jgedde

Well-Known Member

- Joined

- Jan 17, 2013

- Messages

- 214

- Reaction score

- 122

I purchased the plans for the J.E. Howell Farm Boy Hit and Miss engine. The plans are first rate and Mr Howell's design is supurb.

I'm a bit of a Newbie having completed only one other engine: a PM Research #7 Twin Cylinder Steam Engine from their unmachined casting kit.

I'm likely in slightly over my head with the Farm Boy, but it'll be a first rate learning experience for sure.

I started the build with the two flywheels and their split collets. Rather than use cast iron for the flywheels, I used 303 stainless and moved the balance feature inboard the appropriate amount to correct for the added density of the 303.

Here are pics of the finished flywheels and split collets:

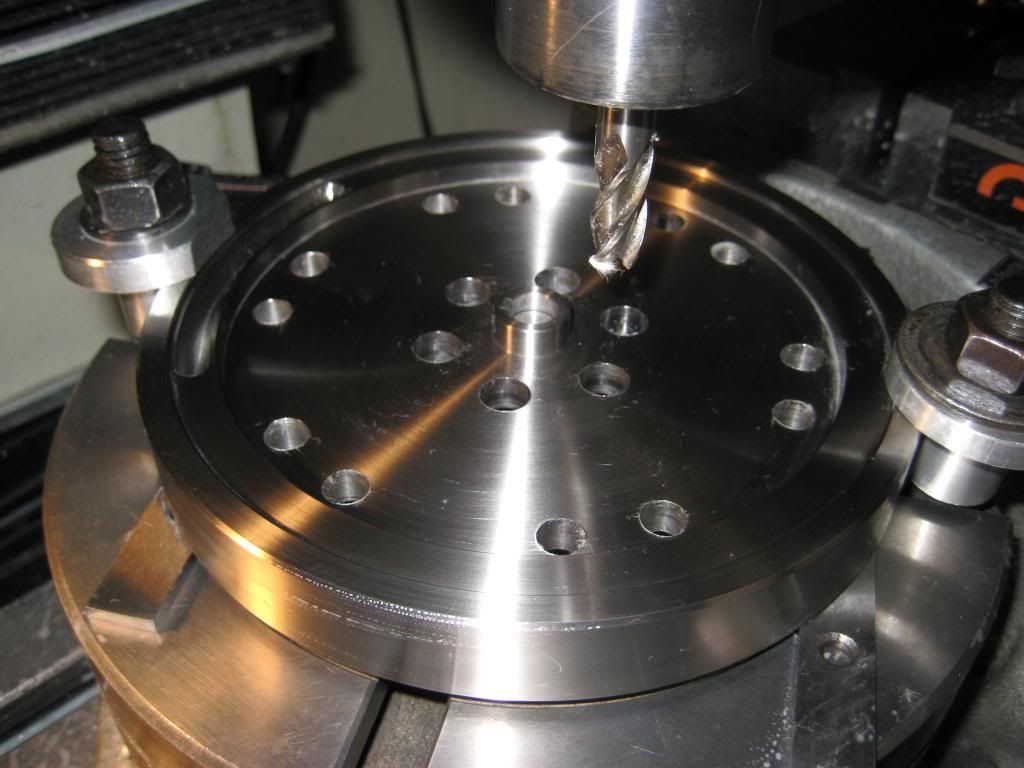

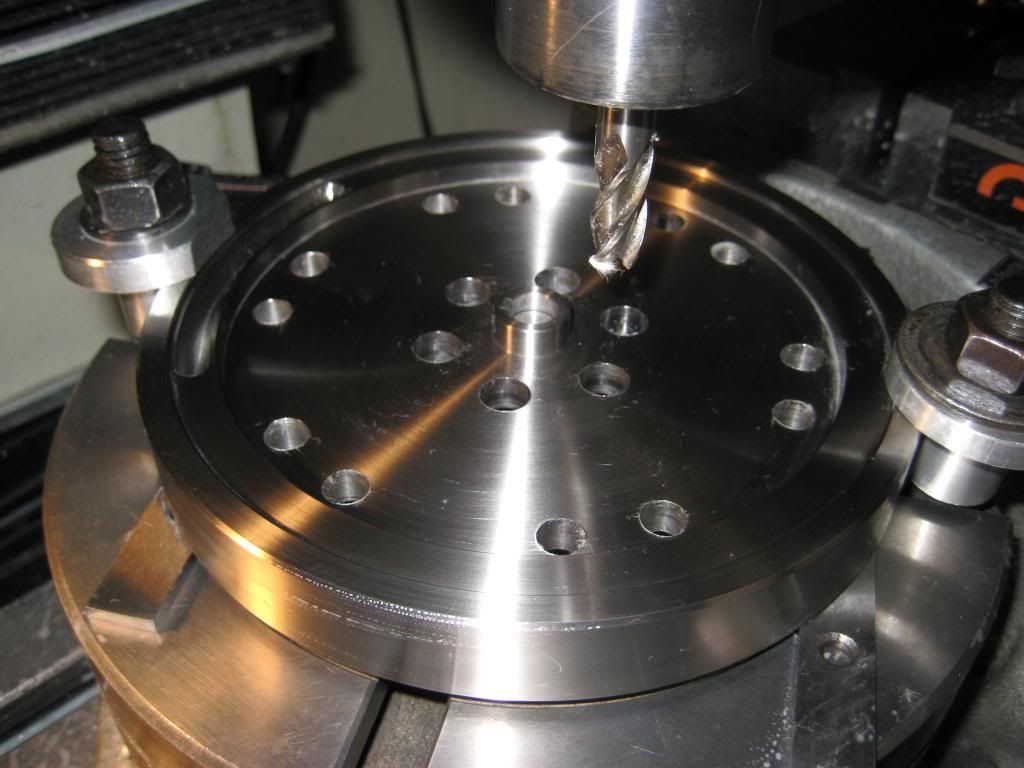

The Machining Process:

I figured I goof beyond recovery machining the spokes, but that didn't happen. I did however drill the three hub screw holes on the wrong bolt circle by 30 thousandsths. Here's the fixed goof... I just threaded and Loctited in some SS screws, then machined them back to the existing surface both on the face of the hub and the tapered ID.

John

I'm a bit of a Newbie having completed only one other engine: a PM Research #7 Twin Cylinder Steam Engine from their unmachined casting kit.

I'm likely in slightly over my head with the Farm Boy, but it'll be a first rate learning experience for sure.

I started the build with the two flywheels and their split collets. Rather than use cast iron for the flywheels, I used 303 stainless and moved the balance feature inboard the appropriate amount to correct for the added density of the 303.

Here are pics of the finished flywheels and split collets:

The Machining Process:

I figured I goof beyond recovery machining the spokes, but that didn't happen. I did however drill the three hub screw holes on the wrong bolt circle by 30 thousandsths. Here's the fixed goof... I just threaded and Loctited in some SS screws, then machined them back to the existing surface both on the face of the hub and the tapered ID.

John