- Joined

- Aug 8, 2009

- Messages

- 930

- Reaction score

- 12

It doesn't take long for my back to start aching when I am using the mini lathe. It is at bench height and because my eyes ain't what they used to be, I have to lean in to get a good look at things (good thing I cut off my hippie hair years ago). So I've been thinkin' about it some. Earlier this year, I bought a new office desk chair to replace the executive-type chair I've had for a few years in the computer room. The outgoing chair was still in good shape and I hated to get rid of it so I moved it into my workshop and put it in front of my mini mill and working bench. Lo and behold, that was the best move I've made in a long time because it put me at just the right height for milling without straining my back. The work is at eye level now and my butt feels better resting on that soft chair than it did on the stool I was using. Additionally, I can lean back, kick the feet up onto the bench in between milling passes, listen to the music and ponder my next move. It's made my shop a very comfortable place to be. *beer*

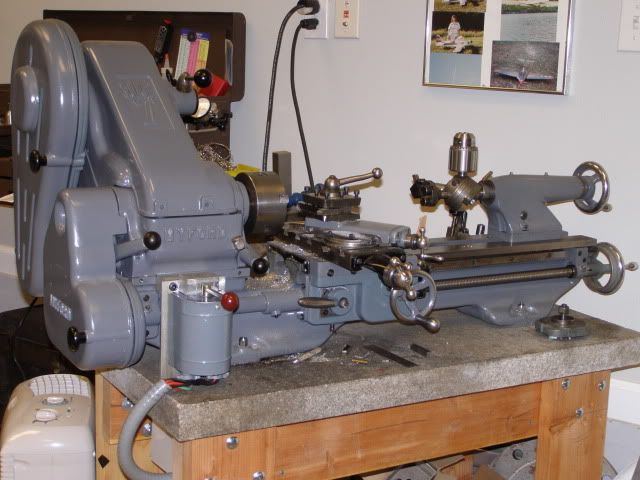

Which brings me to the lathe. Most times I can't even sit on my tall bar stool when turning a part because the tool rest blocks my view of the action so I need to stand up and bend over to see. Not a good thing. What if I built a 24" high stand for the lathe so I could see over the tool rest while seated in my executive office chair? Anyone tried this setup? I can see it now...a low rider lathe...Barry White on the stereo....slow jammin' the brass..... (too much Jimmy Fallon).

Which brings me to the lathe. Most times I can't even sit on my tall bar stool when turning a part because the tool rest blocks my view of the action so I need to stand up and bend over to see. Not a good thing. What if I built a 24" high stand for the lathe so I could see over the tool rest while seated in my executive office chair? Anyone tried this setup? I can see it now...a low rider lathe...Barry White on the stereo....slow jammin' the brass..... (too much Jimmy Fallon).