Hello everybody.

I got able to do some more work done this week. Still on the block.

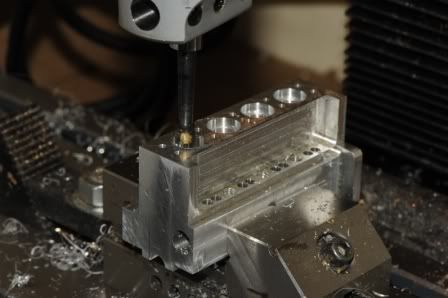

As I received the boring head I ordered few weeks ago, I was able to finished the liners holes and water jackets. The tool showed to be very precise holding the dimensions and easy to adjust. Photos ahead!

Counterbore operation

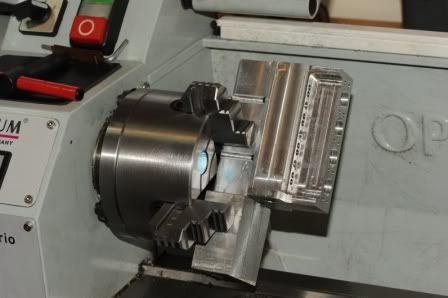

Next operation was the water jackets.

I tried to do it on the lathe, however I did not feel safe with the setup, so I had to use the traditional dividing table and a grooving mill.

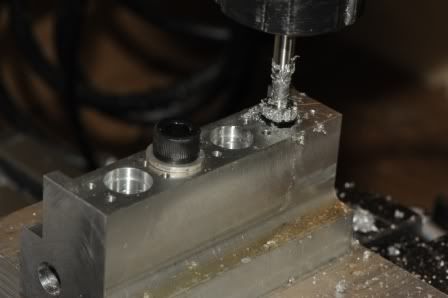

Here is where I'm so far.

No internal parts done so far. The head still need all the holes.

Thanks.

Edi