Rob.Barrett

Well-Known Member

- Joined

- Oct 14, 2009

- Messages

- 52

- Reaction score

- 109

Hi All,

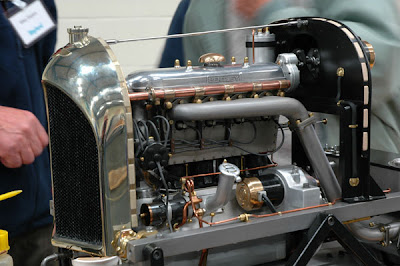

Progress so far on the cylinder head. It's made from two bits (to give a water jacket) which are dowelled together with 18 dowels.

Rob

Progress so far on the cylinder head. It's made from two bits (to give a water jacket) which are dowelled together with 18 dowels.

Rob