My goal was to be in steam 2 years from start, so that would be November this year. I have slowed down a bit lately as other things take up time once the weather turns nicer. I don't have to everything done to steam up the first time. So the cab, boiler jacket, smokebox cover, sand dome, bell, light, handrails, and whistle are optional to run on the track. That said, I want to finish/install everything that would require a lot of disassembly to add.

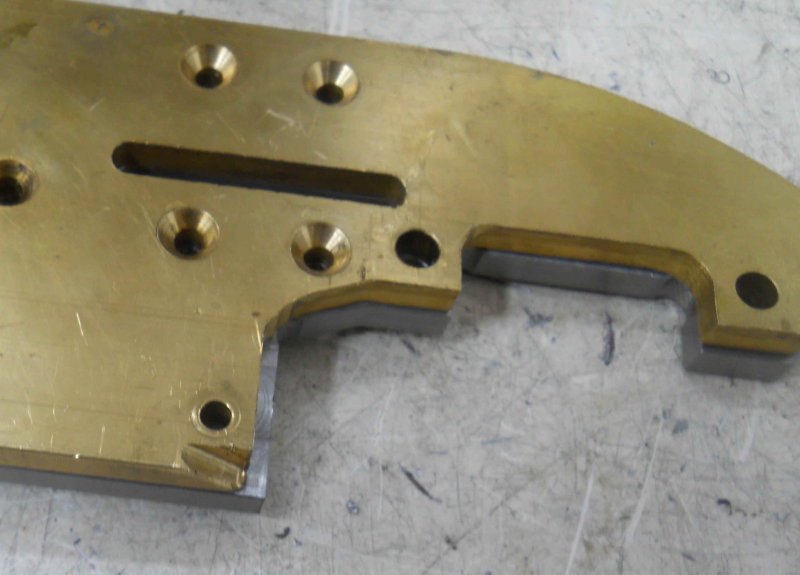

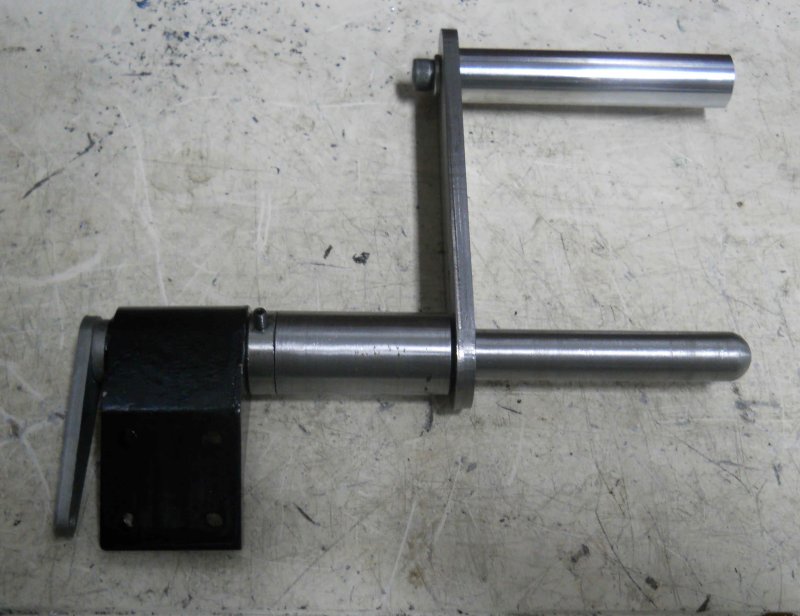

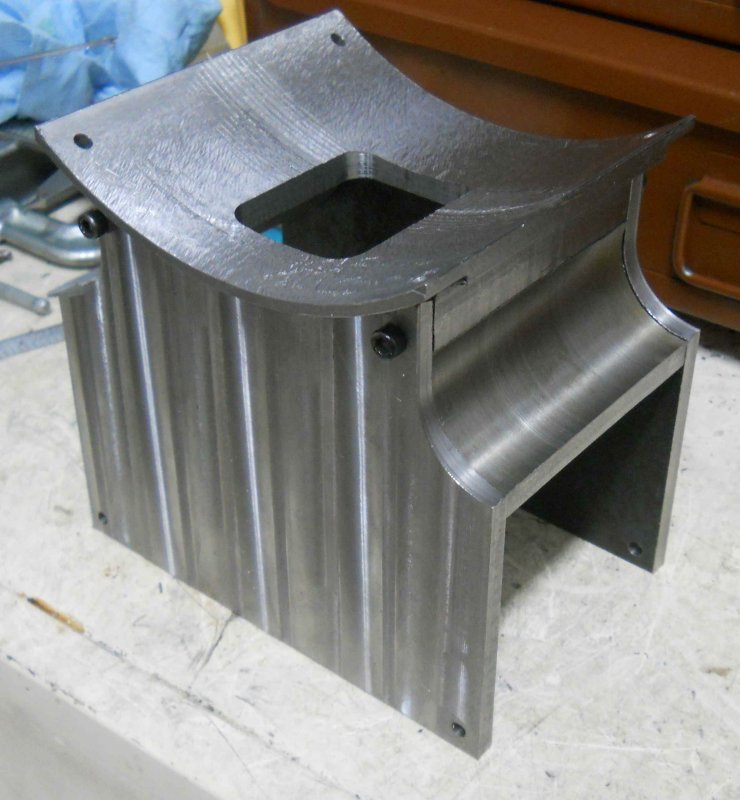

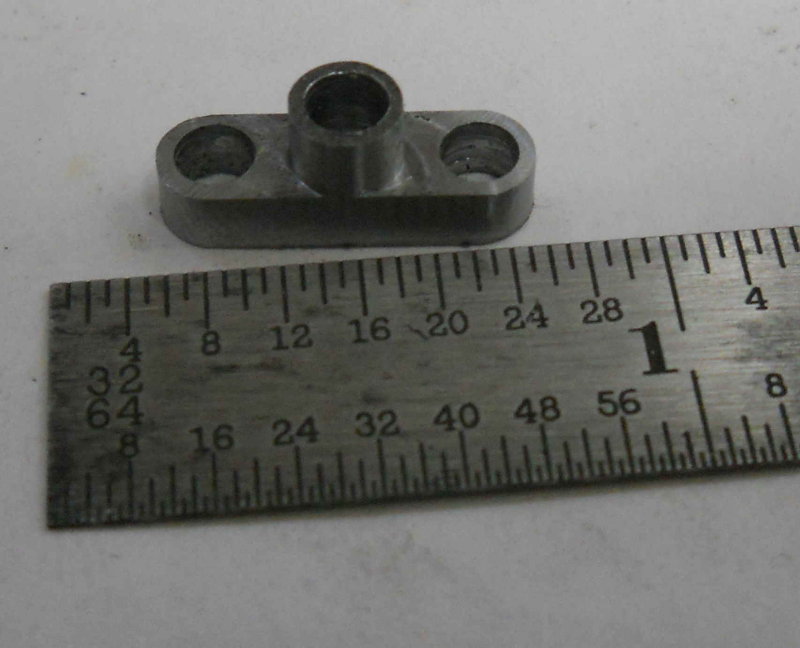

I got the 1/8" HRS for the bottom and front side of the ash pan. Milled them to size and MIG welded them together (if you call my booger welds "welding). Then attached the sides with JB weld. The second side is curing now. Once set I'll paint it and take a pic. This isn't a visible part so I can't say I took a lot of care making it look good. Given that the pan attaches to the boiler firebox support, removing it once the boiler is in place would be a bit of a PITA. Kozo's design would require removing the supports, so I made a small modification. First, I tapped the pin holes in the supports 1/4-20, and then bought a pair of hex head 1/4-20x1/2" bolts. Next I took a piece of 1/2" aluminum rod 1/2" long and drilled/tapped it on the lathe. After screwing the bolt into this jig, I was able to turn the end 1/4" of threads down to 1/8":

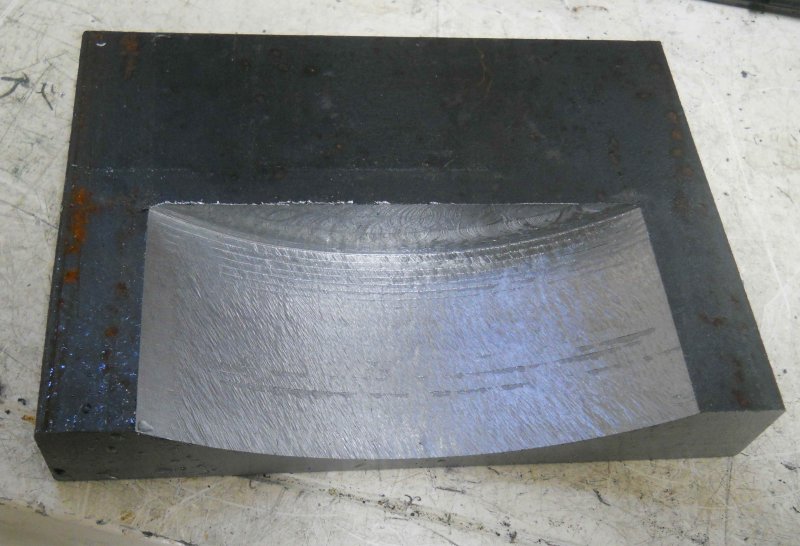

Here's the result:

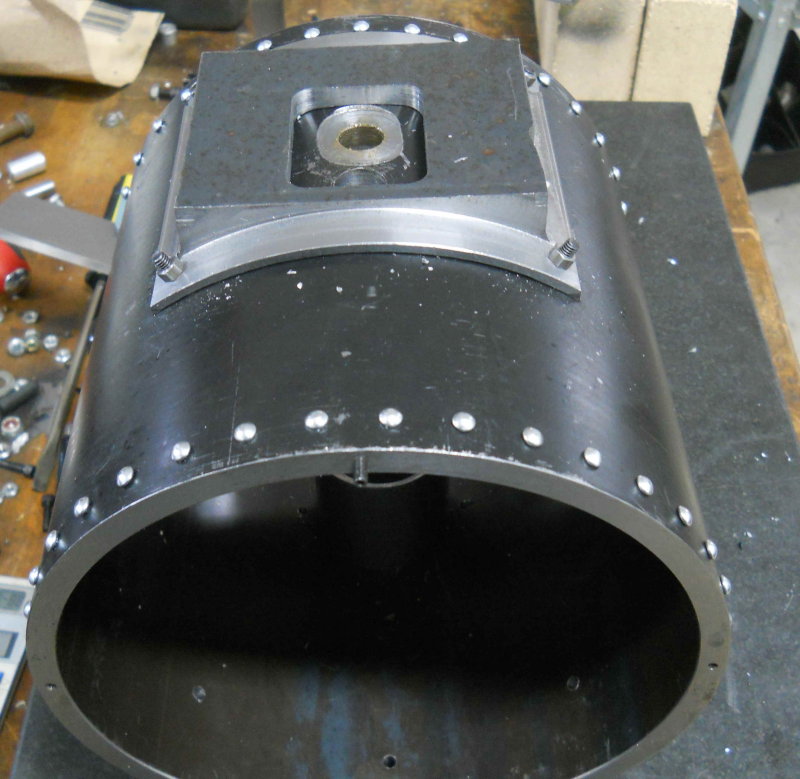

And installed in the supports:

If I need to remove the ash pan in the future, I can do so my removed the two screws and dropping the pan.

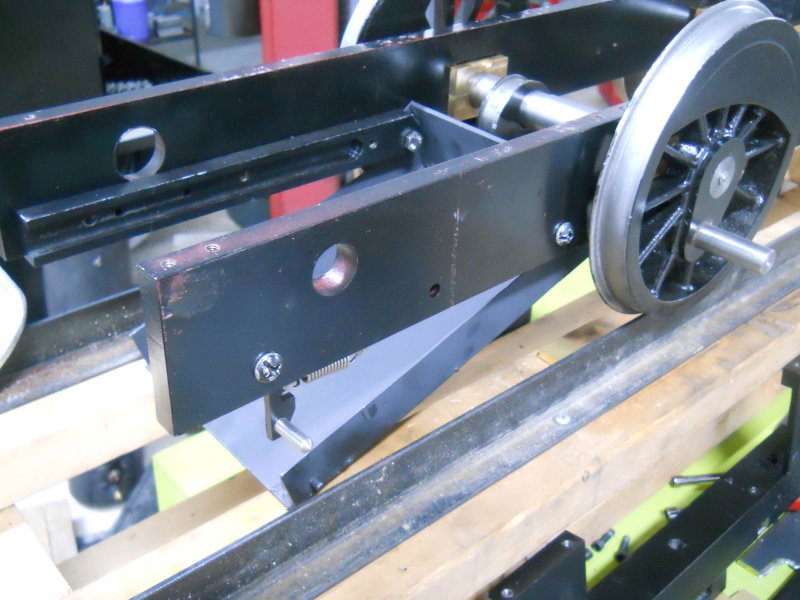

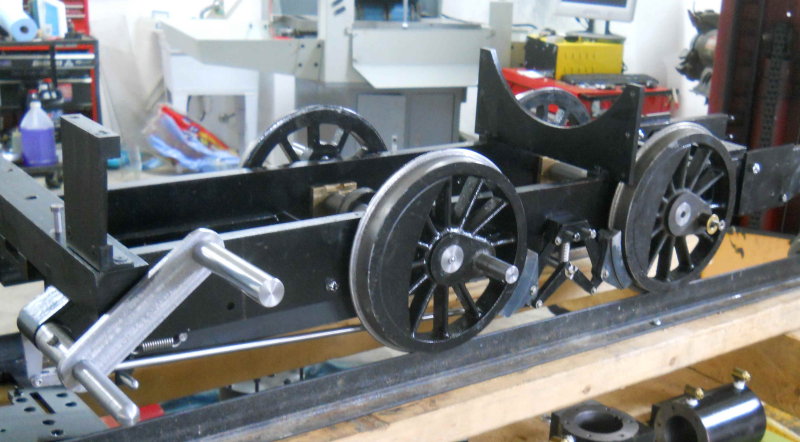

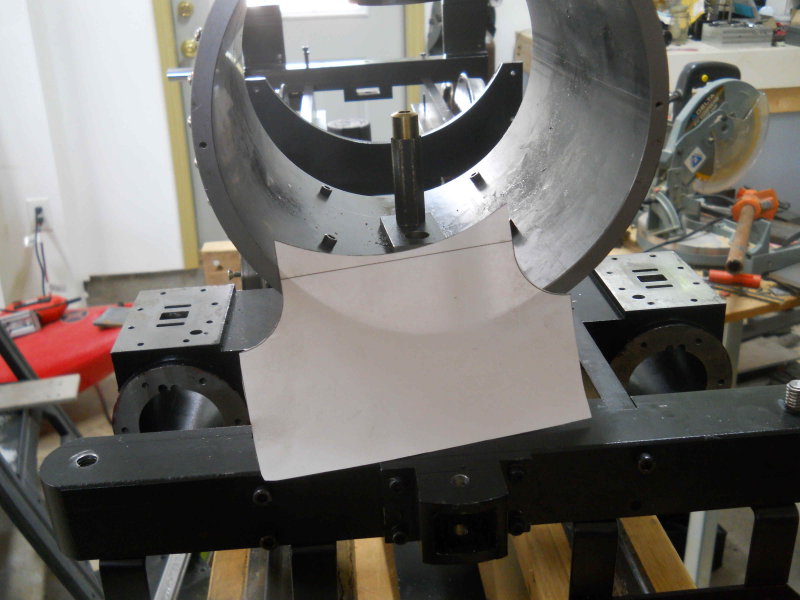

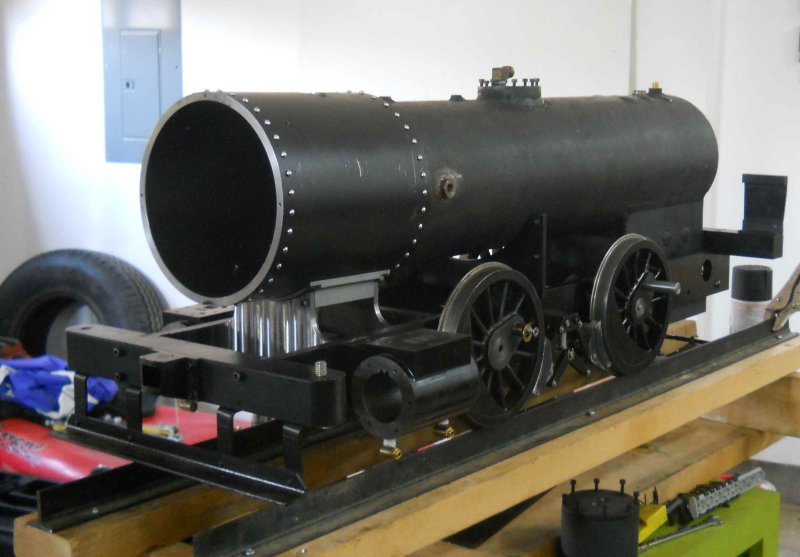

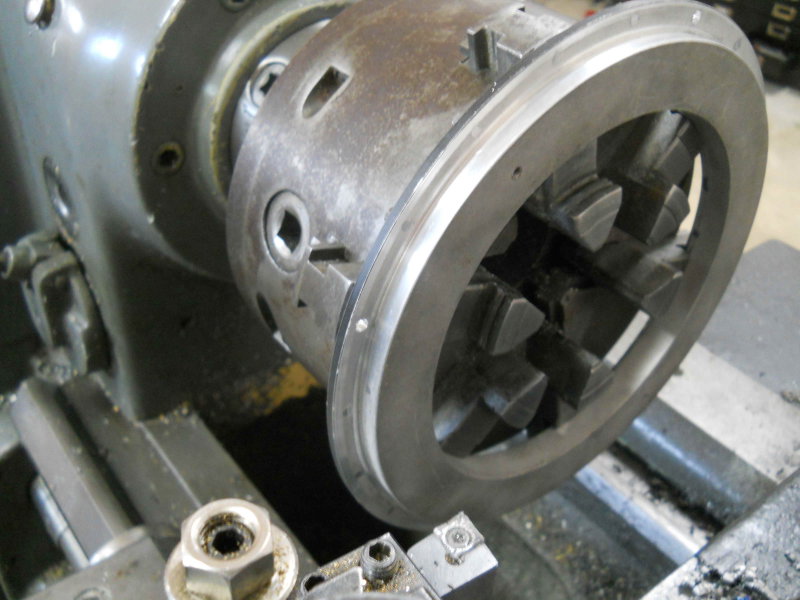

I started to reassemble the frame, and then to check the new quartering of the front axle. At that point I discovered I had quartered it backwards relative to the rear axle. Nothing to do but heat up on wheel, press it off, and redo the setup with the correct orientation. Compare this picture with the one show previously:

Now the right, horizontal, crank pin is rotated forward rather than back. Once it cures I'll mount to the frame and check it (with crossed fingers).