toolznthings

Project of the Month Winner

Stopping chatter on lathe turnings can be a real problem, especially on long small diameters and even larger turnings.  When all else fails with speed, feed, and tool radius the following solution usually works.

When all else fails with speed, feed, and tool radius the following solution usually works.

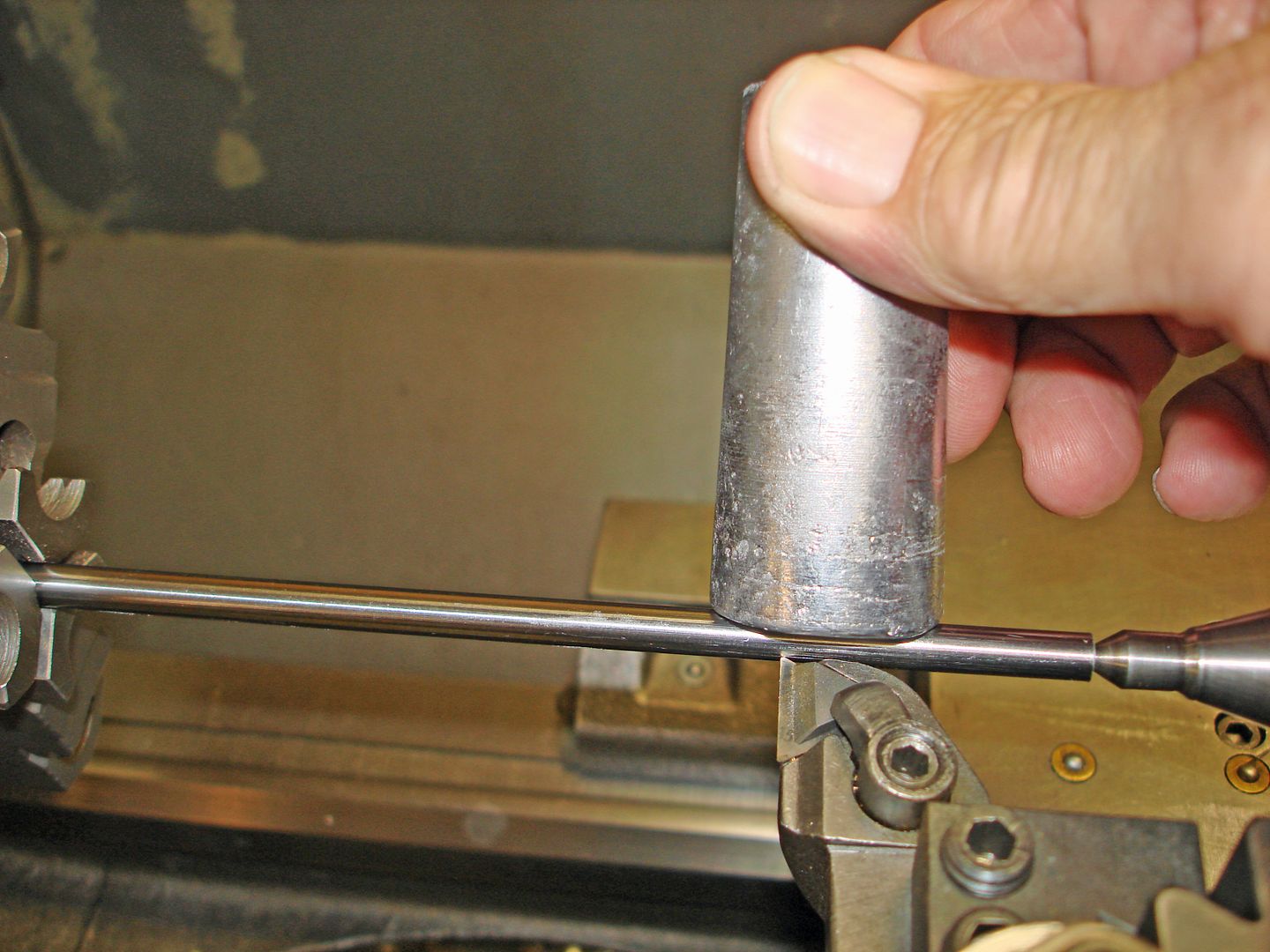

I have made several small hand held lead " hammers " about three inches long and one inch plus in diameter. Handy for numerous uses around the shop.

Pictured is how I would use the lead when turning. ( an example ) I would use the smallest tool nose radius practical, carbide or HSS, adjust my RPM and feed and let the lead slug ride on the work piece at the point where the tool is cutting. It is not necessary to apply heavy force as to effect the cutting diameter, but enough contact to absorb the vibrations from the cut. Follow along the cut as needed. A drop of oil also helps.

Doesn't always work, but has saved the day more than once when all else has failed.

I have made several small hand held lead " hammers " about three inches long and one inch plus in diameter. Handy for numerous uses around the shop.

Pictured is how I would use the lead when turning. ( an example ) I would use the smallest tool nose radius practical, carbide or HSS, adjust my RPM and feed and let the lead slug ride on the work piece at the point where the tool is cutting. It is not necessary to apply heavy force as to effect the cutting diameter, but enough contact to absorb the vibrations from the cut. Follow along the cut as needed. A drop of oil also helps.

Doesn't always work, but has saved the day more than once when all else has failed.