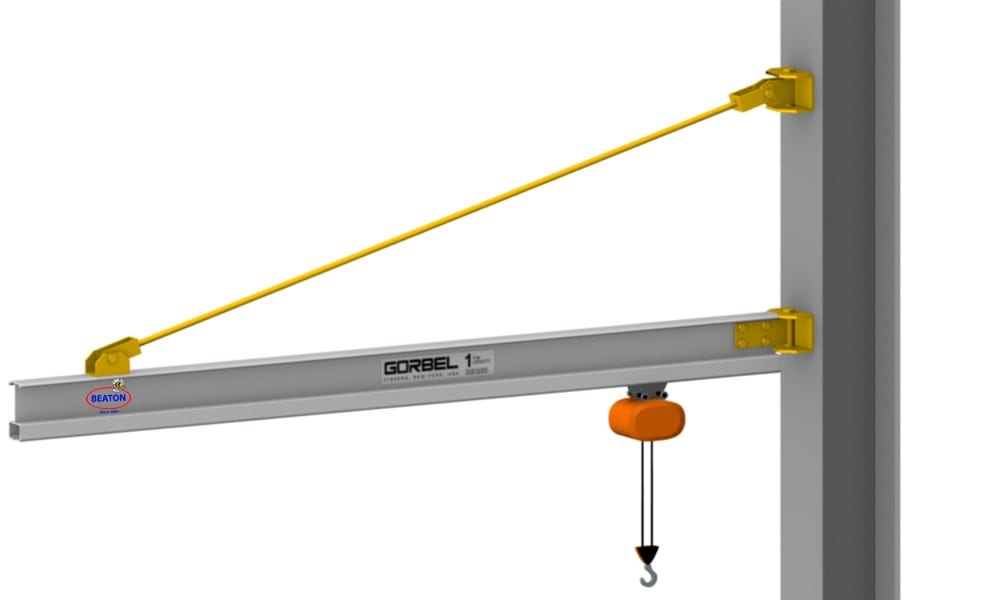

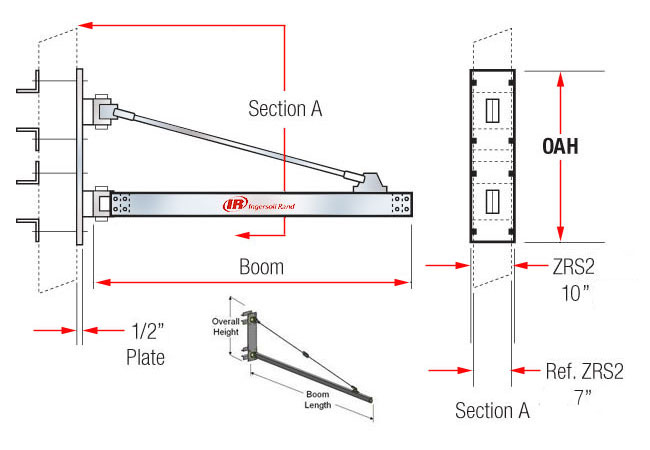

I have not yet started, I must get the material, however, thanks to the valuable suggestions, however I do not have to lift big loads I put as maximum capacity 500 kg, but I do not think that ever lift a load so heavy, it will be like a crane of what are built on the boats, a column a swivel crosspiece and a hoist with a diagonal tie rod to support the structure and the cantilever load, I do not know what is called in marine jargon a similar lifting frame, nothing mammoth to clarify, thanks again anyway if you have other advice, please, thank you

https://publicqa.gorbel.com/images/...es/wb10077096c36eb6e608cbd72ff000019dfa3.png?

sfvrsn=5

http://shweibos.com/wall-mounted-ji...for-sale-jib-crane-services-jib-best-creative

http://www.cisco-eagle.com/catalog/...lbs-cap-14-boom-length-44h-w-38-in-air-supply

Your design will work. I would have the cable angle steeper. Make the column higher so the cable is more than 45°. The column itself 8" square I assume is good for much more weight than you could get into a garage. I do not see a dimension for the lift arm, appears to be at least 6" high. Plenty strong. The last pic appears to be a solid member of round stock, other pics appear to be a cable. Either will do.

As long as the 5/8" plate is anchored well on the top , no danger of tipping over.

mike