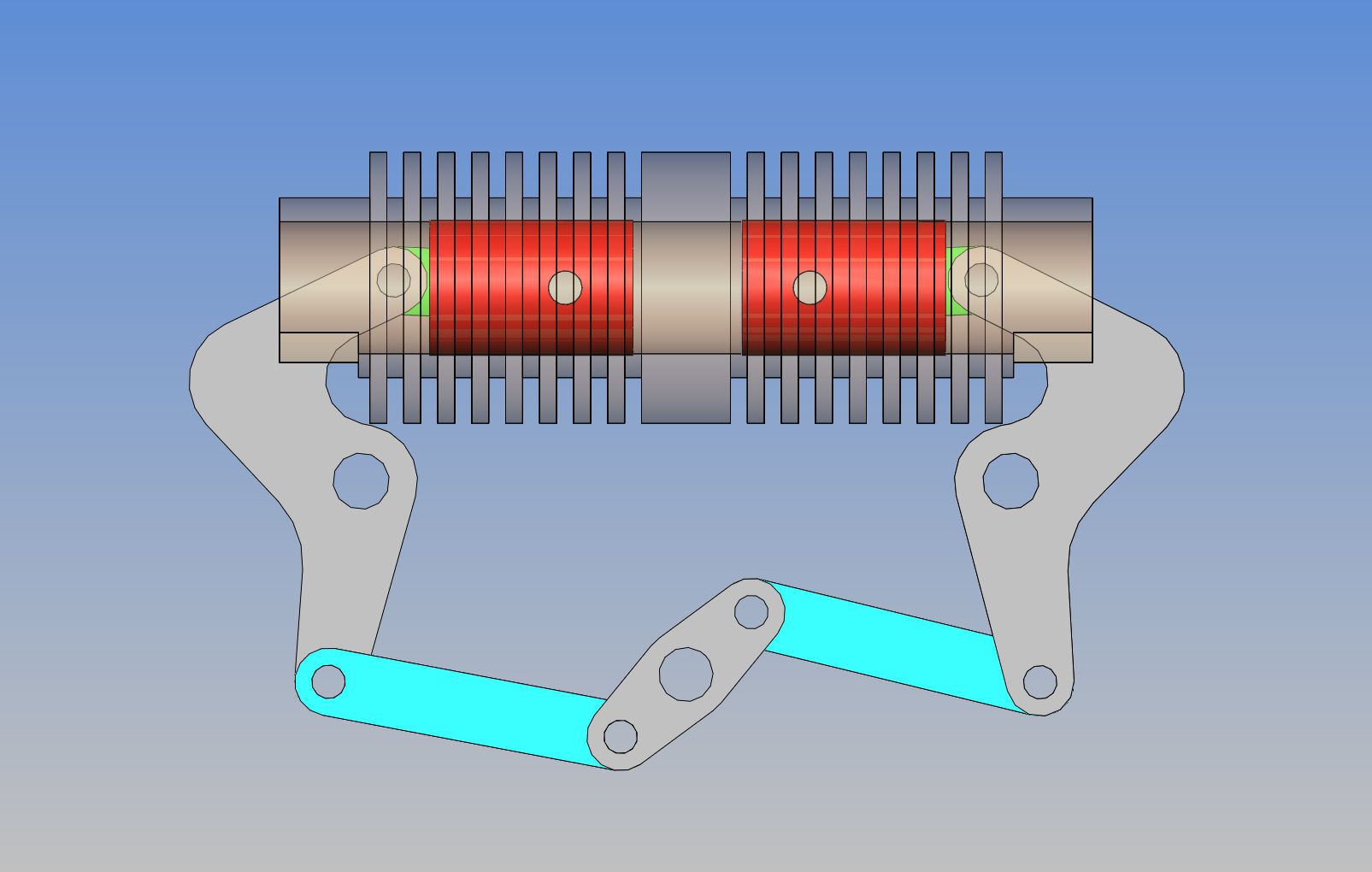

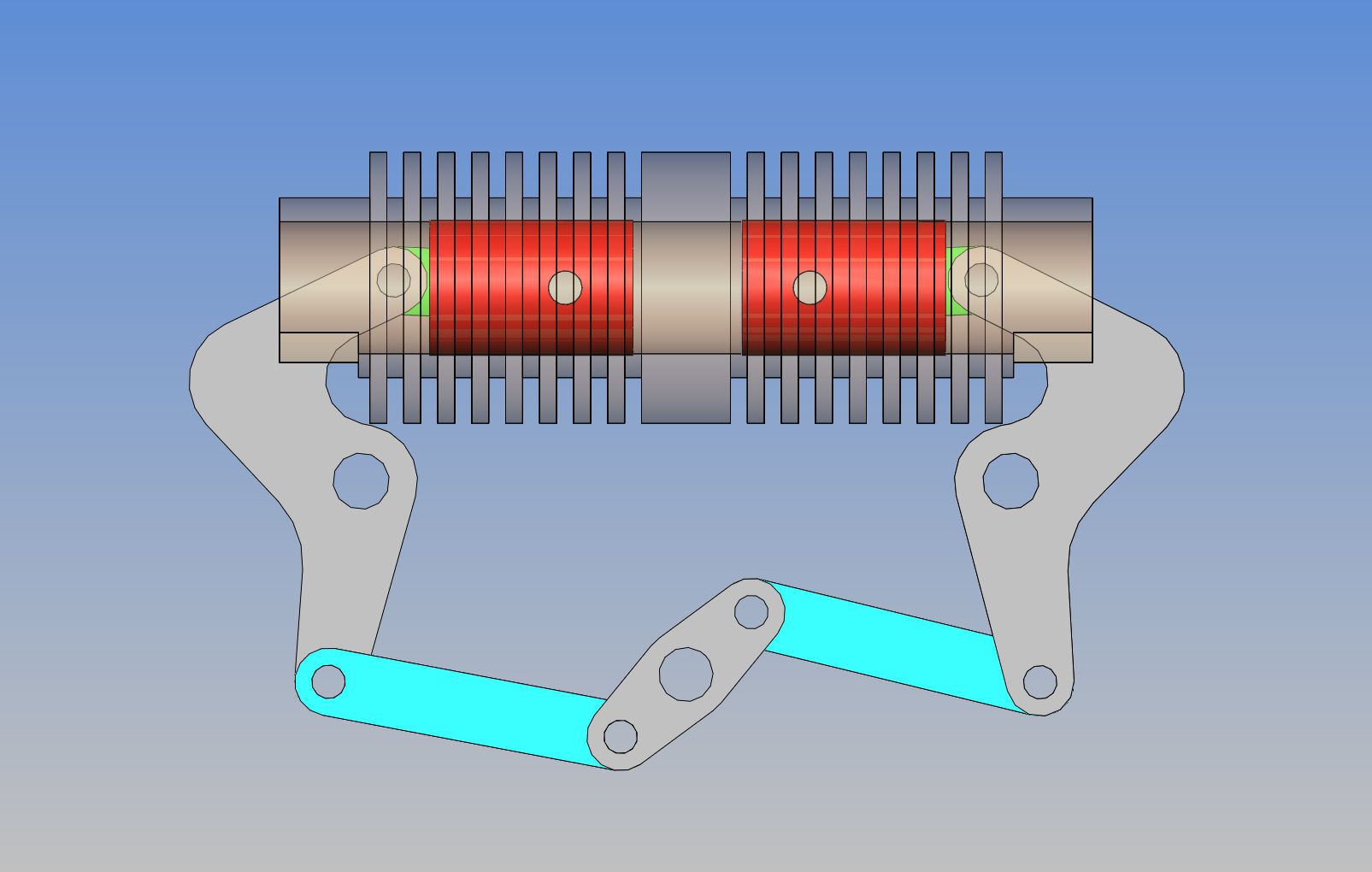

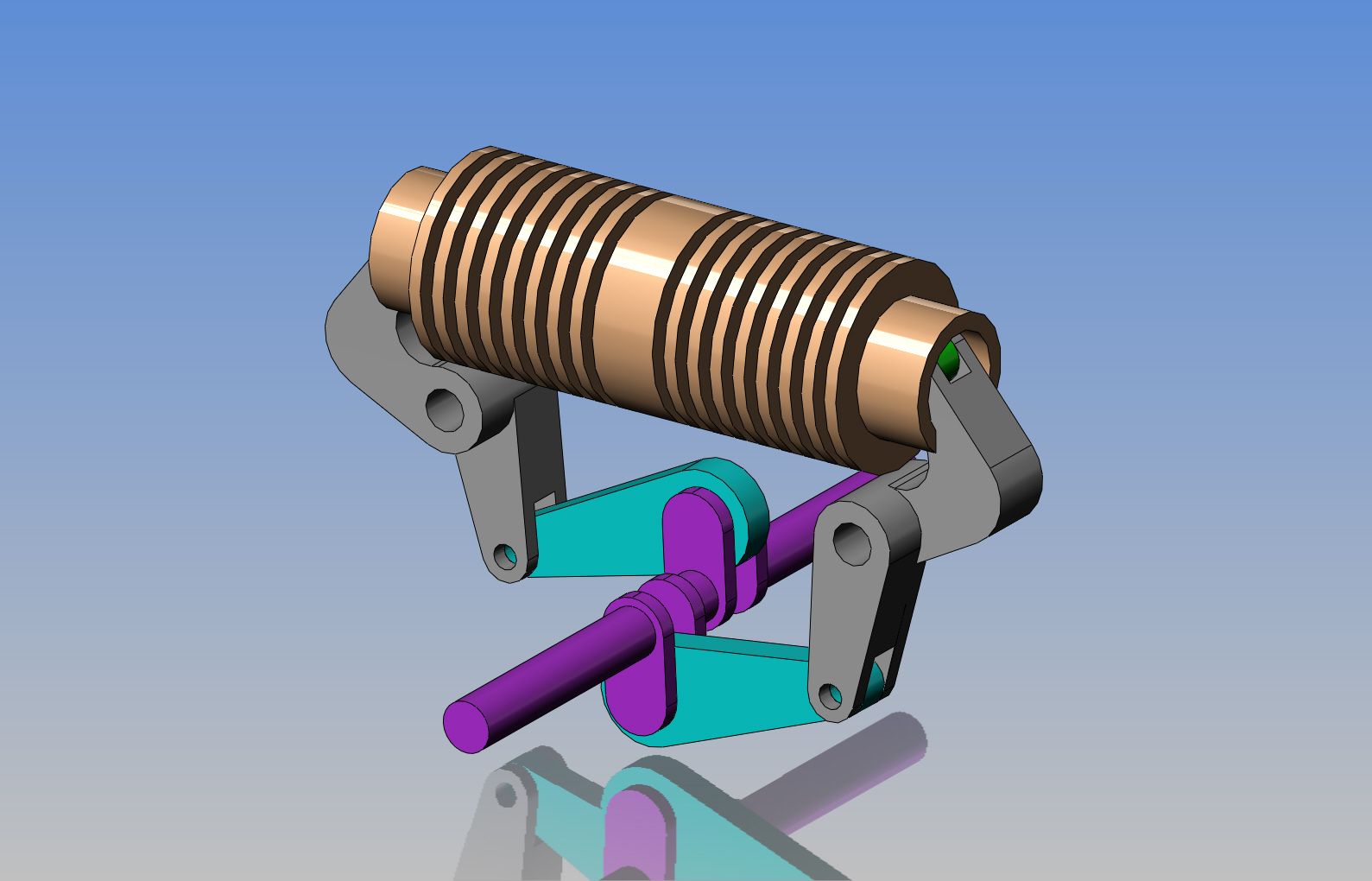

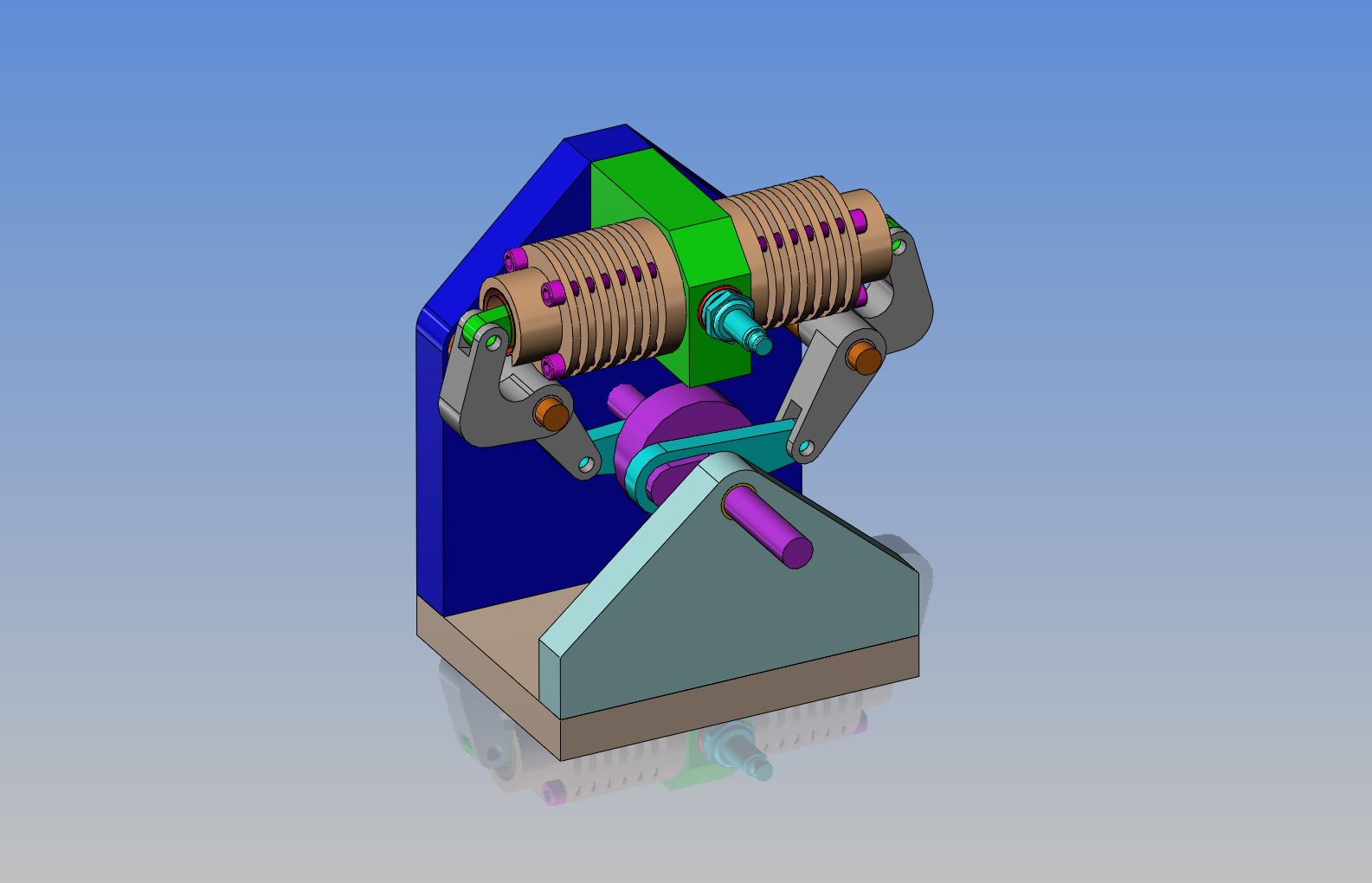

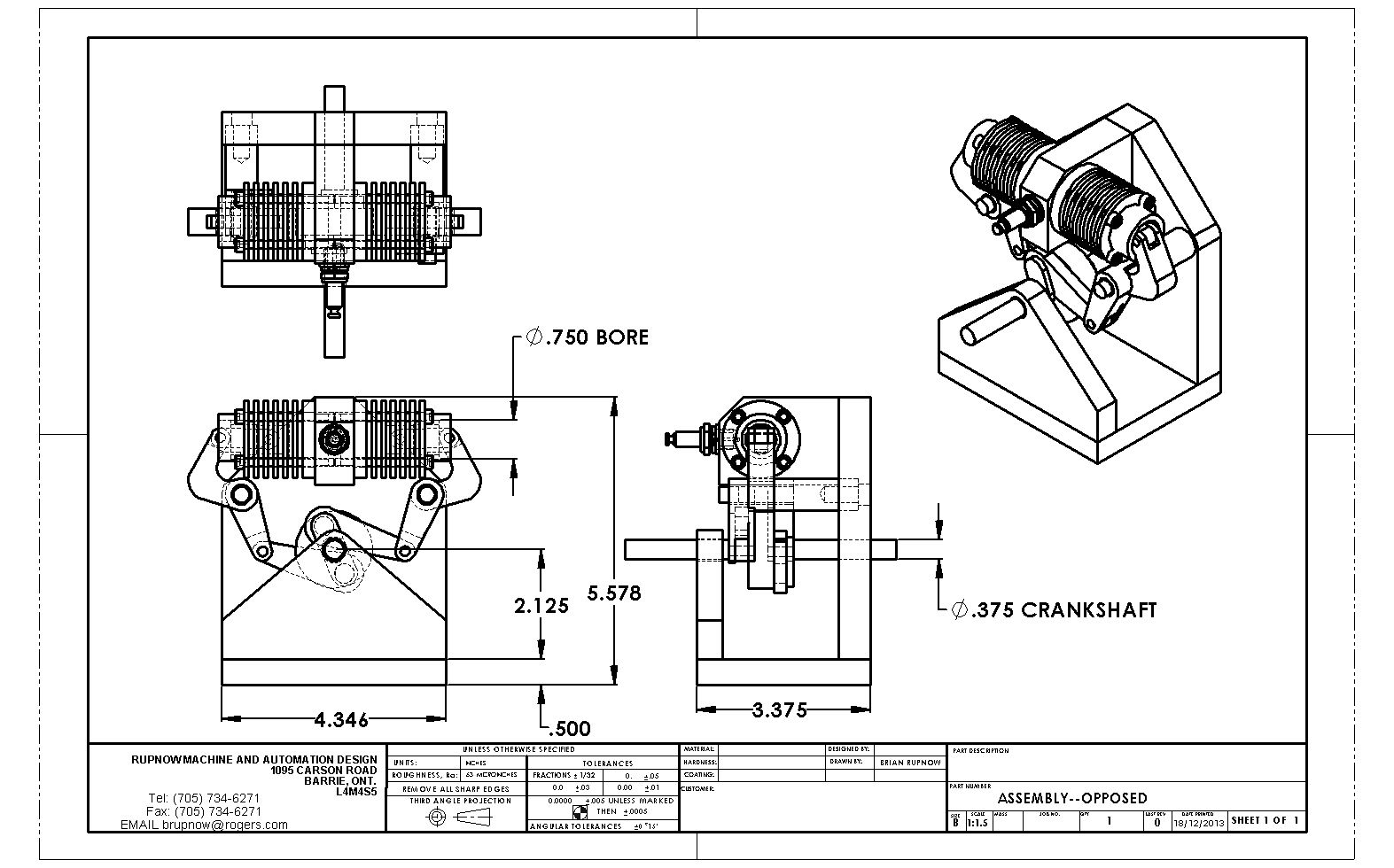

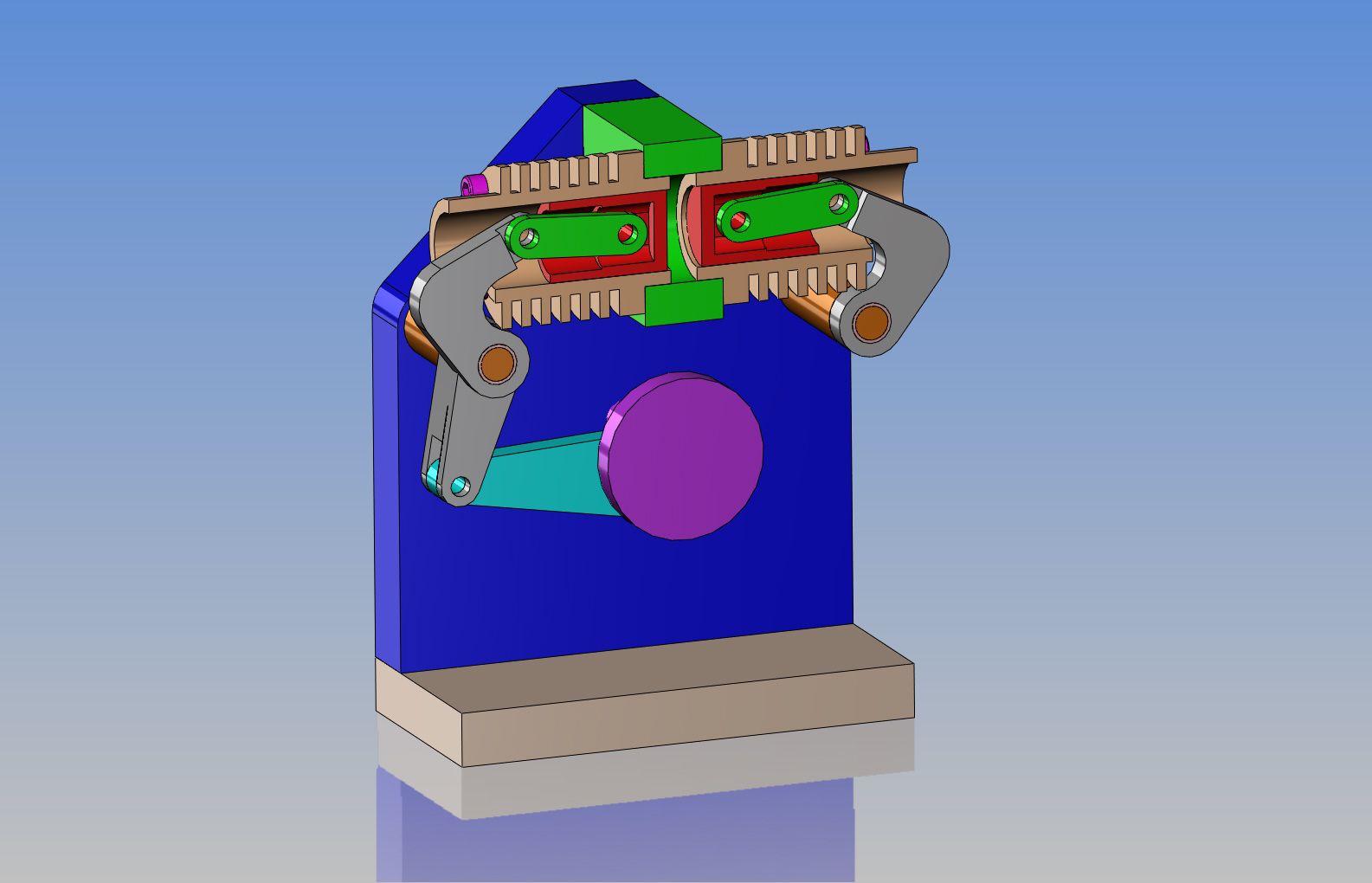

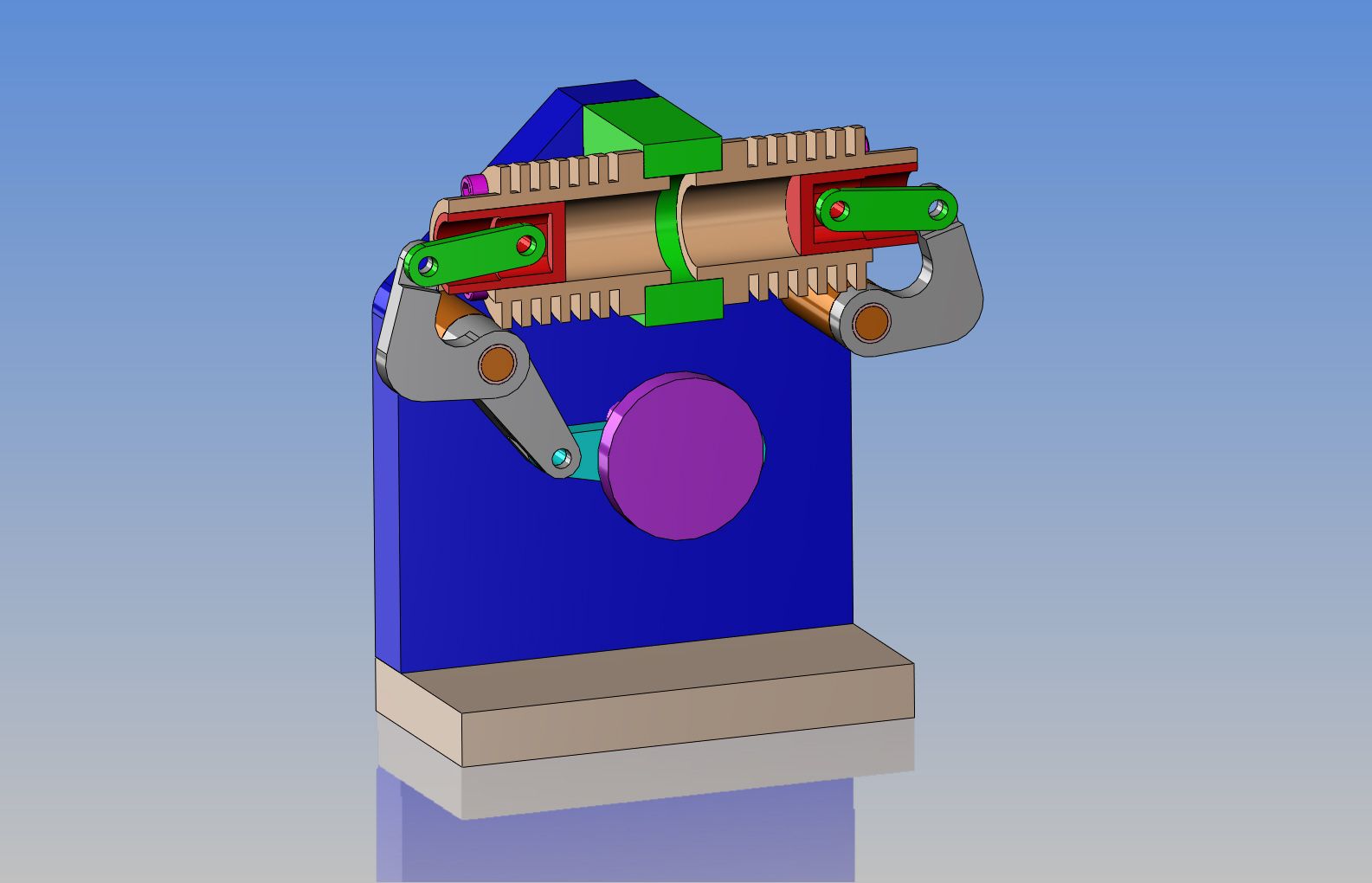

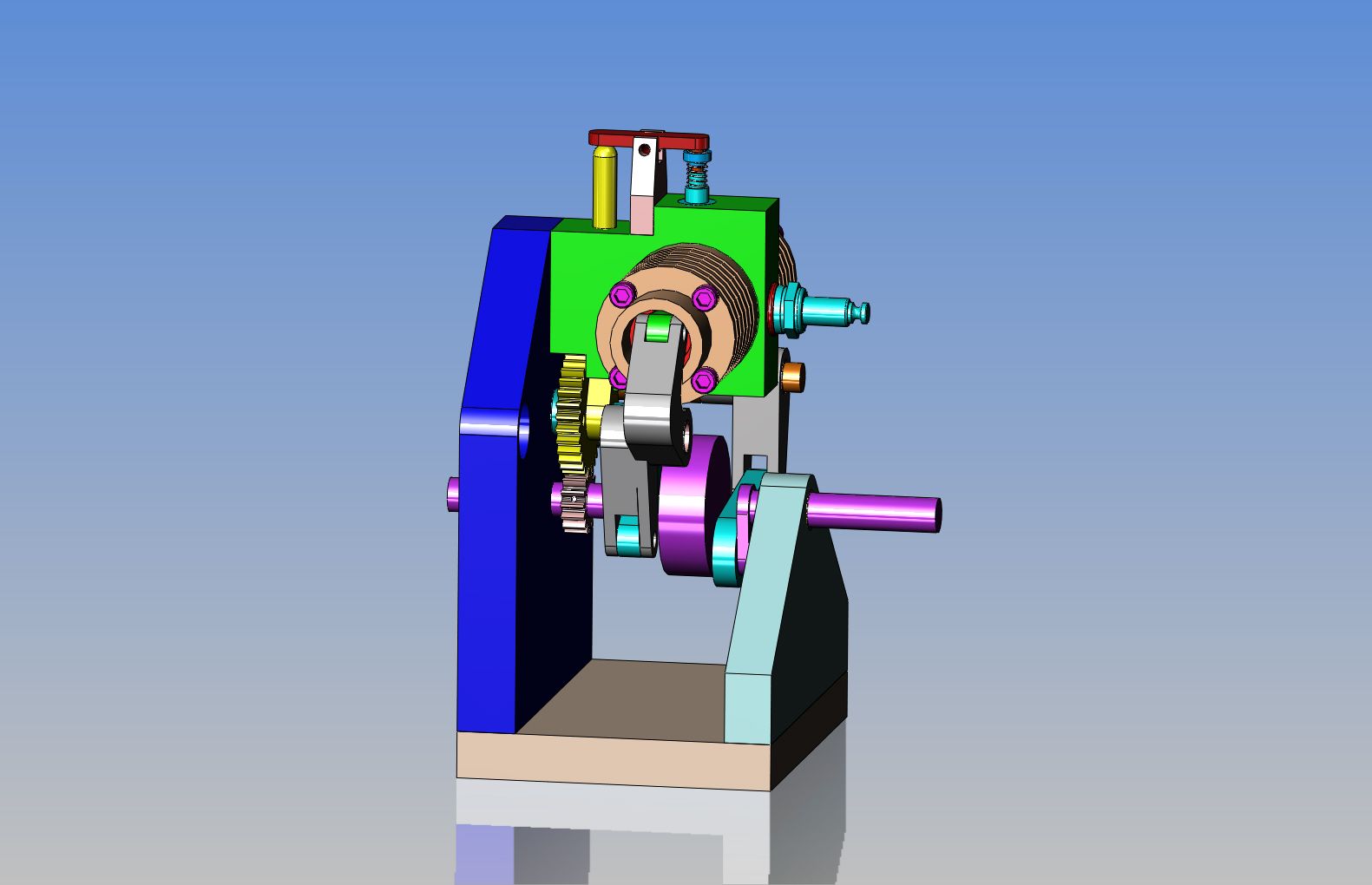

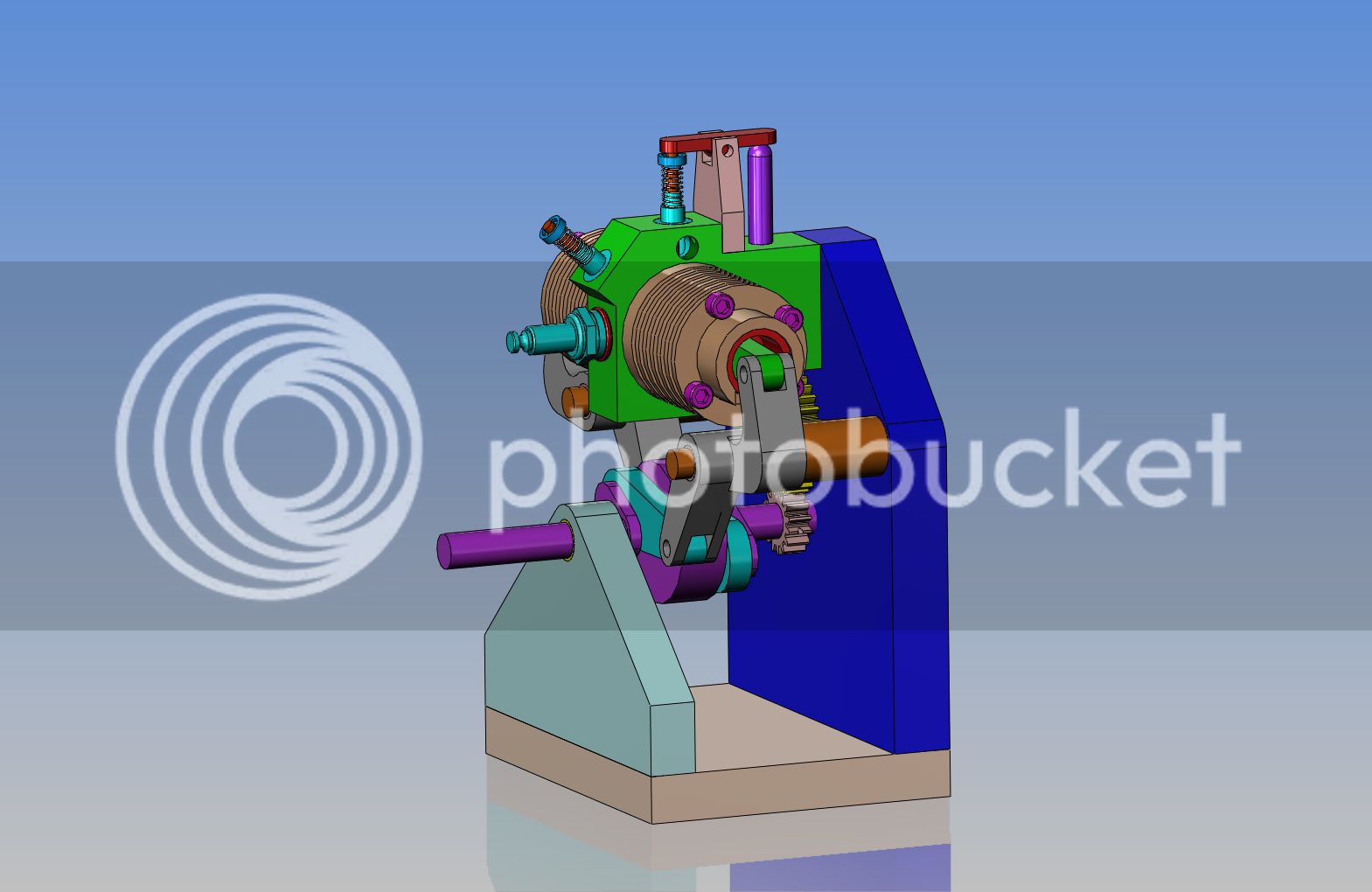

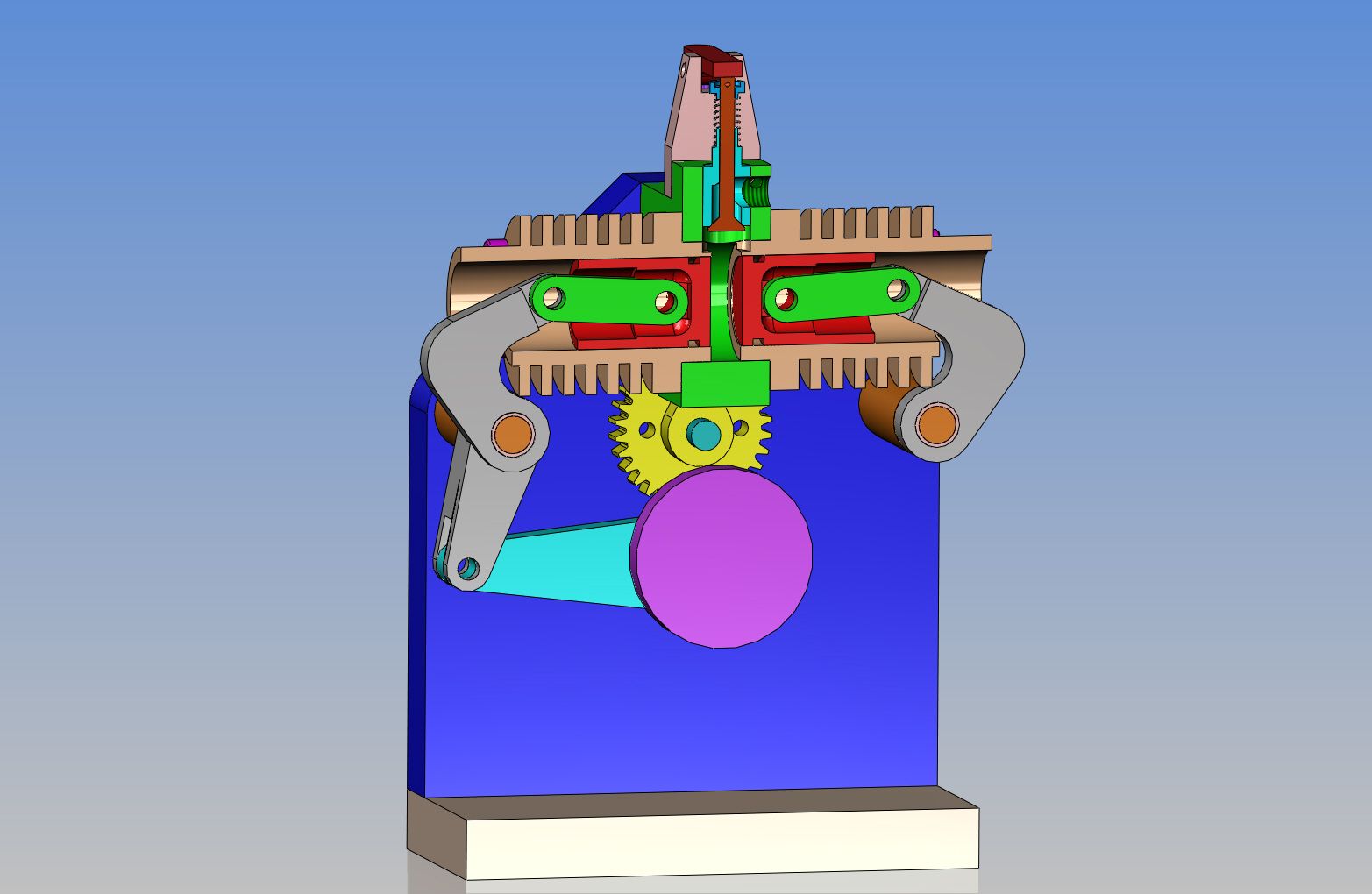

I have been fascinated with a post on another forum about an opposed piston engine. I do not want to plagiarize someone else's post, so I have been surfing around the internet looking at "other" types of opposed piston engines. I found one today, and spent some time doing some preliminary modelling in Solidworks to see what would be involved. I'm not totally sure that this is "do-able" as a model engine, but I thought it was well worth having a look at. This is what I come up with---a 3/4" bore x approximately 1" stroke air cooled single crankshaft engine. I'm not sure if I will go farther with this or not, but it IS interesting.---Brian