wheeltapper

Senior Member

- Joined

- Jun 25, 2010

- Messages

- 143

- Reaction score

- 14

Hi people, well I've finally bitten the bullet and started building this engine.

this won't be a blow by blow account, rather a show and tell as I (hopefully) finish a part.

It will also take me a fair amount of time as I have to save for the material and tooling required, I've already come to a stop on the head because I need a rotary table and they don't grow on trees.

first a pic of what it should look like.

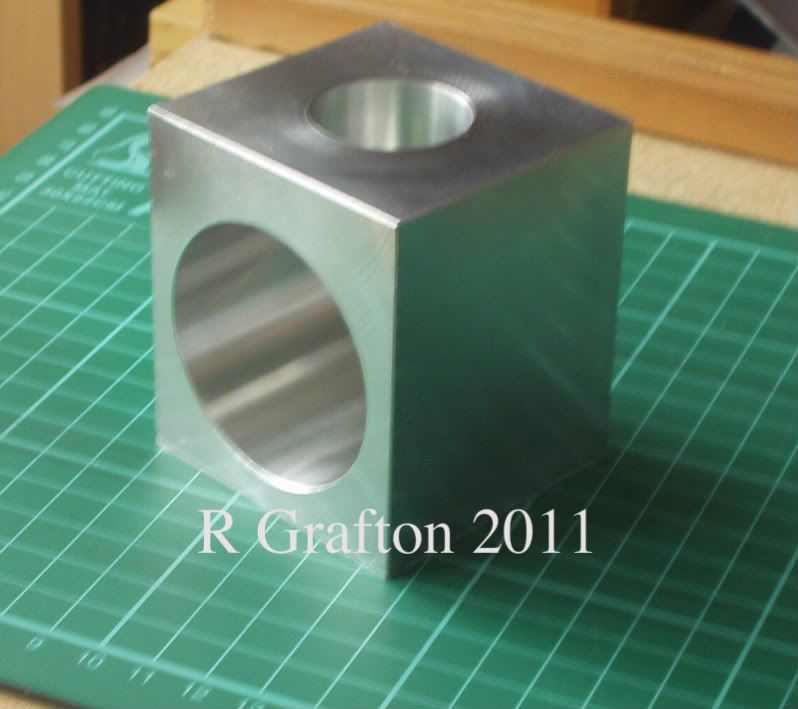

parts so far, cylinder jacket

crankcase nosepiece.

part finished head.

and crankshaft.

That's it so far.

next is get a square lump of ally for the crankcase.

expensive hobby this, ain't it

more to follow soon.

I hope :big:

cheers

Roy

this won't be a blow by blow account, rather a show and tell as I (hopefully) finish a part.

It will also take me a fair amount of time as I have to save for the material and tooling required, I've already come to a stop on the head because I need a rotary table and they don't grow on trees.

first a pic of what it should look like.

parts so far, cylinder jacket

crankcase nosepiece.

part finished head.

and crankshaft.

That's it so far.

next is get a square lump of ally for the crankcase.

expensive hobby this, ain't it

more to follow soon.

I hope :big:

cheers

Roy