Holt

Well-Known Member

- Joined

- Oct 14, 2010

- Messages

- 164

- Reaction score

- 4

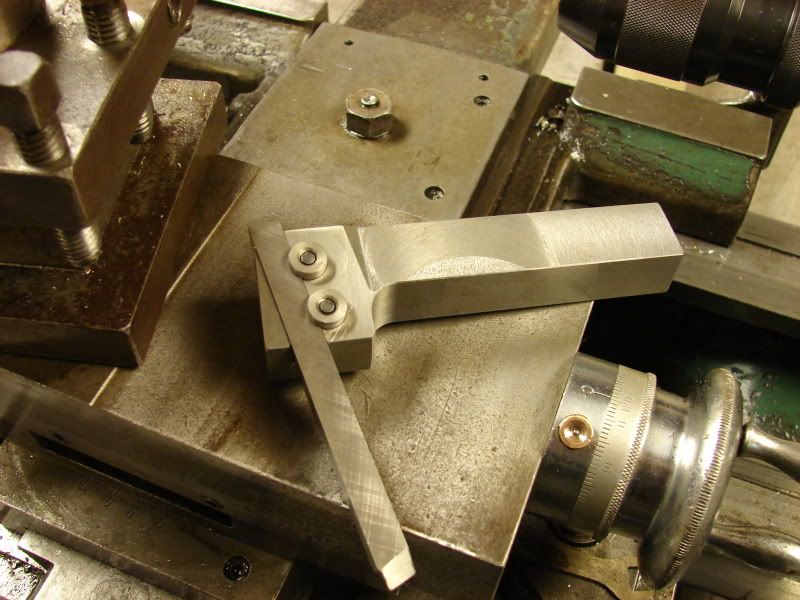

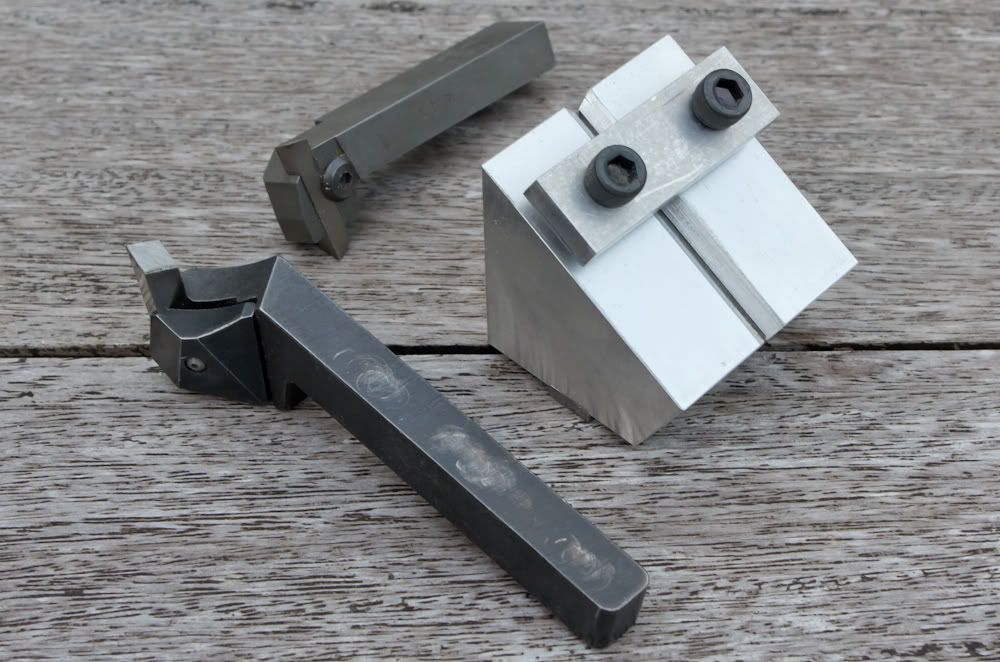

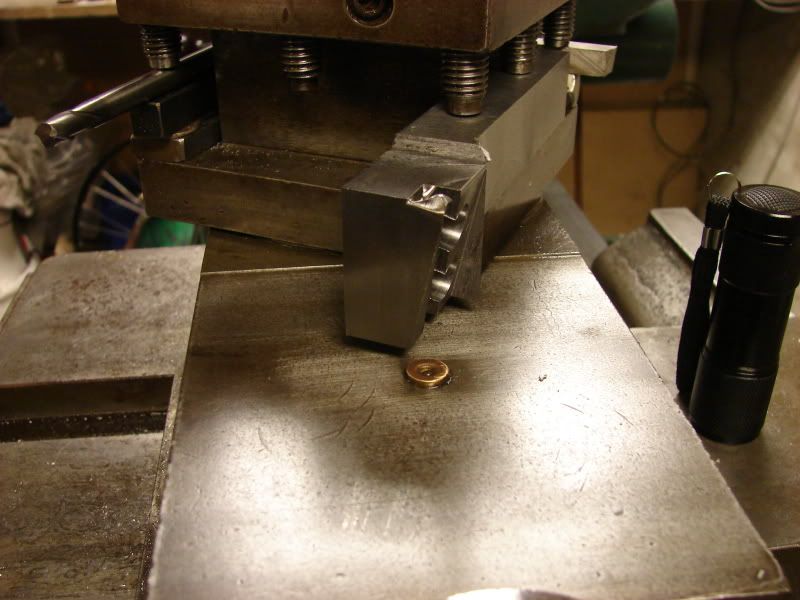

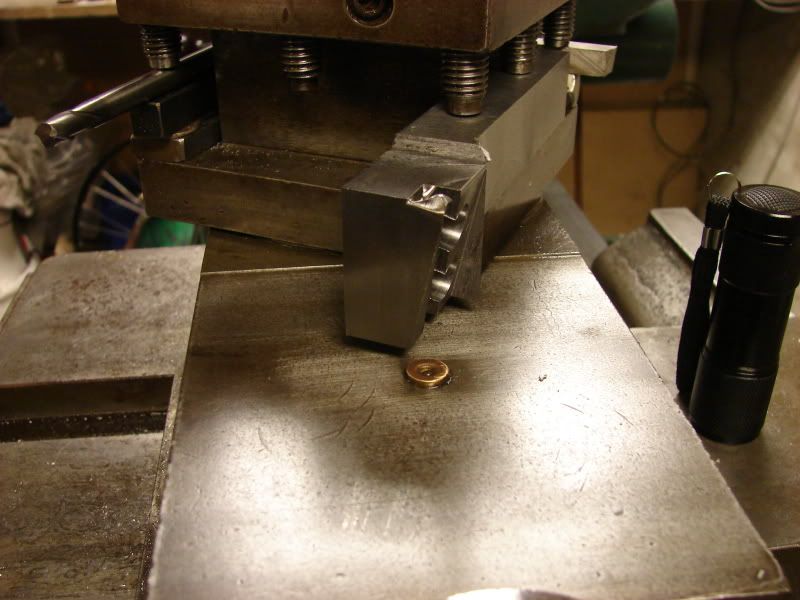

After reading so much good about the tangential toolholder i decided that should be the first "real" tool for my Colchester.

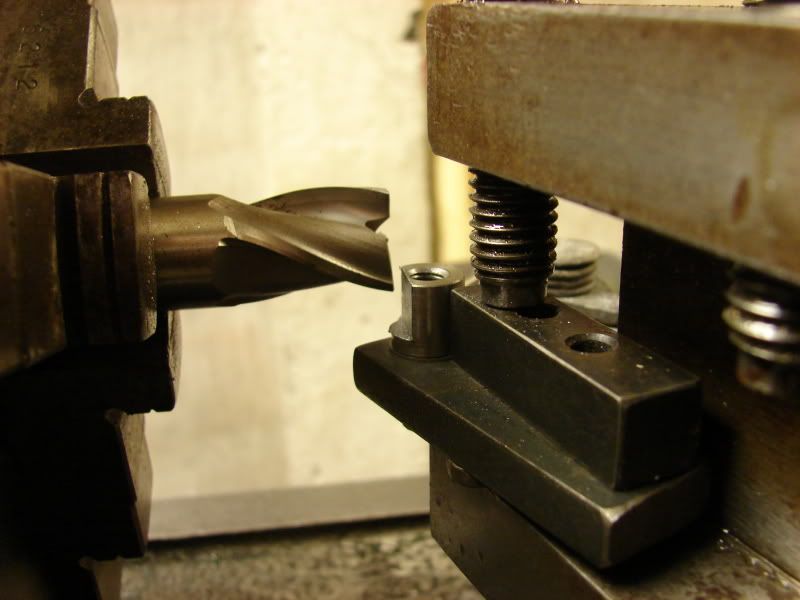

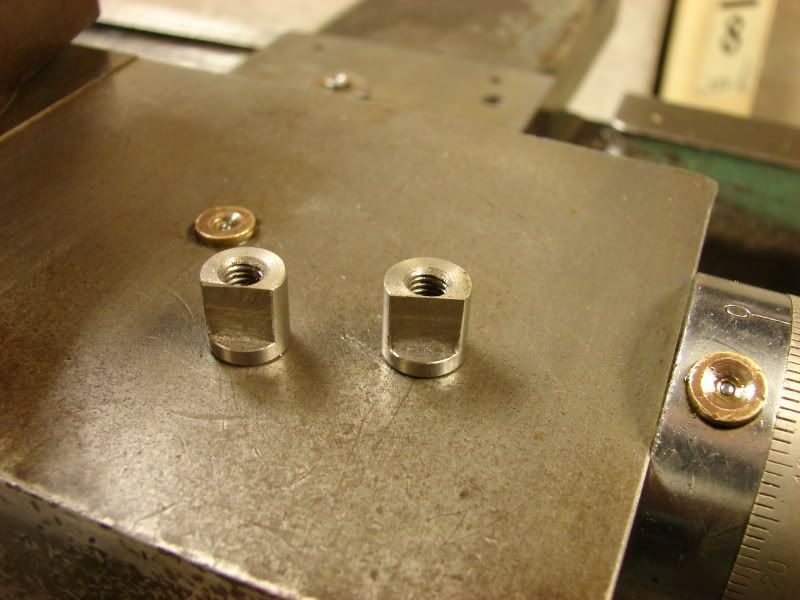

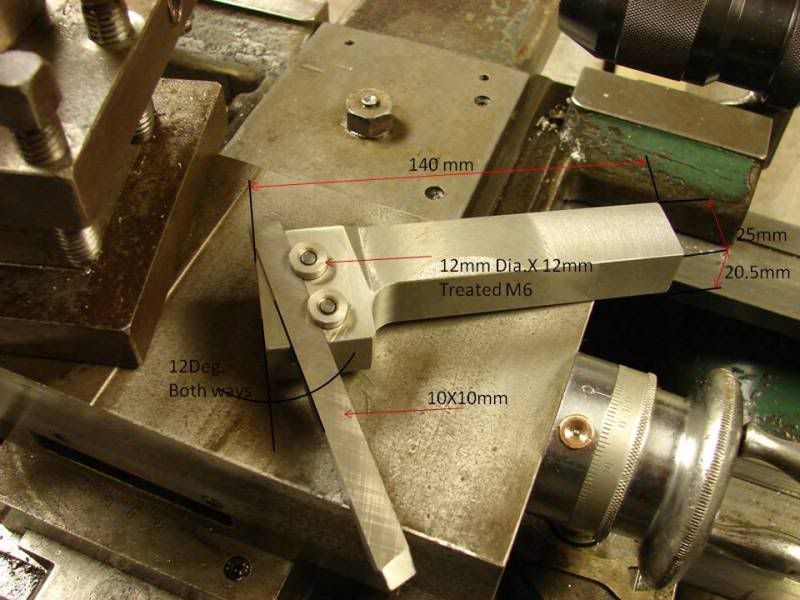

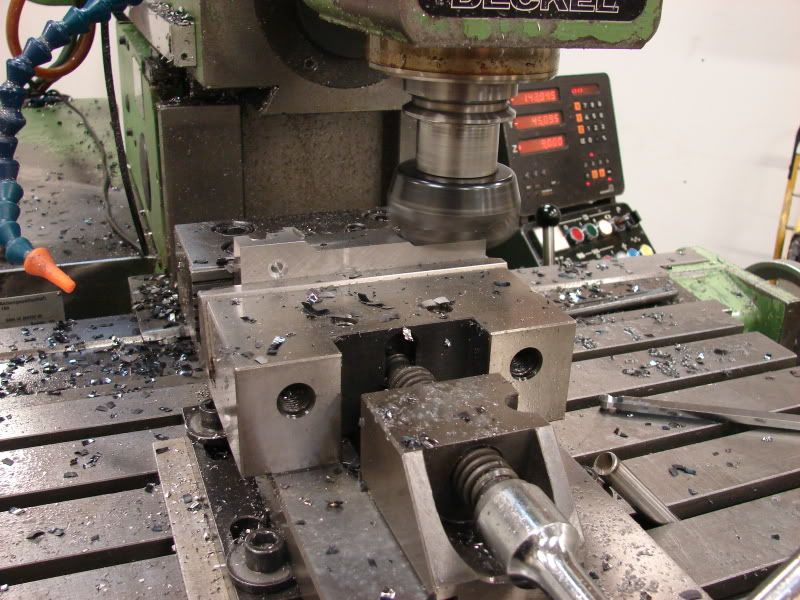

I started with a piece of unknown tool steel 25 X 43 X 140 mm

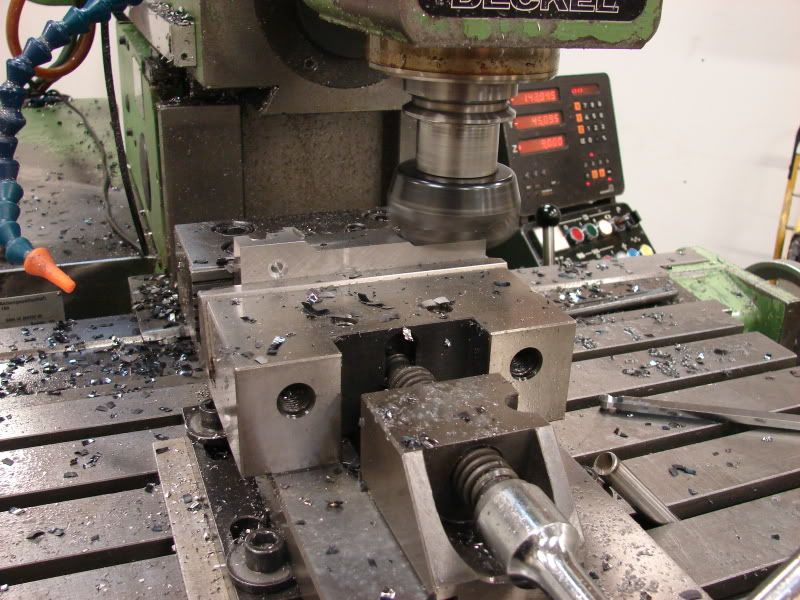

I couldn't find the angle base, so i decided to try the magnetic sinus plane, a bit scary, but with light cuts it went well.

Suddenly time ran out (typical when you are having a good time ) I had to collect my son from sax practice.

) I had to collect my son from sax practice.

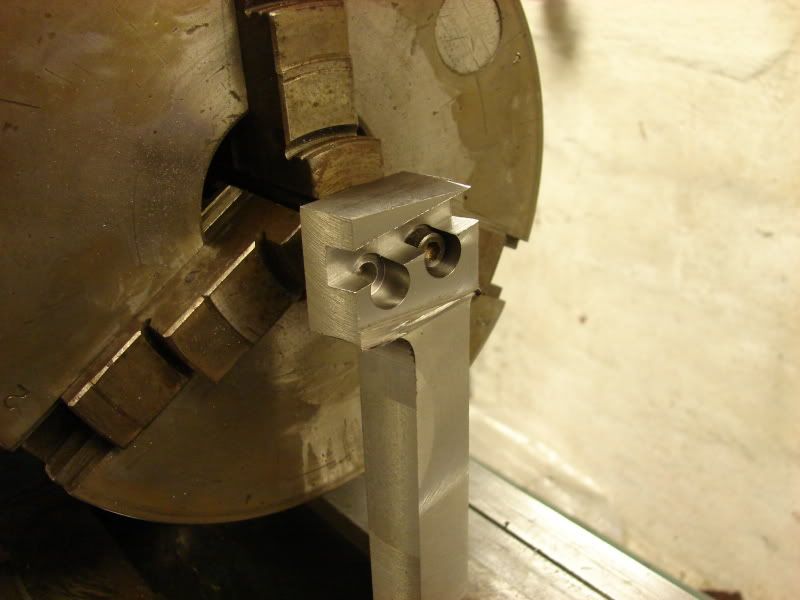

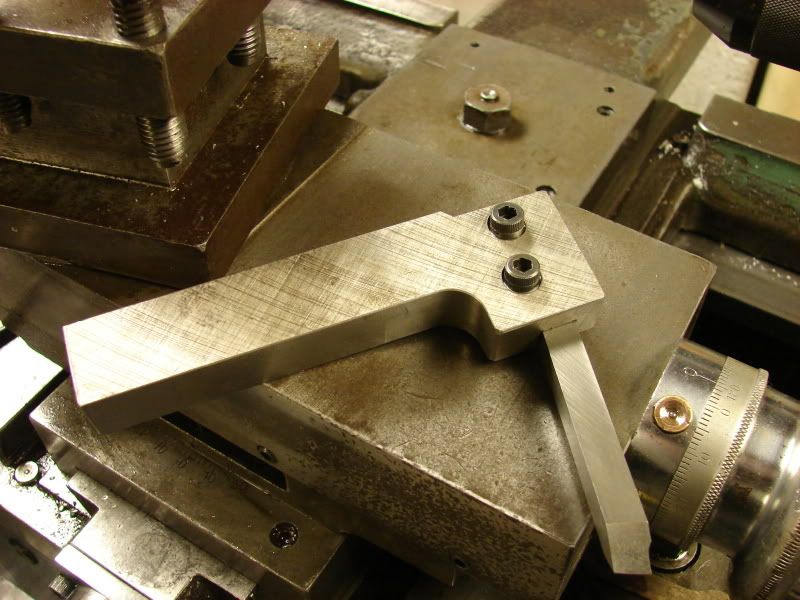

I didn't have time for the last finishing touch, not even for deburring, but at home i made a trial fit in the lathe.

Well, next Wednesday there is 3 hours to kill again, i would think that should be more than enough to finish it ;D

Holt

I started with a piece of unknown tool steel 25 X 43 X 140 mm

I couldn't find the angle base, so i decided to try the magnetic sinus plane, a bit scary, but with light cuts it went well.

Suddenly time ran out (typical when you are having a good time

I didn't have time for the last finishing touch, not even for deburring, but at home i made a trial fit in the lathe.

Well, next Wednesday there is 3 hours to kill again, i would think that should be more than enough to finish it ;D

Holt