This morning was time to do some "real world" tests of the governor, to determine what the maximum rpm needed to be for the stem-post to turn at, in order to get full travel of the pivoting lever arm which controls the steam valve. The video explains this as I drive the governor through it's full range of movement.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Double acting Double Oscillator

- Thread starter Brian Rupnow

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

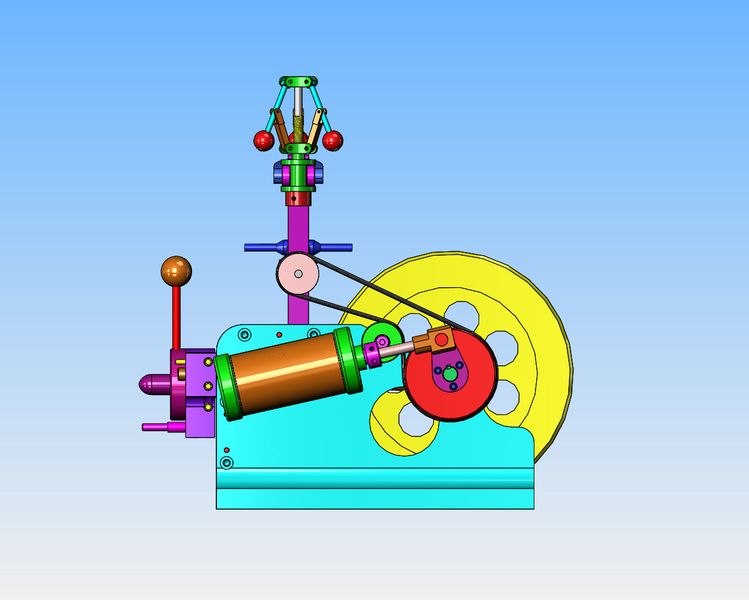

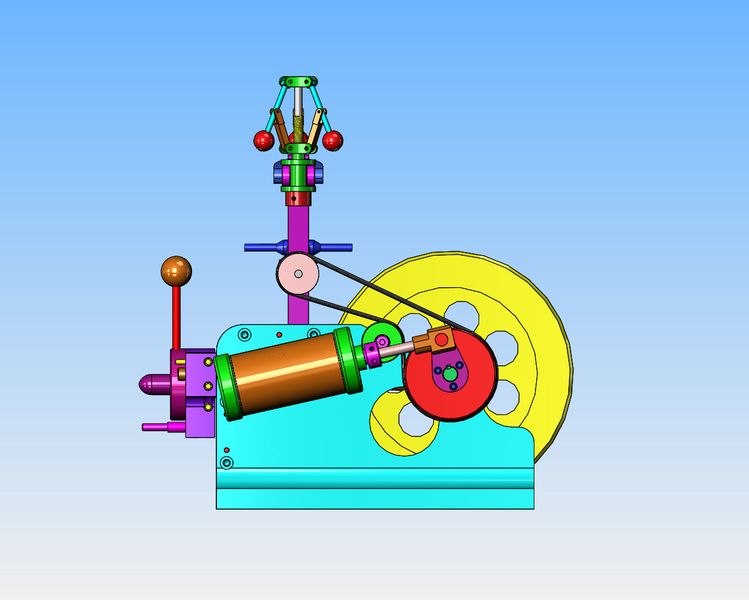

In order to mount and drive the governor at the right speed, I will have to use a "bend pulley" which mounts to the side of the main frame with a shoulder bolt. This will keep everything (the o-ring drive belt) from interfering with the oscillating cylinder.

Doing a bit of "real time" testing here to see if the governor is spinning fast enough to take advantage of it's full range of motion with the engine running at a reasonable rpm.

Very interesting result this morning. I tried exactly the same test this morning (as shown in the video) but with the compression spring removed from the stem post. This gave full movement of the governor arms as I wanted, and made the governor much more responsive at a lower speed. Gravity seemed sufficient to return the balls into "low speed" mode when I slowed down the engine. The only thing I am absolutely sure of after dicking around with mechanisms like this for 50 years---Gravity only works when you are watching it. As soon as you turn your back, something screws up. I'm off now to buy a lighter compression spring.

Hello Brian, Notice you are testing the governor in a horizontal position. Would that not put out of balance into effect instead of vertical operation. I have finished my 3 ball governor and am following this thread

closely Norm

closely Norm

I have spent the entire day fitting the governor to the engine, building and mounting a bend pulley, and changing out the spring on the stem-post for a lighter spring. I'm happy with the results so far, but it has eaten an entire day to get to this stage.

Norm--It might throw it out of balance a bit, but not enough to make a difference in what I was testing for. This type of governor will work in either vertical or horizontal position, but I wouldn't trust gravity alone to return the balls into "low speed" mode, when the stempost is vertical.

Cymro77

Cymro77

Fascinating seeing your brain at work Brian. I am learning as well. Thanks for sharing.

Either the parts are getting more complicated or else I'm getting slower.---Probably both!!! I made the new front end for the governor (which will be part of the steam valve), and made the brass bushing that lines it. In the middle of all that my lathe quit, and when I went to check the glass fuse the entire fuse holder fell apart in my hands.---Fortunately for me, I knew that they had plastic fuse holder assemblies at Sayal electronics across town, so I went over there, bought one, brought it home and after a little soldering and finessing my lathe was up and running again.

I spent 8 hours today doing a 1 1/2 hour job. BAH!! HUMBUG!! OINK!!! The steam valve started out with a center rod 3/16" diameter.--It leaked. Then we went for a 7/32" center rod---it leaked. Then we tried a 1/4" center rod---it leaked. Finally I went with a 9/32" center rod and it leaks such a small amount that I think it is acceptable. And of course every time I went up 1/32" in rod diameter I had to go up 1/32" in reamer size for the rod to fit into. Days like today I wish I had taken up needlepoint as a hobby instead of machining.

RonGinger

Well-Known Member

Look at the other side of this- you spent a whole day working on your hobby. Who cares how much got done? We dont get paid by the hour we get our satisfaction from working on our hobby. Does it really matter if you made one part, or a whole engine?

Good point Ron. However, no matter how much I like it, I reserve the right to whine a little bit when things go all screwball on me.---Brian

I'm pleased to report that the governor works quite well on this engine. For projects that were built 3 or 4 years apart and never intended to run together, they work together quite well. I have some clean-up work to do and some pivot pins to shorten, and then I will make a video to post.---Brian

Cymro77

Cymro77

Just luv them flowerescent tubes!!! Must be so they can be found in the haze of steam in a Canadian Winter.

. Can't wait to see her run!

. Can't wait to see her run!

And here, as promised, is a final video of the 3 ball governor running on the dual oscillating engine.

JohnBDownunder

Well-Known Member

- Joined

- Mar 1, 2012

- Messages

- 109

- Reaction score

- 28

Thank you Brian,

As usual an excellent and informative posting.

One thing that I am wondering, does the engine still run in reverse? I'm sure it did previously and cannot see why it would not with the governor.

thanks again for posting.

John B

As usual an excellent and informative posting.

One thing that I am wondering, does the engine still run in reverse? I'm sure it did previously and cannot see why it would not with the governor.

thanks again for posting.

John B

Yes, the engine still runs in reverse. The governor still works too---governors are not directional at all, they will run either way.---Brian

Norm--there are ways that rpm can be dialed in with a governor, but not in this particular case. On the type which has the adjustable counterspring like in post #134 you can dial in the optimum speed you want the engine to run at.

Cymro77

Cymro77

Beautiful work. Great videos and photos throughout the Thread. Another masterful piece of work! Thank you for sharing.

Only one question - What is next.

Only one question - What is next.

Similar threads

- Replies

- 413

- Views

- 38K

- Replies

- 148

- Views

- 20K

- Replies

- 6

- Views

- 775