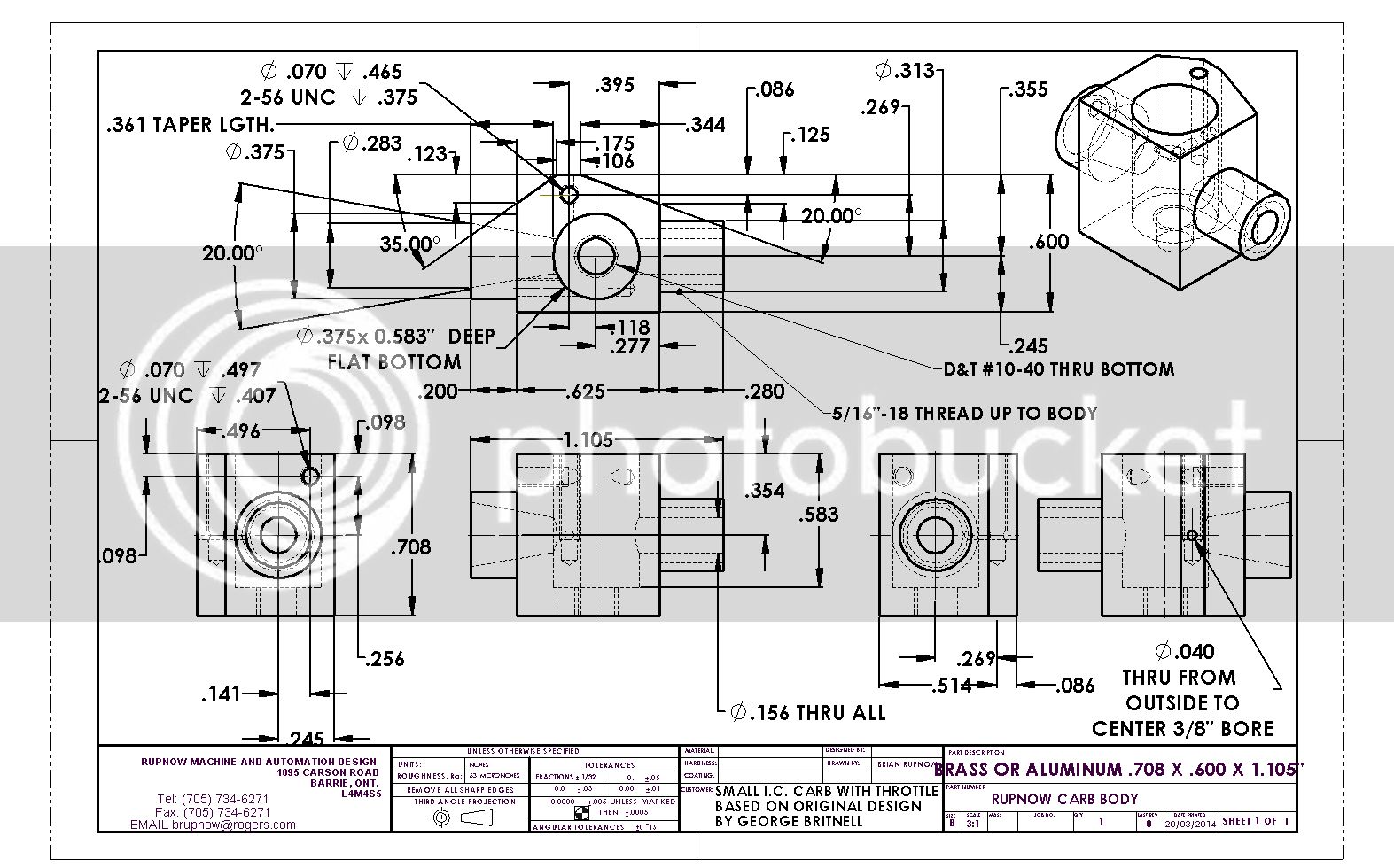

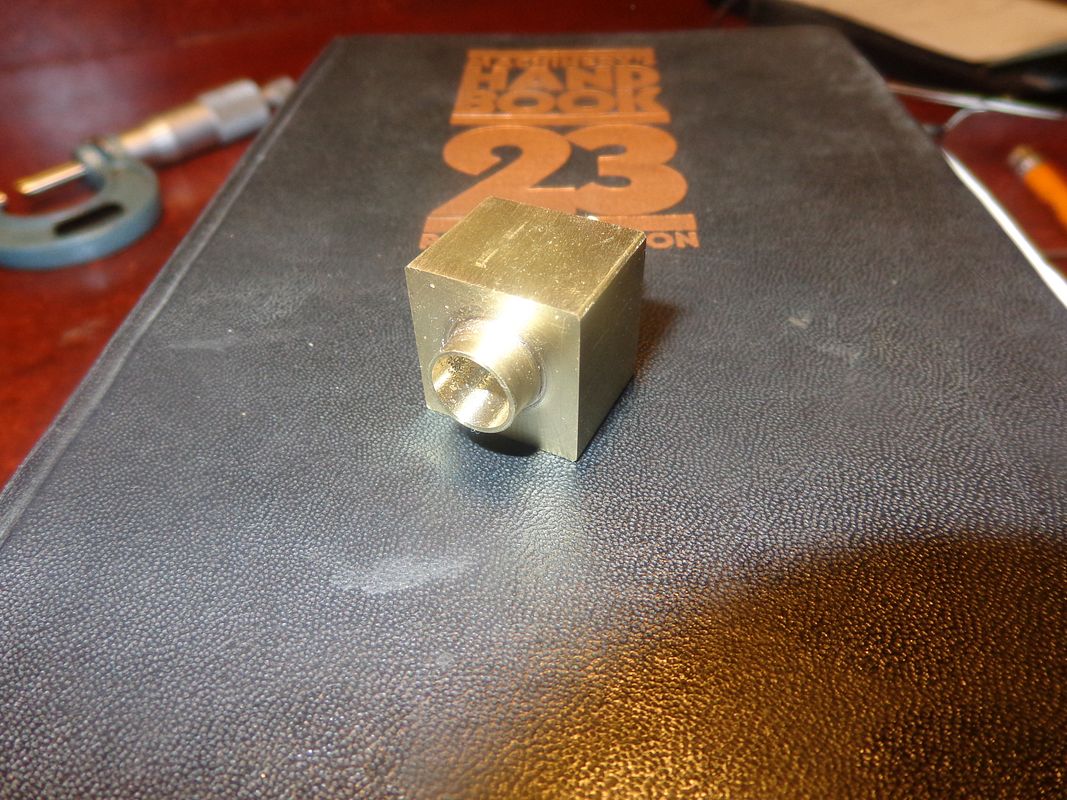

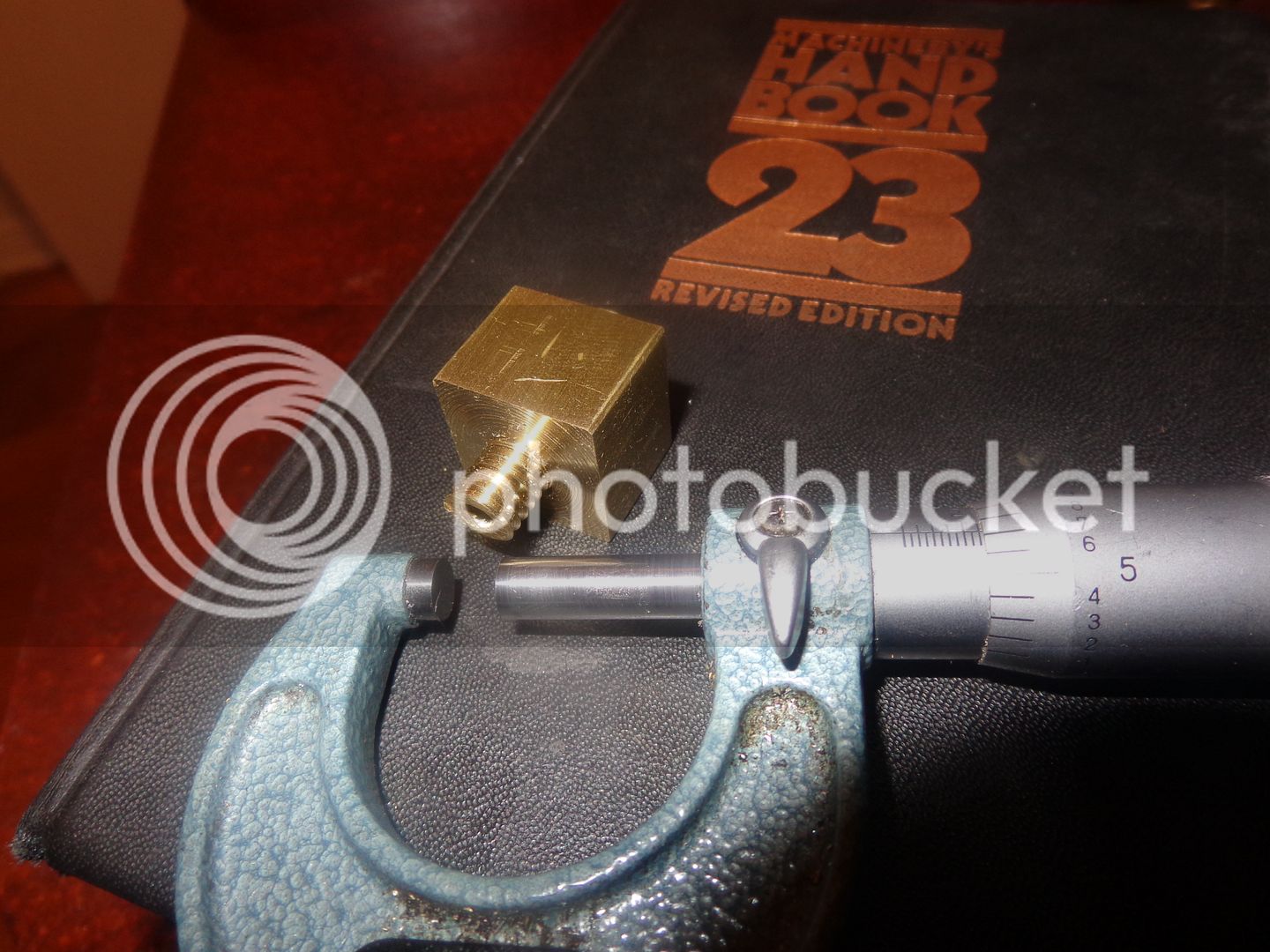

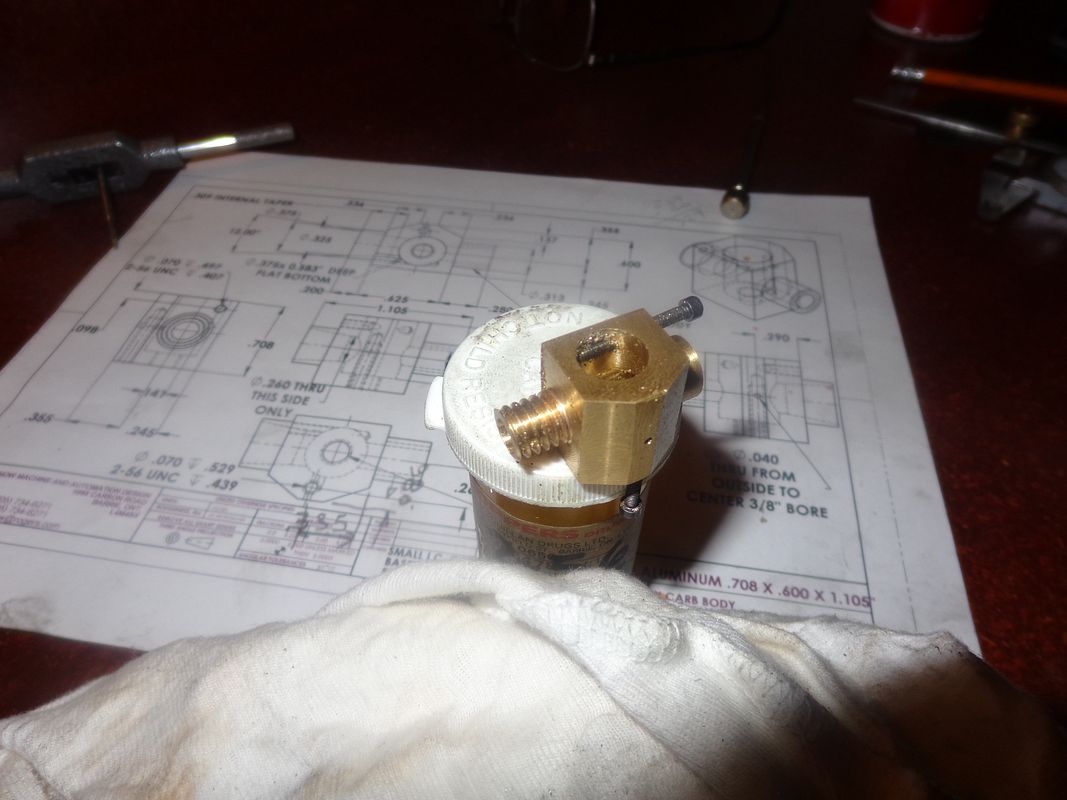

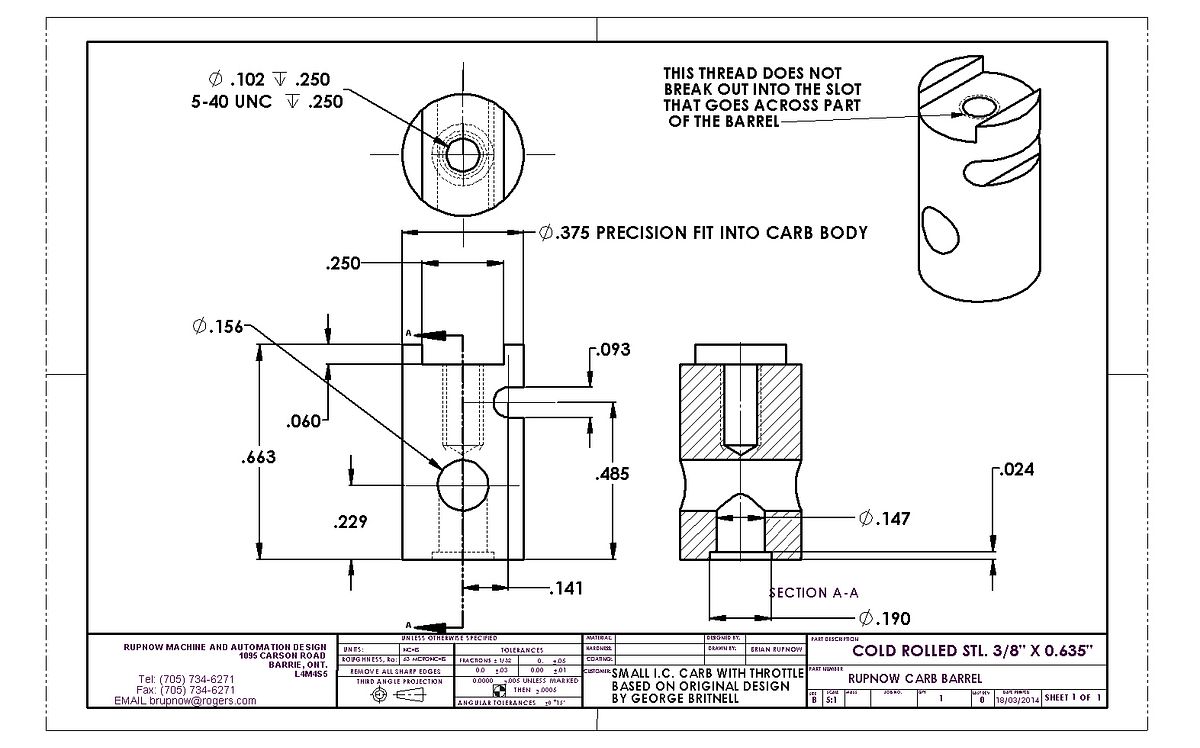

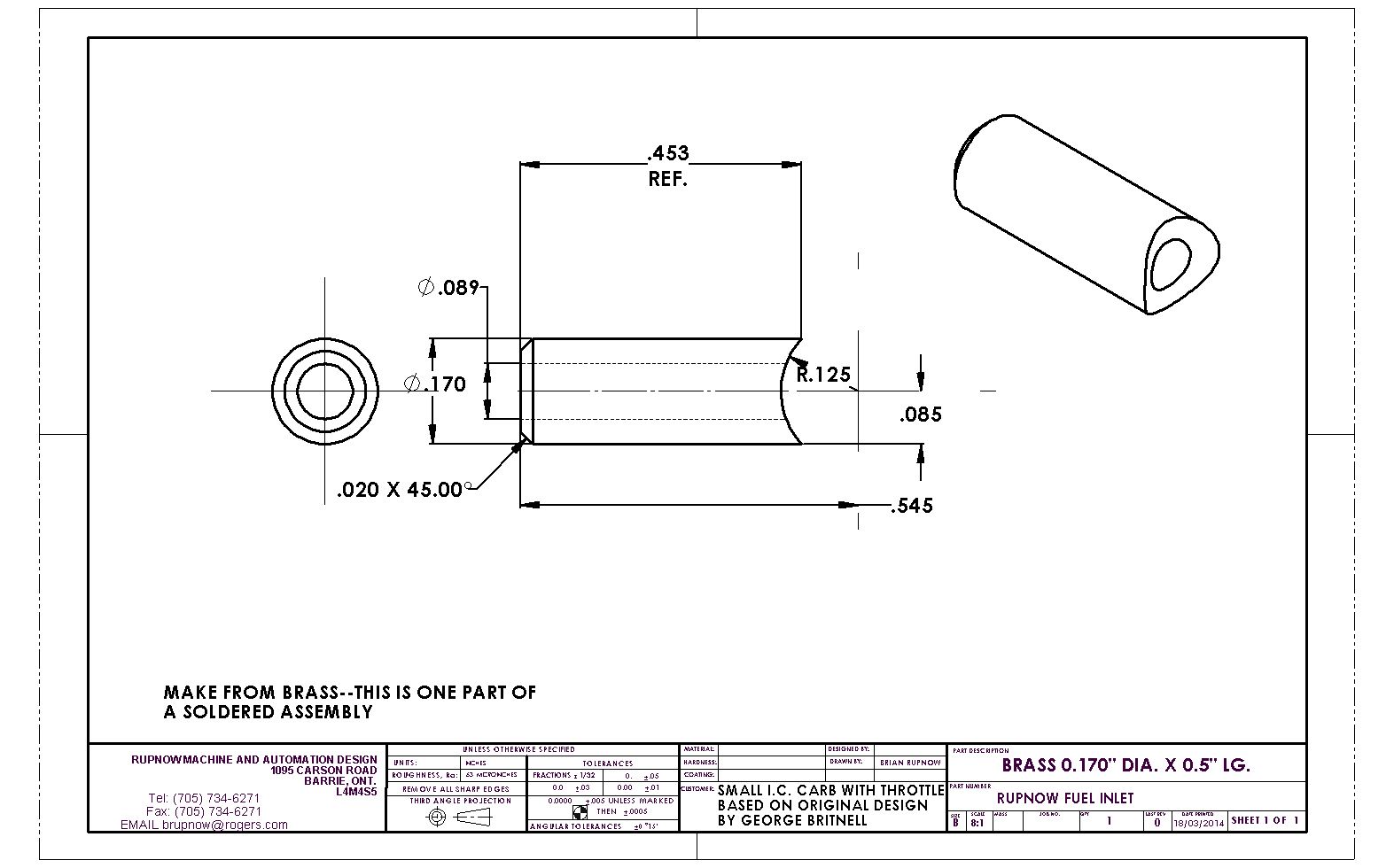

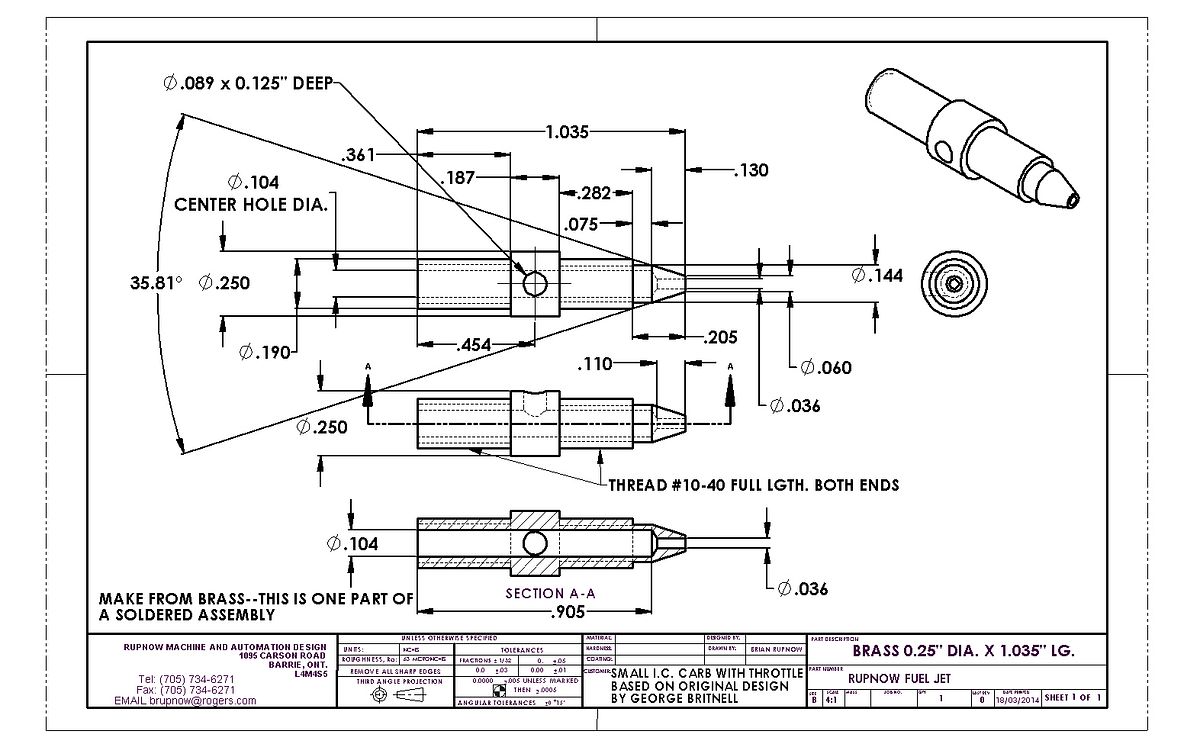

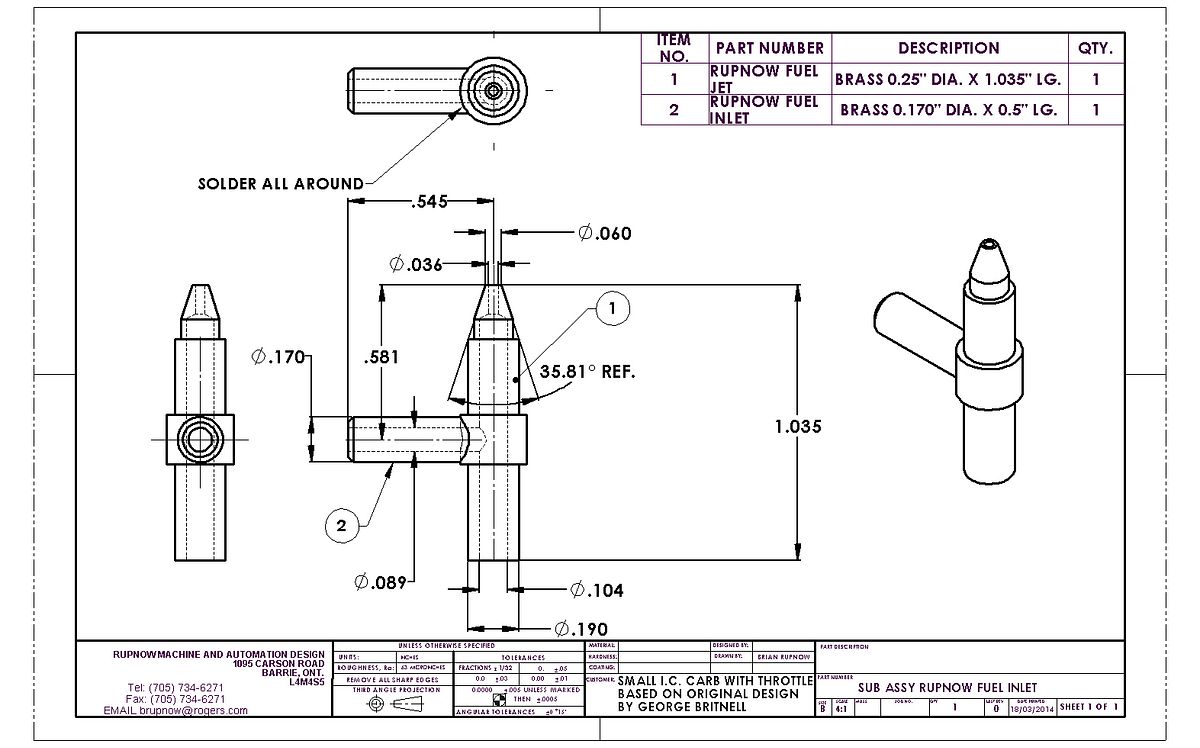

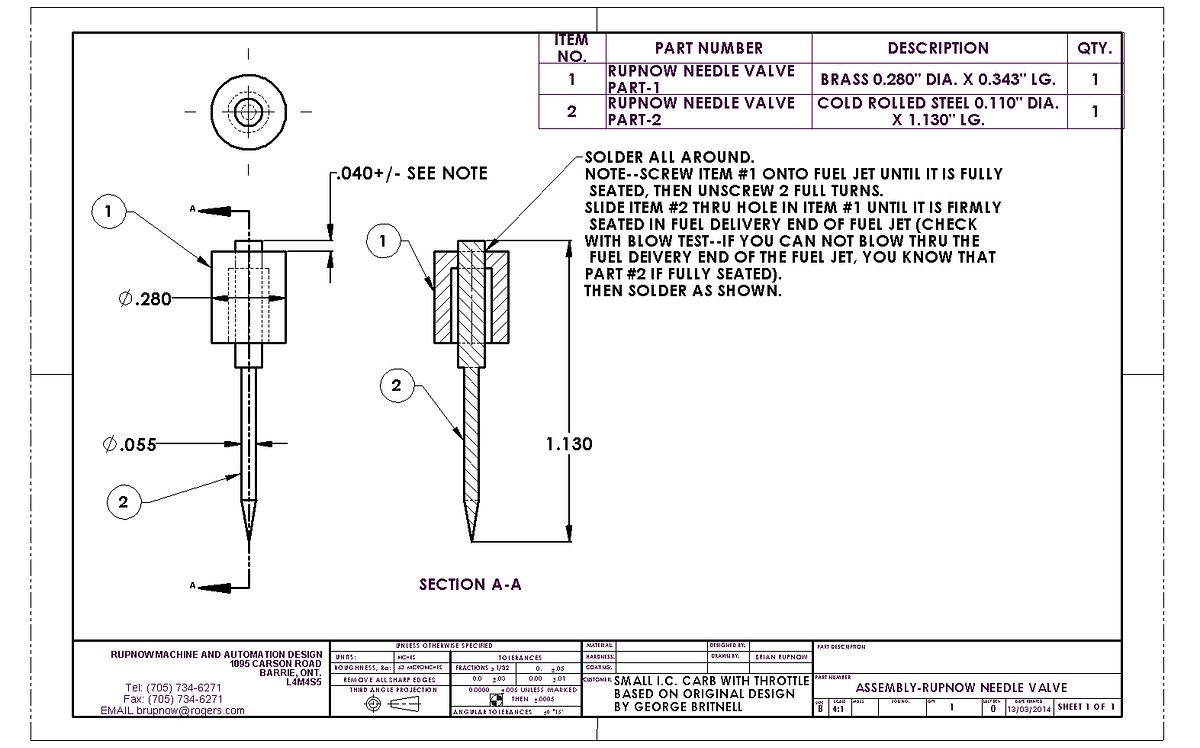

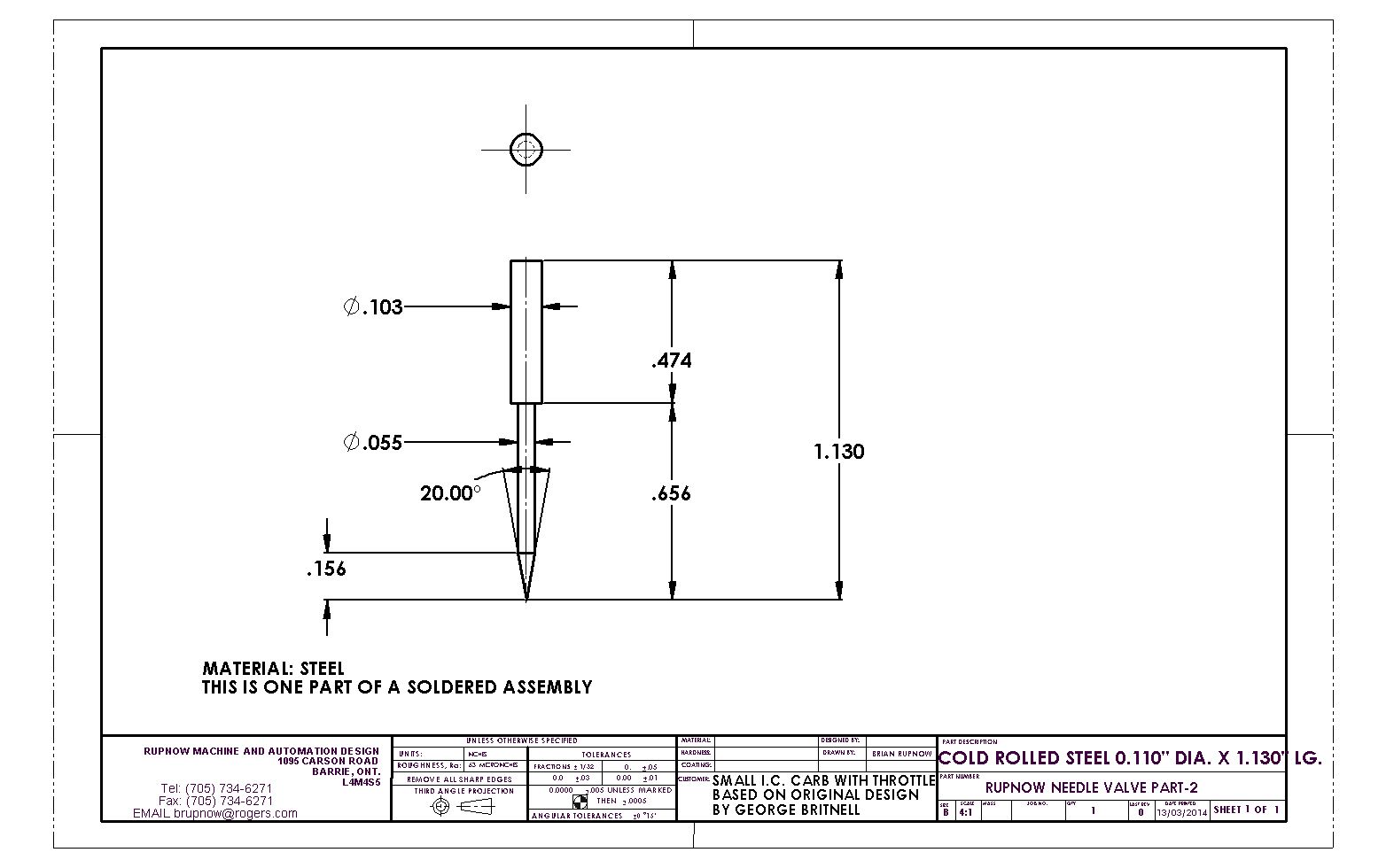

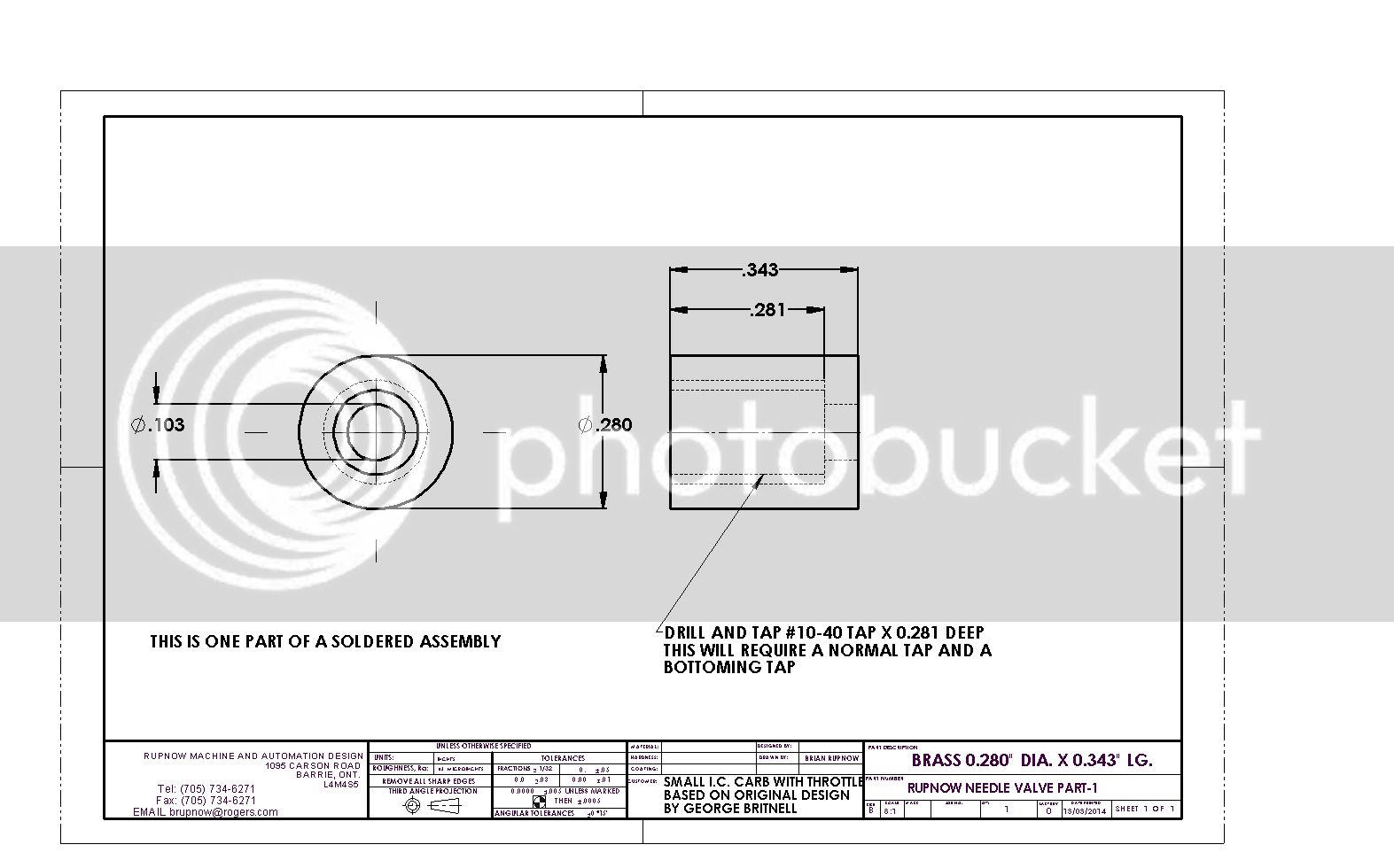

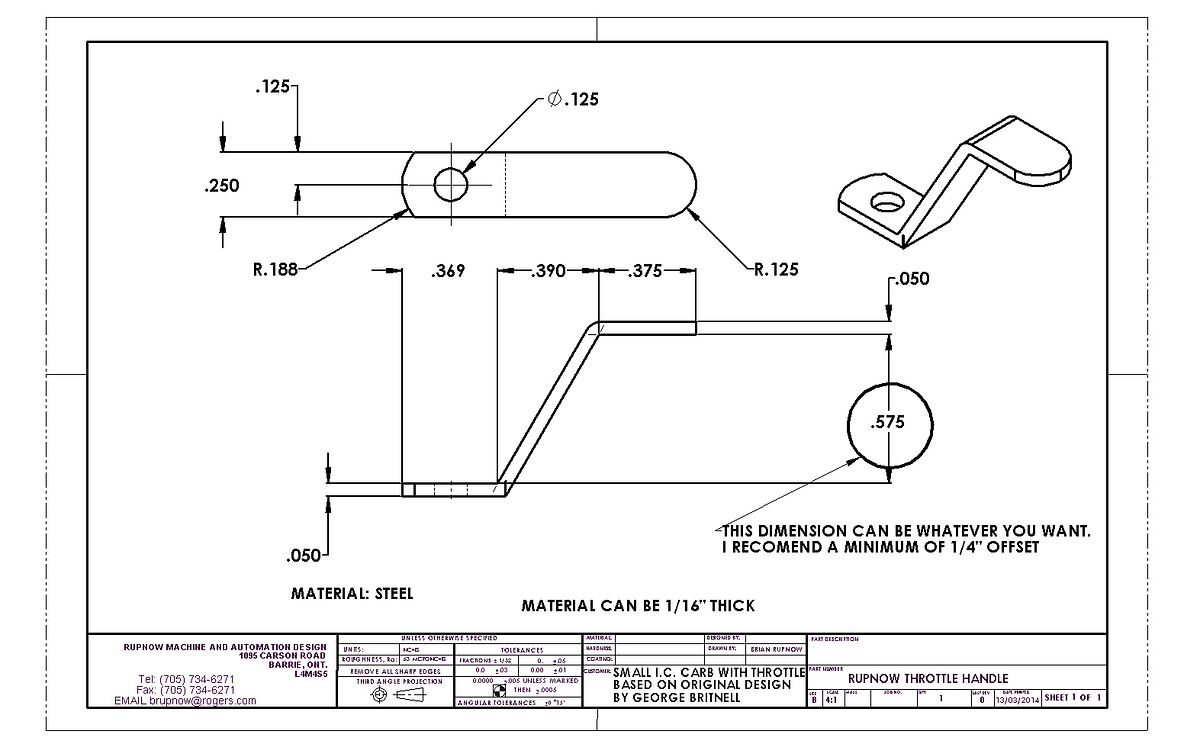

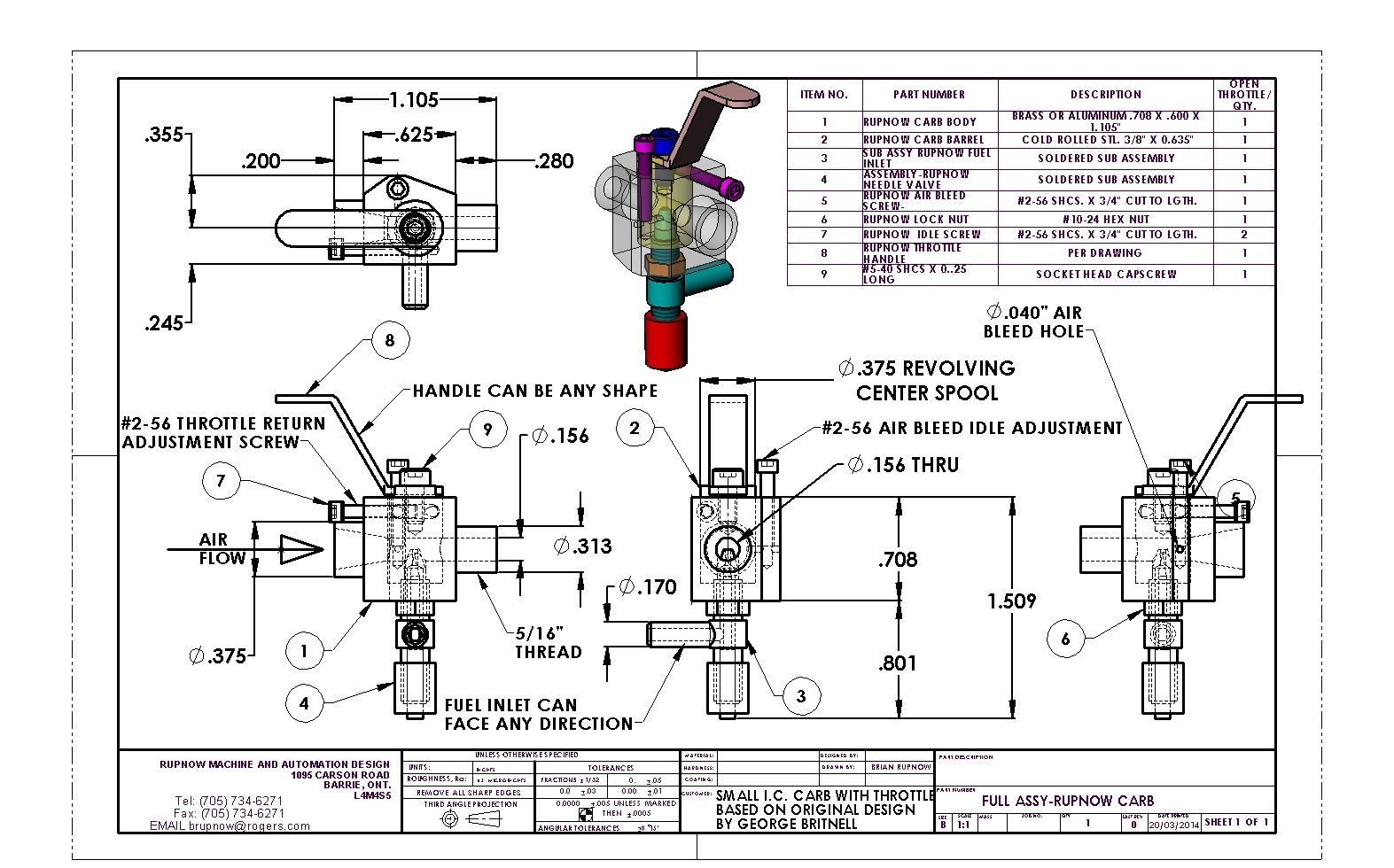

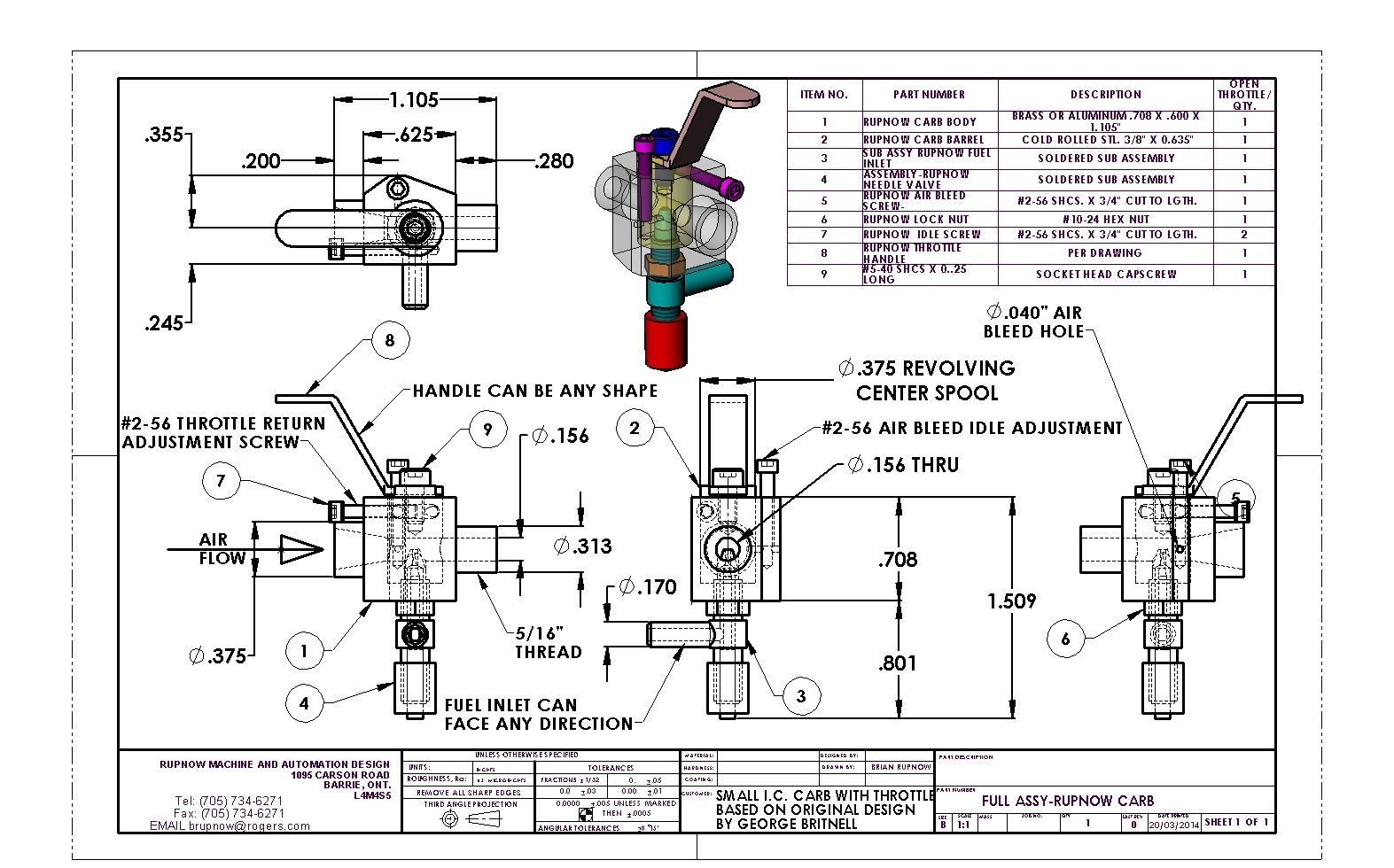

Myself and another fellow from the HMEM forum have been doing a lot of research to find a small I.C. carb with a throttle on it. Hit and miss engines do not have a throttle on them, as the speed is controlled by the governor system. There is no throttle in those carbs--they run "wide open" all the time, as anyone can attest to who has ever had the misfortune to have the governors stick on their hit and miss engines. However, not all of the model engines we build are hit and miss style. Now don't get me wrong.--There are lots of carburetor designs out there for I.C. engines, but they are HUGE compared to the size of the engine itself. We have been searching for carbs that won't look out of place on engines from 1/2" to 1" bore with a single cylinder. After looking at many different plans, we have decided that the best design out there is a design originally put together by George Britnell for use on his 4 cylinder engine. The only fly in the ointment is that George's carburetor has a relatively large bore in it at 0.260" diameter. On the small I.C. engines that I build, they depend on air flow thru the carb venturi to create enough vacuum to pull fuel up to the carb from the fuel tank. If the bore of the carb is too large, the resulting vacuum created by too large a carb bore compared to the engine displacement won't create enough venturi vacuum to suck up the fuel to the needle valve spray "nose". I have taken Georges carburetor and redesigned it to accommodate a bore of 0.156" in the venturi area. This has allowed me to make the overall carb body smaller and to make the attendant air bleed screw and idle speed screw smaller as well. George knows I am doing this, and has even offered up some helpful advise. I am going to build this carb, and use the Webster engine I built a few years ago as my "test bed". Stick with me, and I will post detail drawings as I progress. It will probably be safer to wait until the end of the build to actually download any drawings, because they may change as this thing develops.----Brian

http://s307.photobucket.com/user/Br...w013/FULLASSY-RUPNOWCARB_zpsacdb7dd1.jpg.html

http://s307.photobucket.com/user/Br...w013/FULLASSY-RUPNOWCARB_zpsacdb7dd1.jpg.html

http://s307.photobucket.com/user/Br...w013/FULLASSY-RUPNOWCARB_zpsacdb7dd1.jpg.html

http://s307.photobucket.com/user/Br...w013/FULLASSY-RUPNOWCARB_zpsacdb7dd1.jpg.html

Last edited: