vascon2196

Well-Known Member

- Joined

- Oct 2, 2009

- Messages

- 1,026

- Reaction score

- 312

Hello everyone,

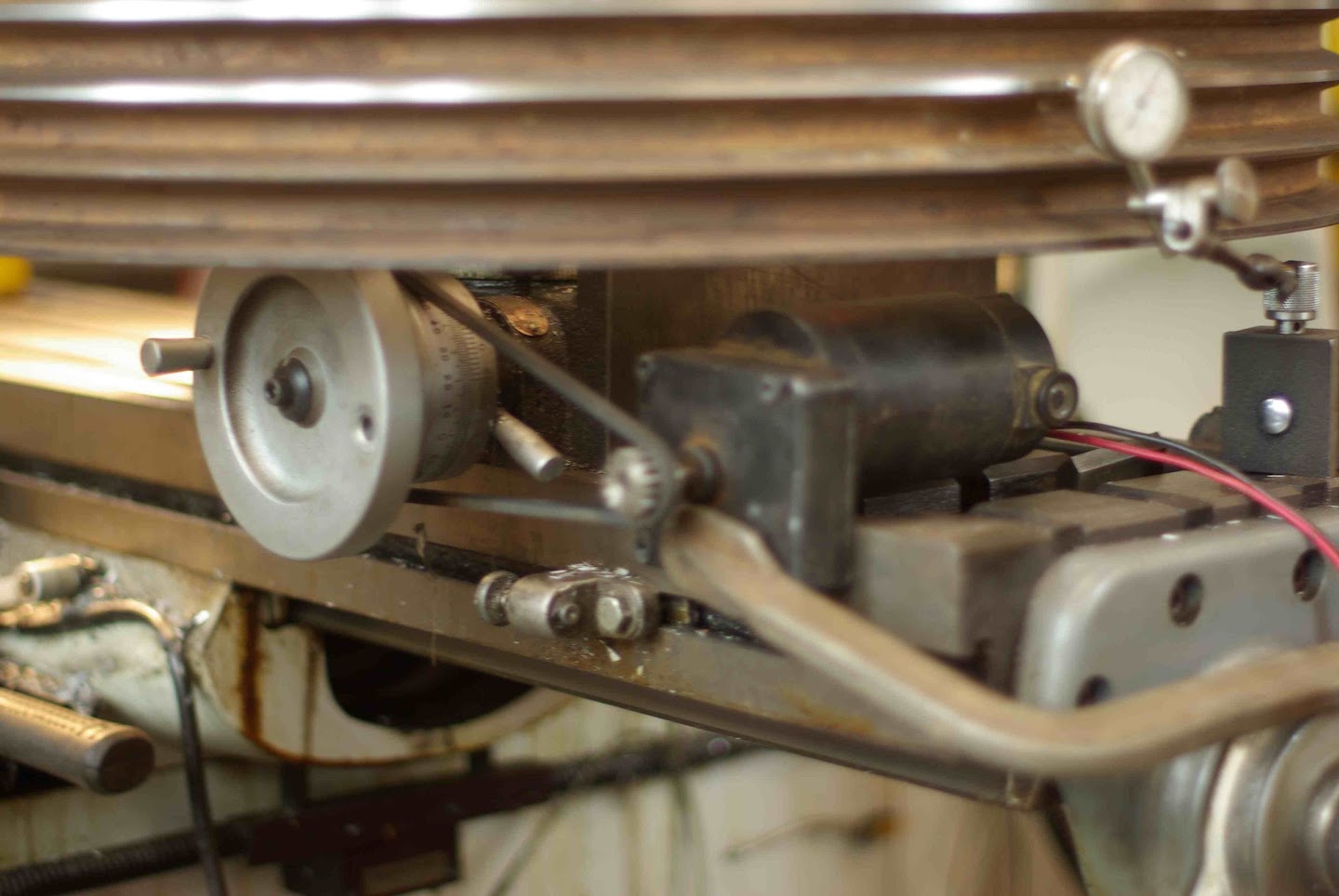

I have been looking for a shop to help out my students with a project we are working on to machine an 18" diameter flywheel. The flywheel is for Henry Ford's Quadricycle.

Would anyone here be interested in this? Do you know anyone in the Massachusetts/Rhode Island area that could help?

There are about 125 parts to this car and this is the only one we cannot do ourselves.

Thanks!

I have been looking for a shop to help out my students with a project we are working on to machine an 18" diameter flywheel. The flywheel is for Henry Ford's Quadricycle.

Would anyone here be interested in this? Do you know anyone in the Massachusetts/Rhode Island area that could help?

There are about 125 parts to this car and this is the only one we cannot do ourselves.

Thanks!