- Joined

- Jul 16, 2007

- Messages

- 2,975

- Reaction score

- 1,043

Hi Keith,

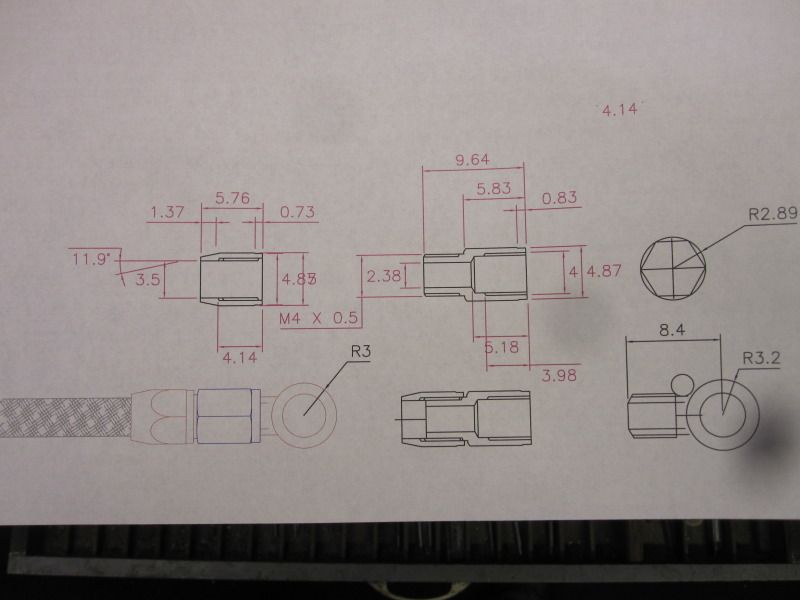

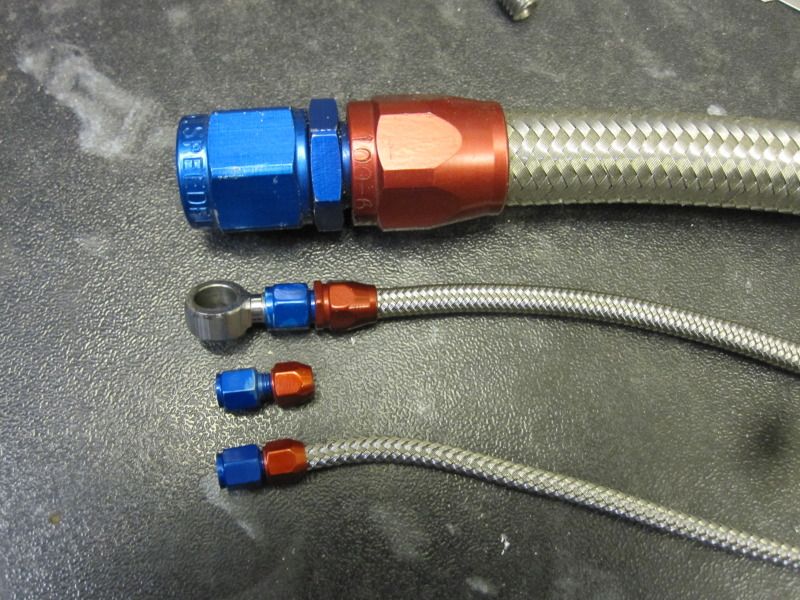

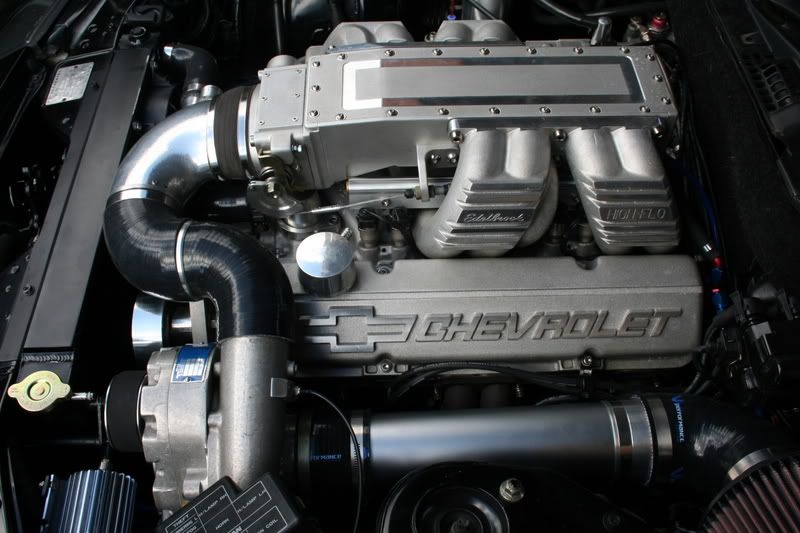

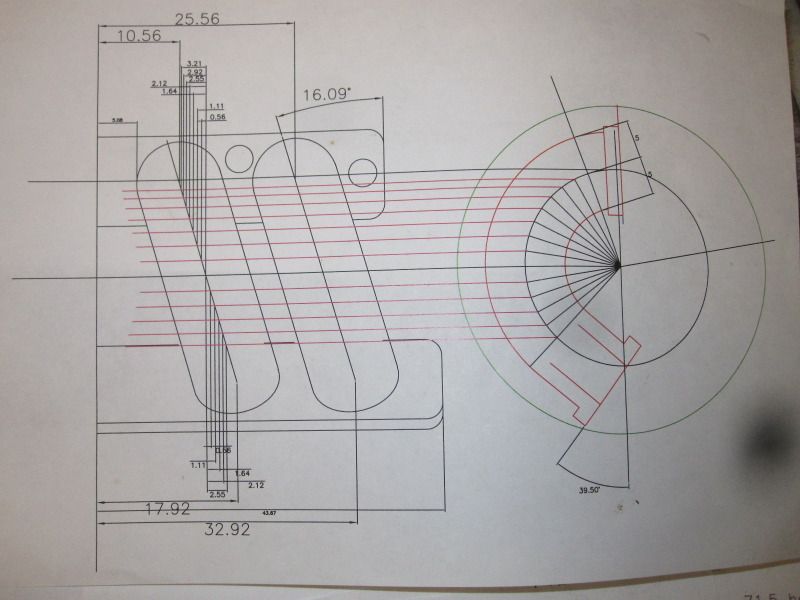

Incredible work on your engine. Your detailing is amazing. I really like those mini AN fittings. I sure could use something like that for the radial I'm building. Do you have a source for them or are they home made? Even if they're home made what are you using for the braided line?

gbritnell

Incredible work on your engine. Your detailing is amazing. I really like those mini AN fittings. I sure could use something like that for the radial I'm building. Do you have a source for them or are they home made? Even if they're home made what are you using for the braided line?

gbritnell