- Joined

- Aug 8, 2009

- Messages

- 930

- Reaction score

- 12

Try to say that fast three times.

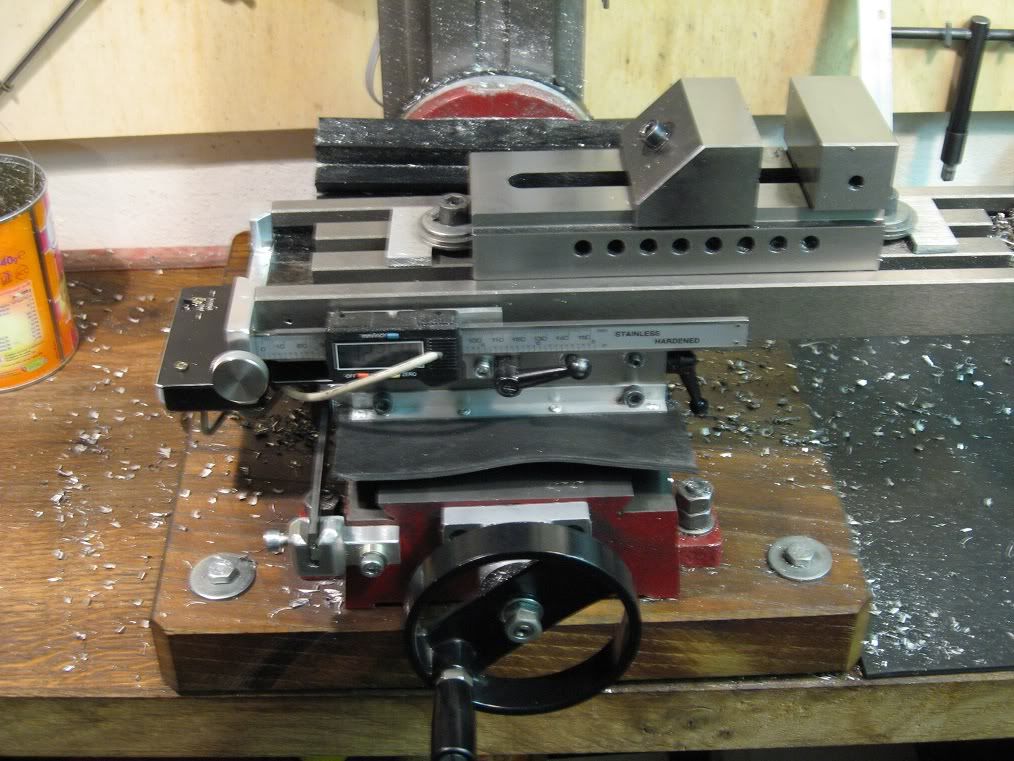

You know those accordion-shaped rubber doo-hickeys that keep the swarf from clogging things up below the table on the Seig X2 mill? Mine are starting to disintegrate. Was wondering what others here have come up with for replacement. I've thought about plastic/PVC sheeting but not sure how it holds up under severe bending, oils, etc. Maybe just rubber sheeting will do the trick.

-Trout

You know those accordion-shaped rubber doo-hickeys that keep the swarf from clogging things up below the table on the Seig X2 mill? Mine are starting to disintegrate. Was wondering what others here have come up with for replacement. I've thought about plastic/PVC sheeting but not sure how it holds up under severe bending, oils, etc. Maybe just rubber sheeting will do the trick.

-Trout