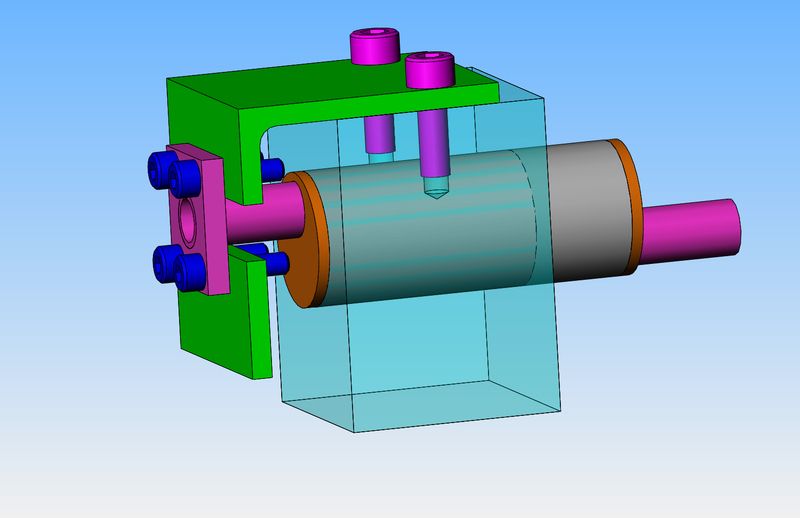

Just for the heck of it---has anyone ever built a muffler for a model i.c. engine? I have designed one this morning, based mainly on guess-work and size constraints. This muffler is designed to fit onto my flathead single cylinder engine which I designed and built a few years ago. This engine currently has a "straight pipe" on it, although the straight pipe has some fancy carving on the outside of it. Since I don't have a decibel meter, I will have to post a video showing the engine running in its current configuration, and a second video with the muffler installed on it.