Another belated update.

I've been messing with the oil pump but eventually got it to what I thought would work. I cobbled it up to some pipework and gave it a whirl with the drill. It seemed to pump a reasonable volume of oil, so I rigged up a pressure gauge and tried again. 200psi! I suppose that's the power of hydraulics.

I then put a bleed valve in and ran it at 60psi. There still seemed to be a good oil flow, so, that'll do for that.

I then stripped it and anodised it, and made my common mistake of getting carried away with the dyes.

Still, it doesn't look bad enough to warrant doing it again so I'll stick with it for now.

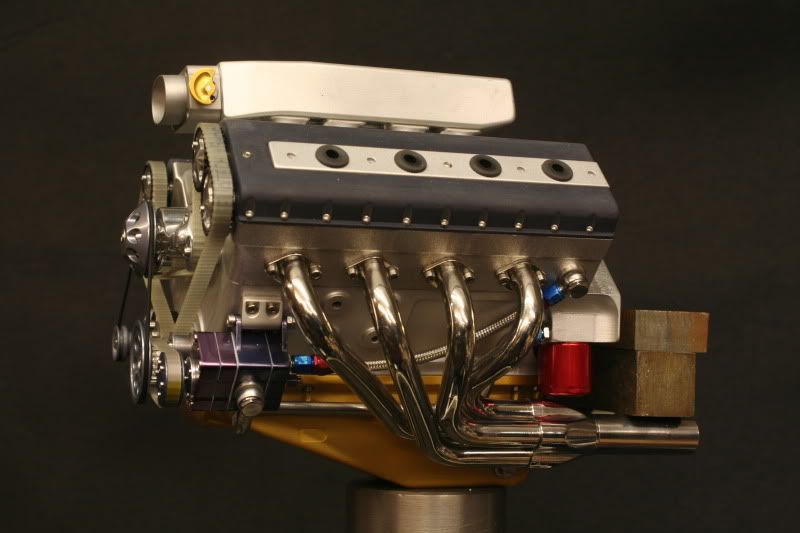

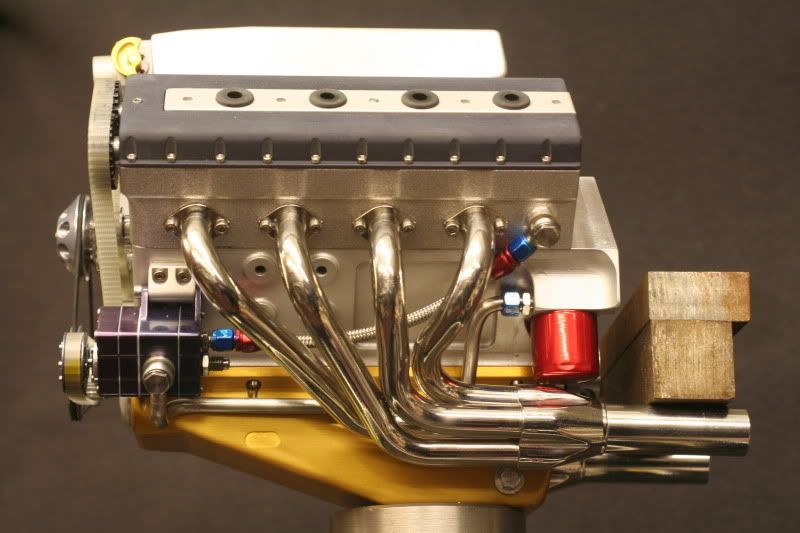

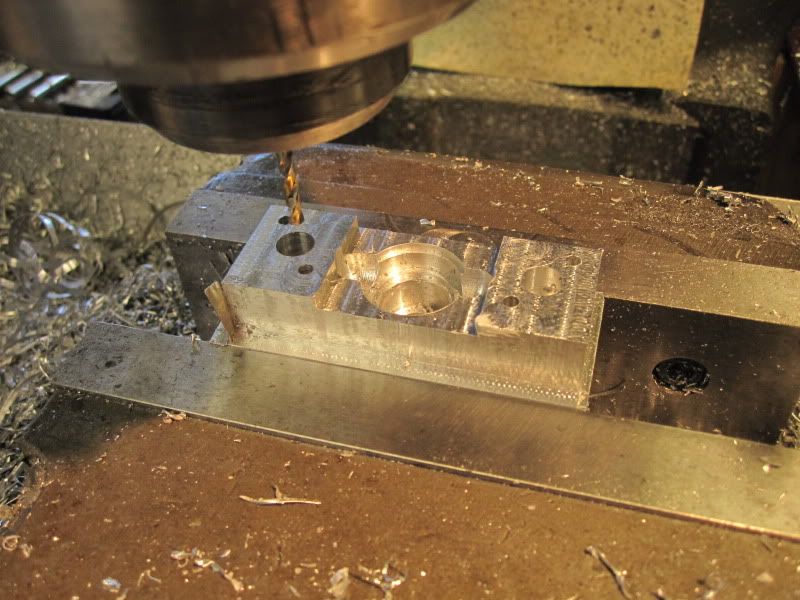

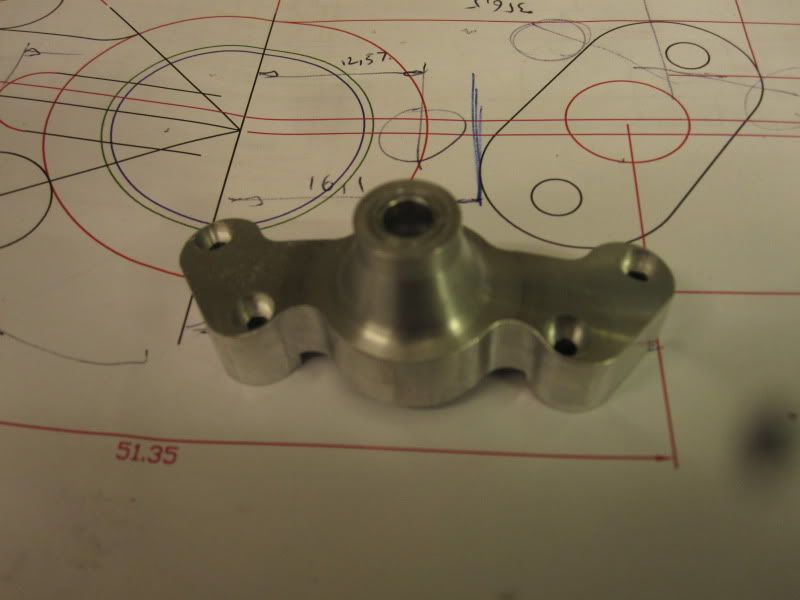

Then I drilled the block for some oilways, and made the screw on filter. This will be working but will probably just ouse a cobalt magnet to take the ferrous stuff out.

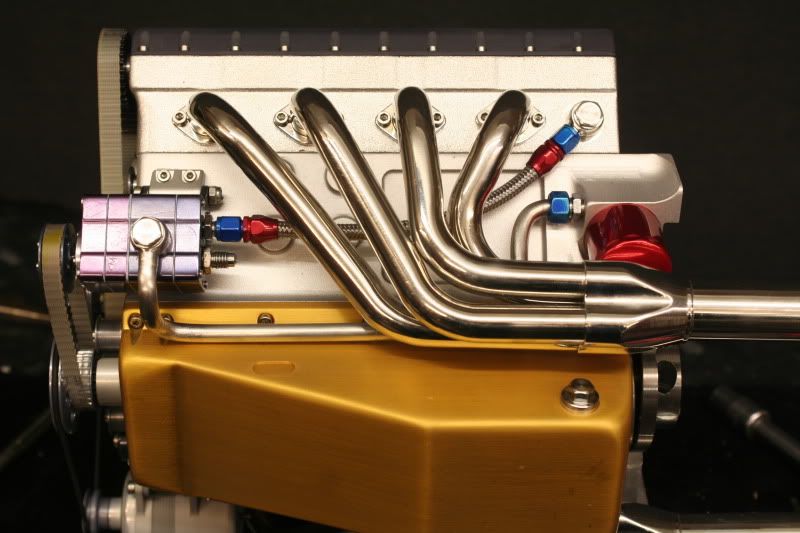

The pipe from the filter to the pump took more hours to make than I dare mention, but it was just about worth it.

The bends are really tight again, like the exhaust, and needed a bender making, and use of the low melting point alloy filler material.

I was fed up one day so I anodised the sump just for the hell of it, but it came out really well, much better than expected. and much better than the blue dye which doesn't seem to be working very well.

Next job is to make some more metal pipes and banjo fittings for getting the oil from the head to the block and the other head.

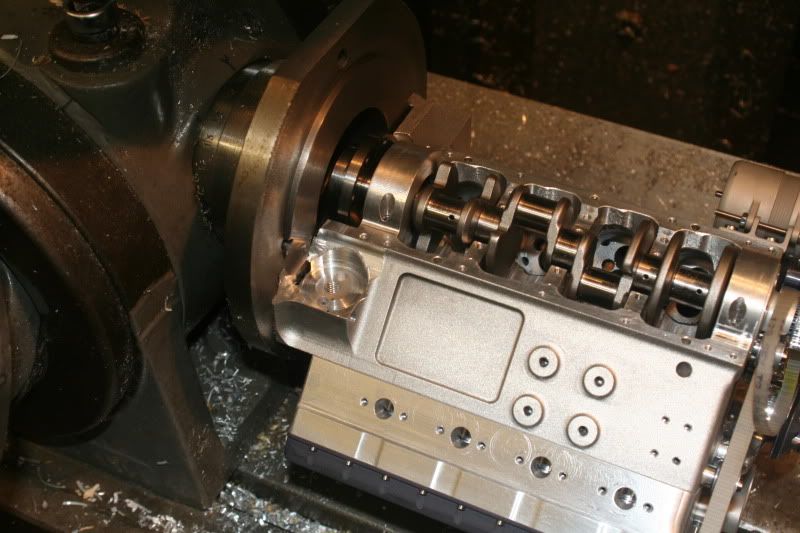

Someone asked what machines I had. Well I have an old manual Bridgeport, which is great, and a really old Union lathe, which is crap. Some pics of it at the end, with my incredibly untidy workshop. Believe it or not I know exactly where everything is!