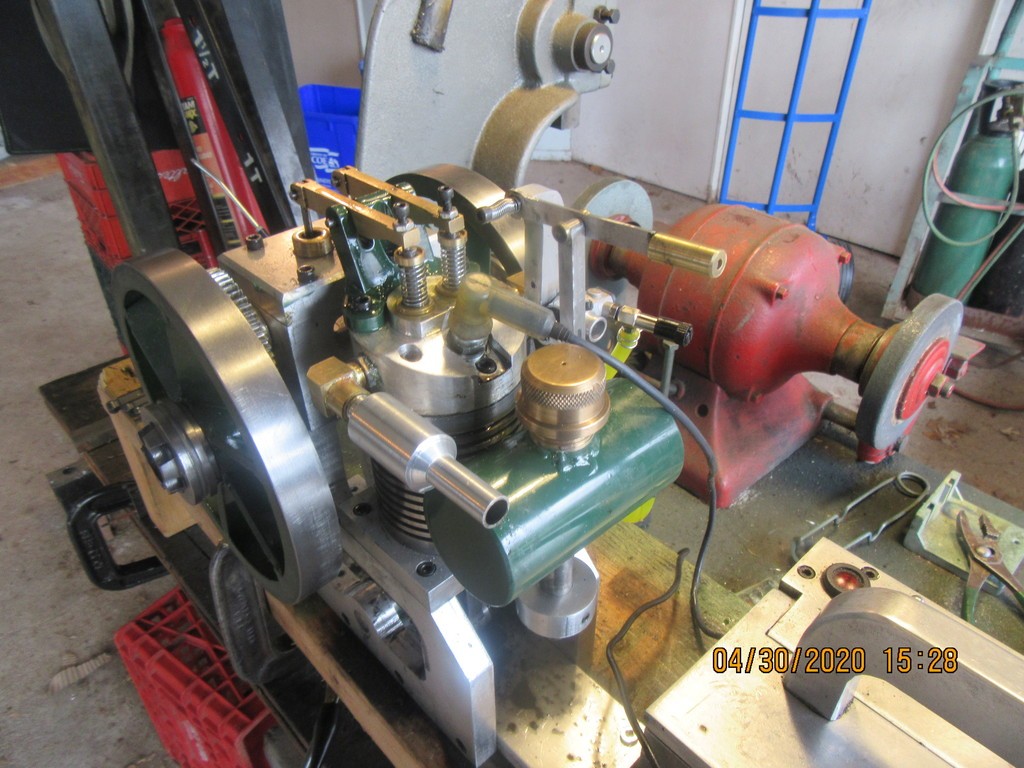

YES!!!--The engine runs. It had fairly weak compression to begin with, gave a lot of pops and farts, but didn't want to run on it's own. I advanced the timing about 10 degrees, but no joy. Everything was set to "optimum" but it didn't want to keep running on it's own. I have a new (used)1/4 horsepower electric motor that I bought a couple of months ago. I set it up and ran a v-belt from one of the motor pulleys to the offside flywheel, turned on the switch and let the electric motor run the engine. The engine was firing right along with the motor running it. The cylinder got warm and the exhaust was warm, so I just let it run. I knew that with combustion happening, the valves would begin to seal better and the rings would seat. After about 15 minutes I stopped everything, took the belt off, and started the engine the normal way, with my electric drill. I am very pleased, the engine is a runner. Now it's just a matter of taming it a bit to get a good idle and throttle response. Now that I know the engine runs okay, I will sell the plans for $25 Canadian---contact me by email. I haven't been able to get Youtube to work for me for the last month or so, but tomorrow I will get a video of it with my camera and see if my wife can open a new account on Youtube. If she can't I'm going to have to figure out another way of getting a video to post.---Brian