You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Small V8

- Thread starter stevehuckss396

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

cfellows said:How can you resist the urge to try and start it? I would be cobbling things together at this point so I could try it out!

It's been 13 months so no reason to rush now. If I get the urge, I just walk over to the other bench and start the V4. I'm waiting for a friend to get the tubing bender finished. When he does the exhaust will be addressed and then I will have to figure out how to make sparkplug boots. I'm going to try to get these 2 items done soon and then make an attempt to start it. Now that the plans are released I don't feel like I need to rush anymore. I'm a bit relieved. I'm going to start working on the radiator and hope the tubing bender gets done soon.

Lakc

Well-Known Member

cfellows said:Looking real nice, Steve. How can you resist the urge to try and start it? I would be cobbling things together at this point so I could try it out!

Chuck

Its nice to know I am in good company with that thought, Chuck.

Brass and buffing wheels, they go together like peanut butter and jelly. ;D Steve that looks awesome!

Lakc said:Its nice to know I am in good company with that thought, Chuck.

Brass and buffing wheels, they go together like peanut butter and jelly. ;D Steve that looks awesome!

I had PB&J for lunch today.

BTW

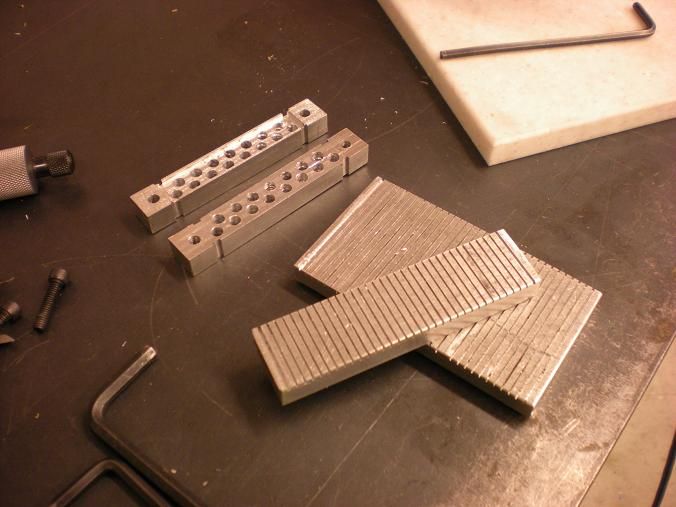

I have completed the fixtures for the radiator. I have to believe there will be a high speed run to the hobby shop for some tubing and 1/2 inch wide fin stock.

Lakc

Well-Known Member

<---- Grabs popcorn!

Never seen this done before, this is gonna be fun.

Never seen this done before, this is gonna be fun.

Lakc said:<---- Grabs popcorn!

Never seen this done before, this is gonna be fun.

I had popcorn last night.

stevehuckss396 said:When I started this project it was with the plan to make a V8 that was less complex than the current designs out there and smaller for the folks with smaller machines than a Bridgeport and 48 inch lathe.

Steve, I have my finger poised over the PayPal "Send Money" button. Before I mash that sucker down, can I build the Demon with a Seig X2 mill and 7x12 lathe?

T70MkIII said:Steve, I have my finger poised over the PayPal "Send Money" button. Before I mash that sucker down, can I build the Demon with a Seig X2 mill and 7x12 lathe?

There are a few things that will be difficult. One that comes to mind would be boring the crank and cam bores. They are 1/2 and 5/8 inch bores that are 5 inches deep. Hard to do in a tiny mill but might be doable in the lathe with a boring bar between centers. If you are creative and get thru making the block the other parts should be no trouble.

The intent was to design a small V8 for the guys with smaller machines. Harder than i thought but doable.

All that being said, I don't know! Being honest!

T70MkIII said:I've never seen a radiator buildup either. I'm watching, bourbon in hand...

Had Burbon for lunch today! Kidding!!

It figures, I am one brass slat short and one piece of tubing short. I have been buying brass a little at a time in preperation for this. Go to the hobby store and clean out the last 5 pieces they have because they only stock 5 at a time. One more trip and I would have had it covered. Looks like that high speed run is on for tomorrow.

Glad to hear it! *beer*stevehuckss396 said:Had Burbon for lunch today! ...

Re boring bar in the lathe - I was having similar thoughts. I know this build isn't for the inexperienced, faint of heart or terminally dense, but I'm going to order your plans anyway.

Lakc

Well-Known Member

Oddly enough, if you order the right size pieces from Mcmaster, you get K&S. Thankfully, most hardware stores have that ubiquitious rack of goodies as well.

I made the trip to the hobby store and bought the balance of the needed brass. I cut all my pieces up and prepped the end plates.

I loaded the end plates into the recess in the fixture.

Then all the fins are loaded up. I cut the fins about .100 longer than is needed. After assembly the plan is to mill the fins to size.

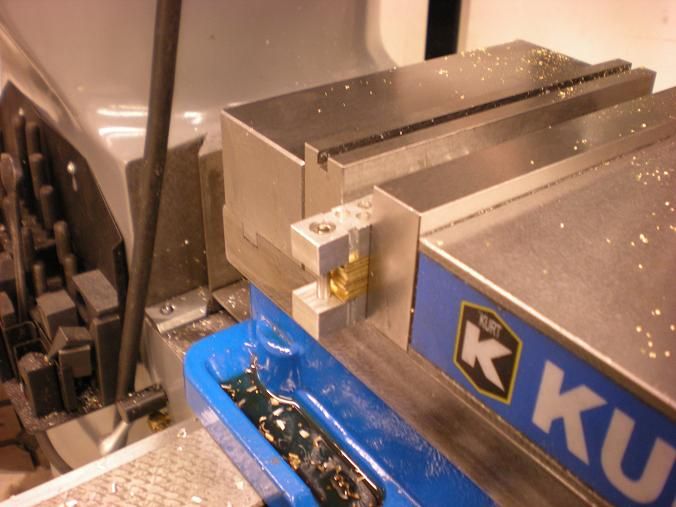

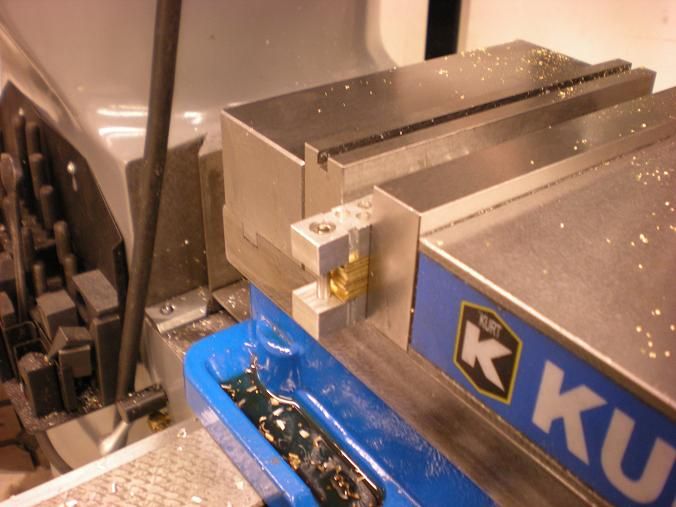

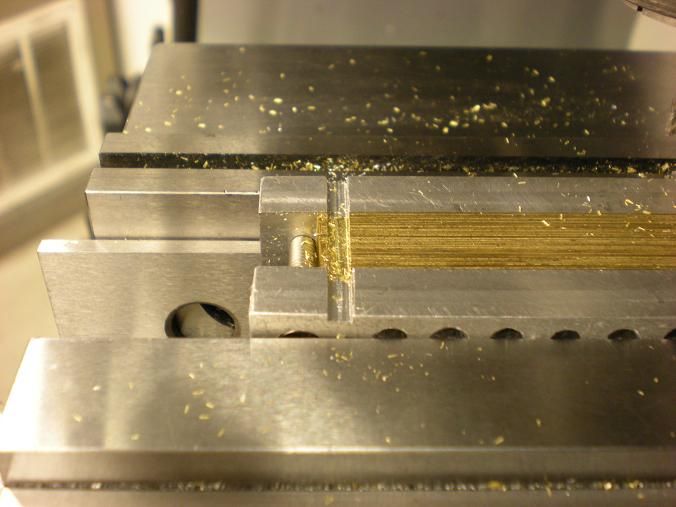

Then the fixture is pinched in the vise to align the fins in the fixture and tightened up.

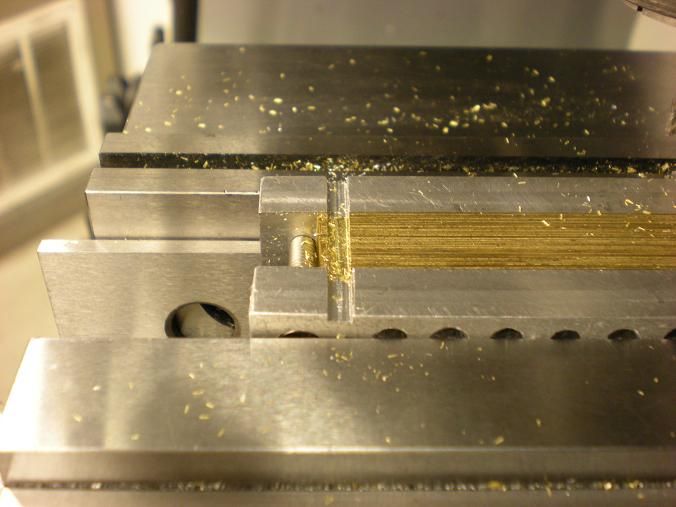

Next the holes are drilled thru. The tubing I bought was running a bit large so I bumped up my drill size to .003 larger than the tubing. Then the step in the side is milled on both sides

Now the pieces get loaded into the other fixture. When they come out of the drilling fixture make sure they stay in a stack and do not flip them end for end. If you keep them straight the tubes will slide right thru the stack and into place. I made the tubes extra long also so I will need to mill them to size later. I placed all the fins into the slots and slid the first tube thru the stack. Then I placed the top piece of the fixture on the stack.

Then the remaining tubes are slid into the stack. I managed to soft solder the fins to the outside tubes but I cant get enough heat to finish the end plates. Seems I'll be looking for a new torch.

I loaded the end plates into the recess in the fixture.

Then all the fins are loaded up. I cut the fins about .100 longer than is needed. After assembly the plan is to mill the fins to size.

Then the fixture is pinched in the vise to align the fins in the fixture and tightened up.

Next the holes are drilled thru. The tubing I bought was running a bit large so I bumped up my drill size to .003 larger than the tubing. Then the step in the side is milled on both sides

Now the pieces get loaded into the other fixture. When they come out of the drilling fixture make sure they stay in a stack and do not flip them end for end. If you keep them straight the tubes will slide right thru the stack and into place. I made the tubes extra long also so I will need to mill them to size later. I placed all the fins into the slots and slid the first tube thru the stack. Then I placed the top piece of the fixture on the stack.

Then the remaining tubes are slid into the stack. I managed to soft solder the fins to the outside tubes but I cant get enough heat to finish the end plates. Seems I'll be looking for a new torch.

- Joined

- Jul 16, 2007

- Messages

- 2,979

- Reaction score

- 1,046

Hi Steve,

The radiator construction looks good. It looks like your setup plates are aluminum. I have tried to do similar things in the past and found that the aluminum just sucks the heat away from what you are doing. It might be well worth the time spent to make your guide plates from 12L or the like. The steel gets hot but doesn't dissipate the heat like aluminum.

George

The radiator construction looks good. It looks like your setup plates are aluminum. I have tried to do similar things in the past and found that the aluminum just sucks the heat away from what you are doing. It might be well worth the time spent to make your guide plates from 12L or the like. The steel gets hot but doesn't dissipate the heat like aluminum.

George

gbritnell said:Hi Steve,

The radiator construction looks good. It looks like your setup plates are aluminum. I have tried to do similar things in the past and found that the aluminum just sucks the heat away from what you are doing. It might be well worth the time spent to make your guide plates from 12L or the like. The steel gets hot but doesn't dissipate the heat like aluminum.

George

I was going to silver solder the end plates on. That way when I soft solder the tanks on I wont unsolder the end plates. I was worried that I would silver solder the steel to the brass.

GailInNM said:Congratulations on the nice comments in editorial section of current modelenginenews.org.

Thanks Mr Graham! Ron has been very kind to me over the years.

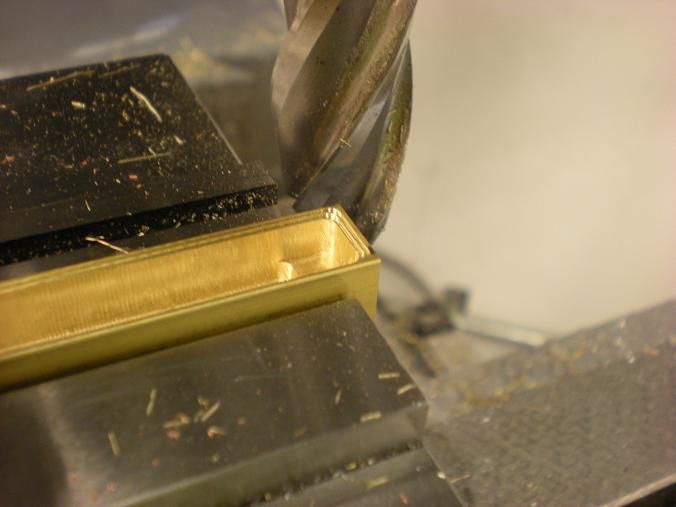

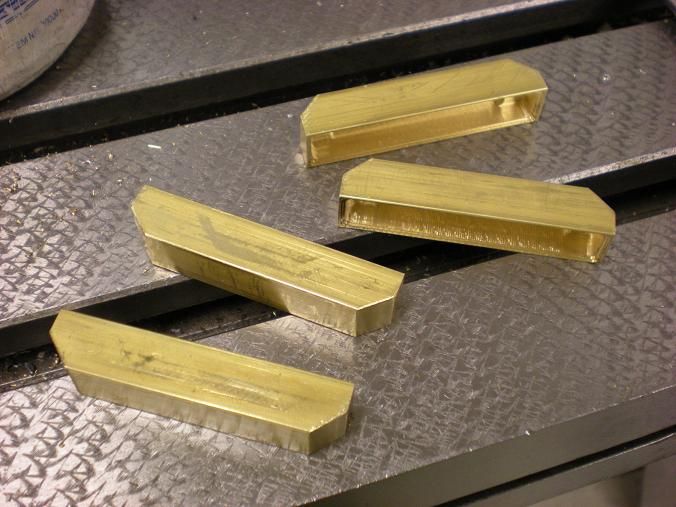

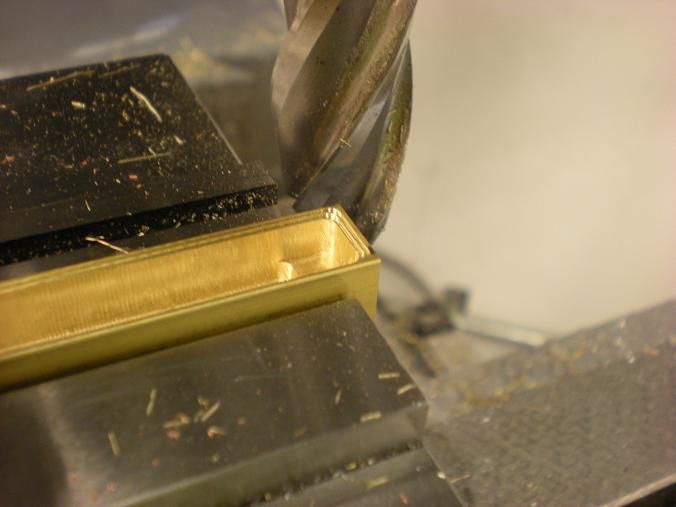

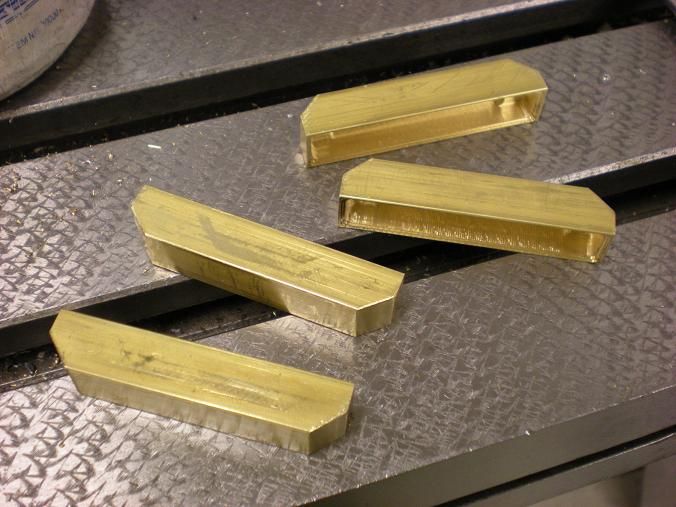

Made the tanks for the radiator today. Started out by milling the pockets out in some 1/2 X 1/2 inch brass.

Then manually I milled the piece to length.

Then I milled the angles in the ends of the tanks.

Then I proceeded to drill the wrong size holes in the tank for the fittings!!! AAARRRRGGGG!!!

I think im just going to make fittings that fit the holes rather than make new tanks. Not happy!!

Then manually I milled the piece to length.

Then I milled the angles in the ends of the tanks.

Then I proceeded to drill the wrong size holes in the tank for the fittings!!! AAARRRRGGGG!!!

I think im just going to make fittings that fit the holes rather than make new tanks. Not happy!!

Similar threads

- Replies

- 413

- Views

- 38K