GaryK

Well-Known Member

- Joined

- Mar 19, 2013

- Messages

- 73

- Reaction score

- 80

Your killing me how close you work to your vise jaws by the way! Make you some soft jaws man!

Soft jaws are for wimps!

Seriously, I ALWAYS check for clearance before I ever do anything near the jaws.

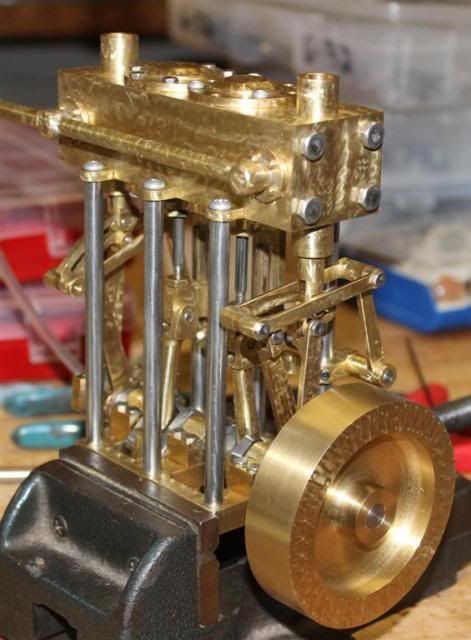

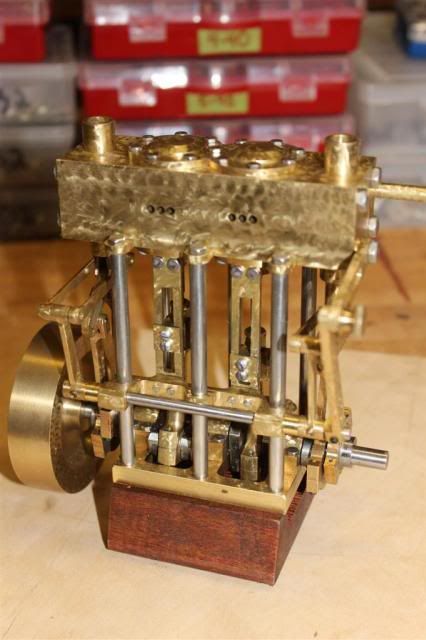

The press together crankshaft doesn't seem to work out like I had hoped so I will be making a new one.

I also got the engine running on one cylinder to test the timing for the eccentrics. I will be making two new of those also. The two will have the setscrew for adjustment.

So things will just take a little longer than I thought.

Gary