Good theory and good thinking Brian,

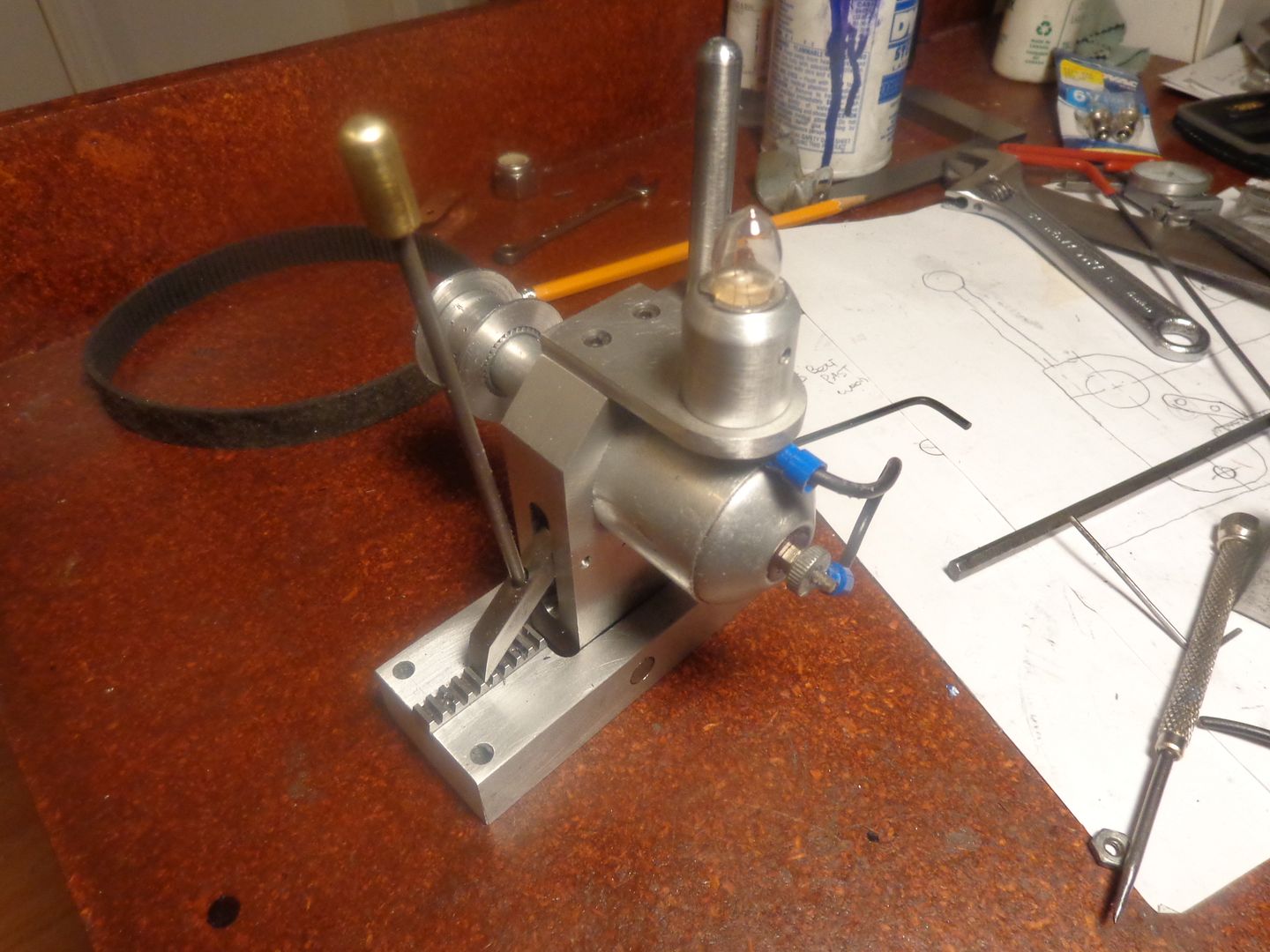

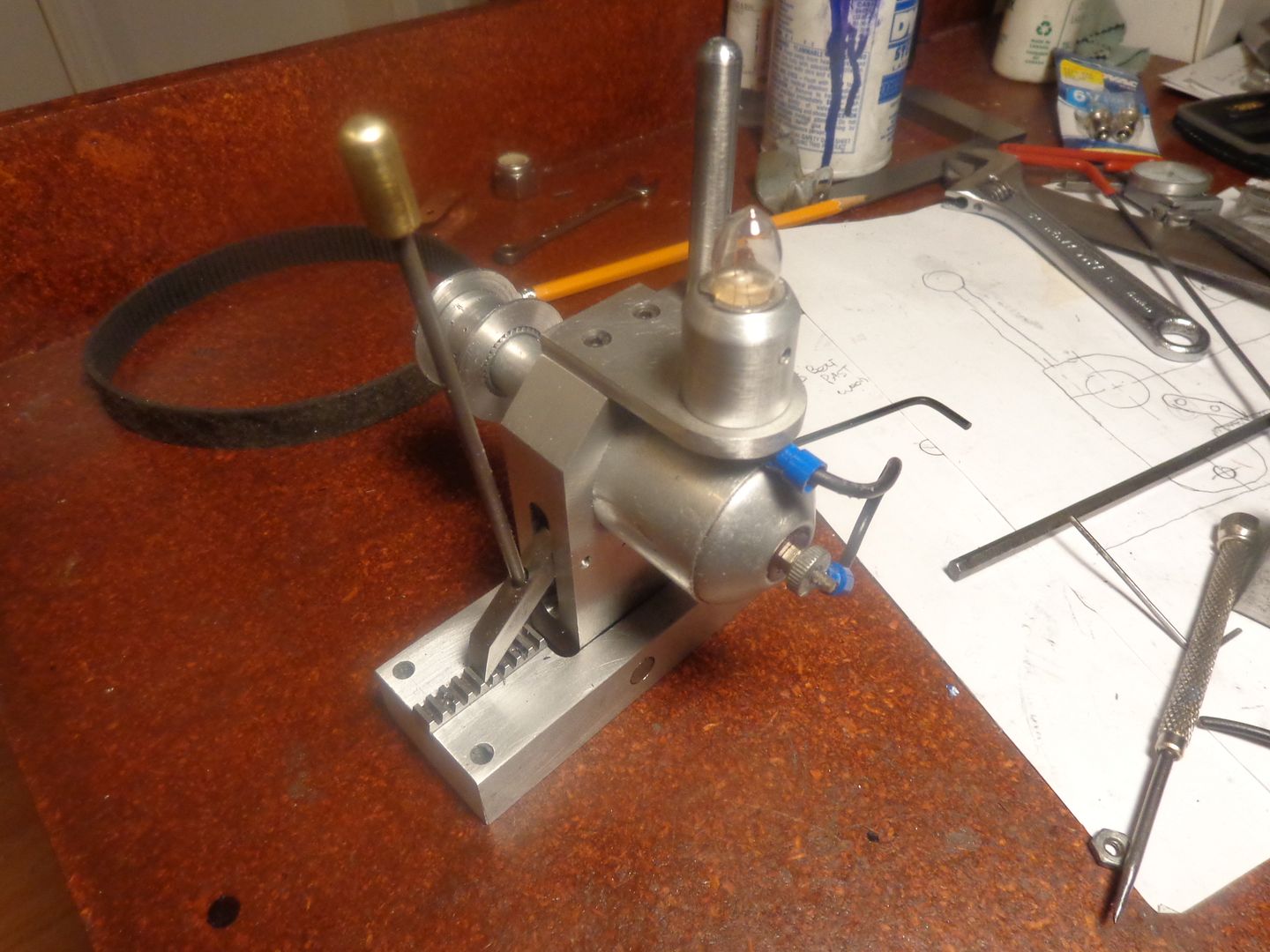

It makes me think also, as I wanted to build my own mini micro carb some time in the near future.

I am playing with thoughts of a primary and secondary equipped throttle system where you use the secondary supply to partly control the primary supply, basically controlling what the primary throttle can deliver.

Think of a screw control like you have with an additional screw control within it, and a fuel supply large enough to feed both full open.

Work with the first (no load), and open the second if demand dictates more fuel.

The idea in my head is to keep it verrry simple and that makes it harder, but I'll think of something.

Should the time come for bigger coal, you can then simply open up the primary control in addition to the secondary or control the amount of extra flow to the primary, and in this way feed double or some proportion thereof bigger than the secondary can deliver by its lonesome.

If this is confusing, think of how a carburetor has primary and secondary jets, or idling, intermediate and running feed passages in the smaller ones to overcome the dead spots or starvation at a higher required flow.

The big problem has always been the smooth transition from one to the other in order to keep the engine fat dumb and happy.

Carburation is still a big thing in my vocabulary of things to invent as I have slugged and toiled with the rather crude and inefficient early designs (I know..."old School") in my youth.

The Harley "linkert carburator" comes to mind lol, basically a bronze tube with a needle valve, a jet and a fuel feed

I am not intending to break any barriers here, but rather want to come up with something to, lets say, enhance the way fuel gets delivered for the demand, and not that demand should suffer because of inefficient delivery in more than one way, and still keep it simple, that's the thing. (and mini.)

If all else fails use a BIGass screw!

In the aircraft business where I was an apprentice AME for a bit (hated the job, but still like aircraft and flying.) there is a saying that everything is a compromise in aviation.

I always thought that that was the dumbest saying and attitude.

If there IS a way, let's find it! ( Me..., the Einstein who's going to change the world lol.) :hDe:

Just saying!

Beers...., er...., Cheers, J.