hey everyone. i have a little mini lathe that i enjoy modifying. i want to make a quick change gearbox for it at some point to make it more user friendly, and just because!

im wondering if any of you guys have pictures and explanation of how the nicer quick change gearboxes work on big lathes. i have seen pics of the simple ones with two levers and tumbler gears with the sloped detent holes. what i want to make is the type with two knobs that turn into different positions to select the gear. but i have not been able to find out how these kinds work. the reason i want this kind is simply that i like it more than the old school ones like on little atlas machines.

so what is the mechanism that allows a rotating knob to mesh different diameter gears?

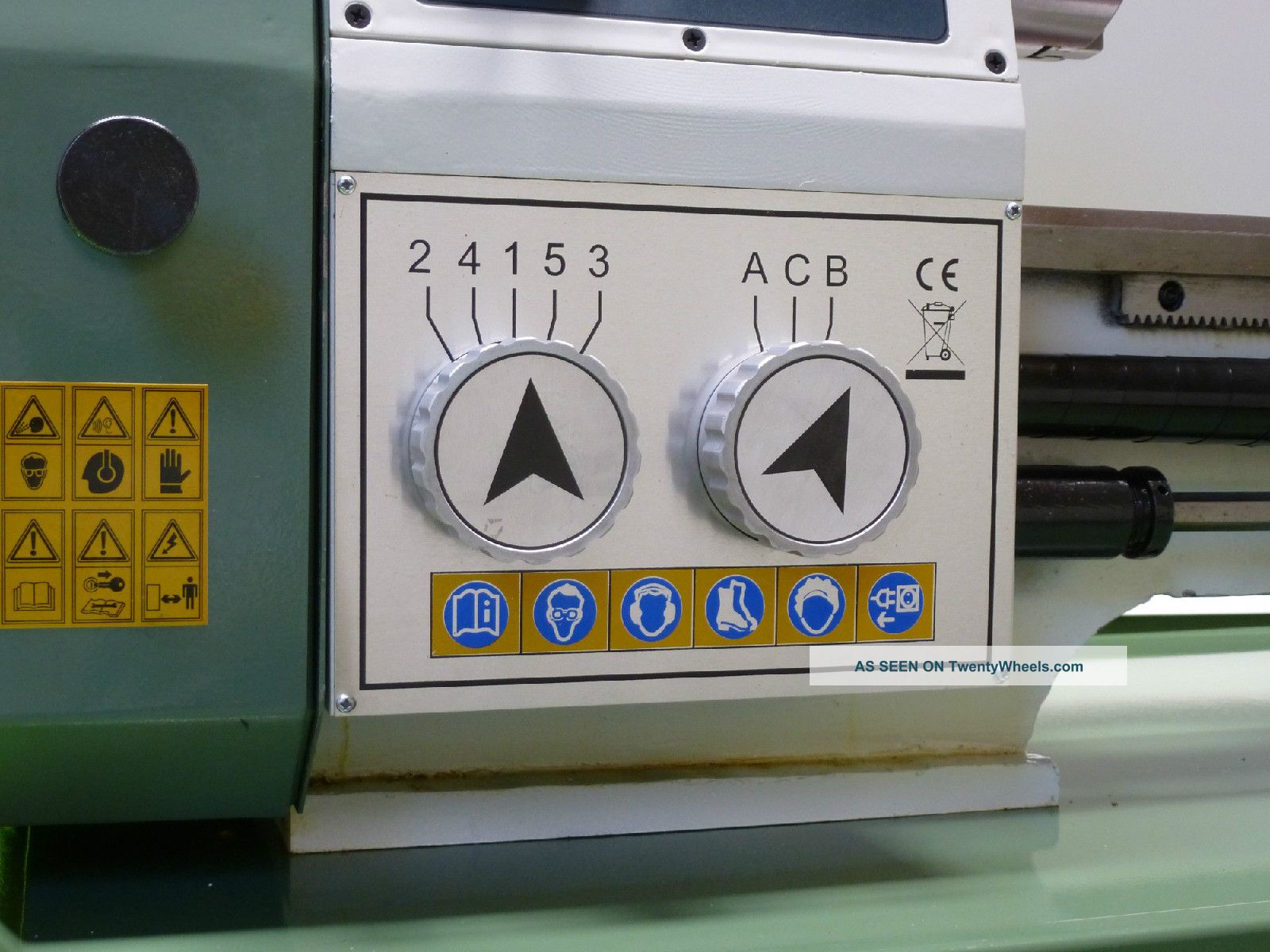

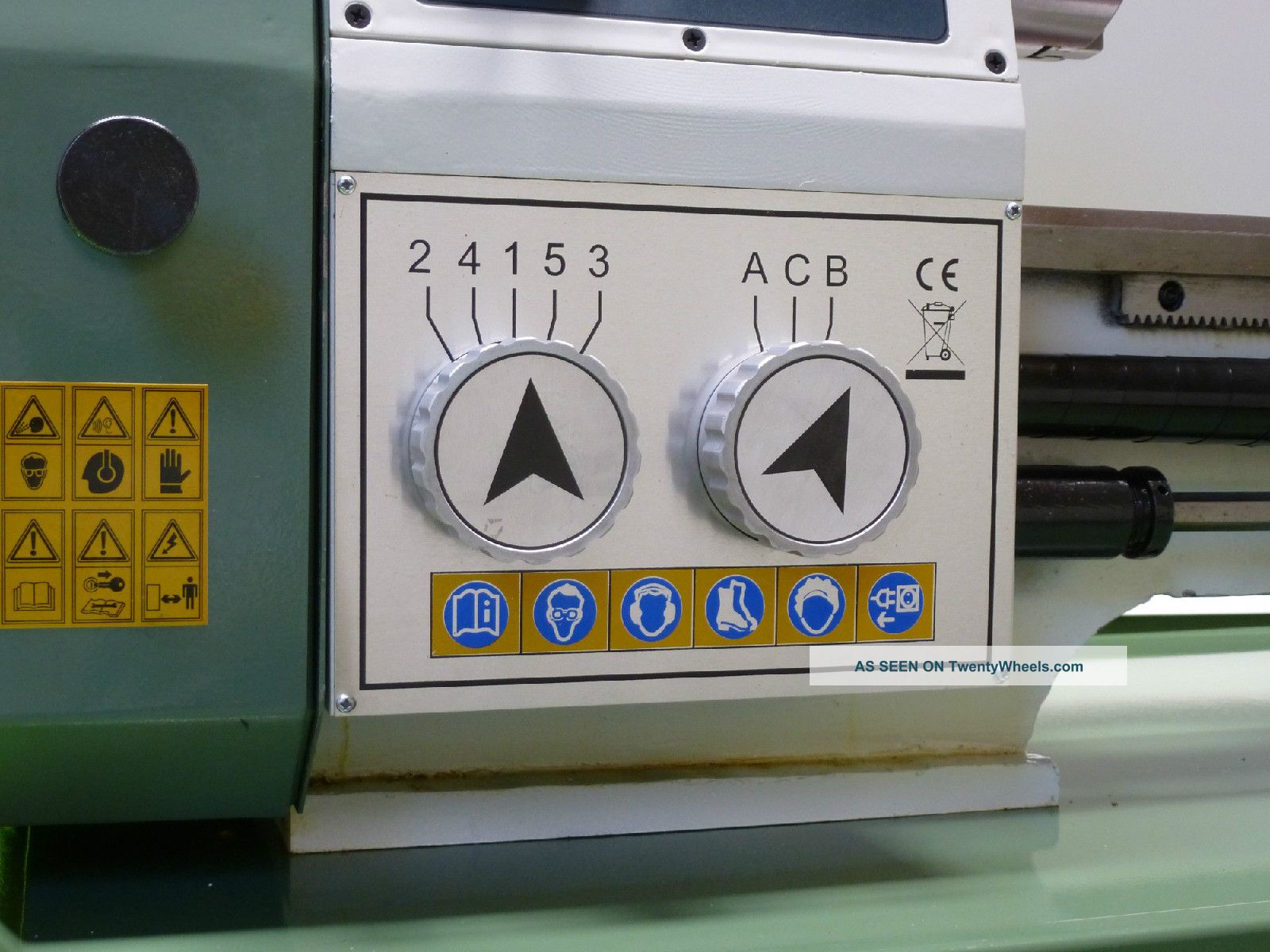

here is the kind i am wondering about.

im wondering if any of you guys have pictures and explanation of how the nicer quick change gearboxes work on big lathes. i have seen pics of the simple ones with two levers and tumbler gears with the sloped detent holes. what i want to make is the type with two knobs that turn into different positions to select the gear. but i have not been able to find out how these kinds work. the reason i want this kind is simply that i like it more than the old school ones like on little atlas machines.

so what is the mechanism that allows a rotating knob to mesh different diameter gears?

here is the kind i am wondering about.