Congrats Brian, another top engine with reverse

Cheers

Andrew

Cheers

Andrew

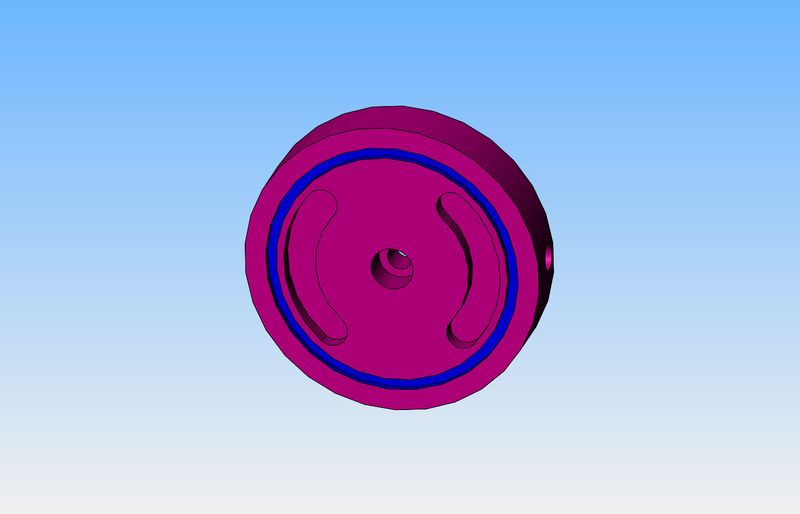

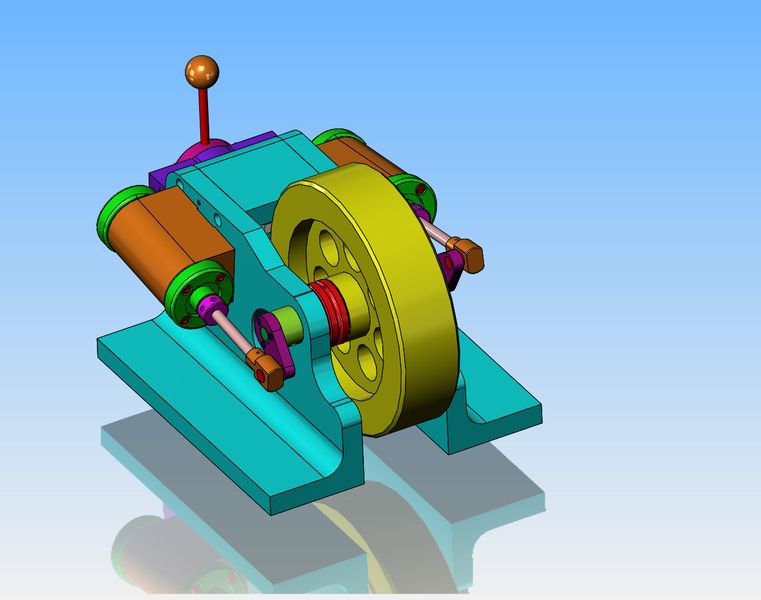

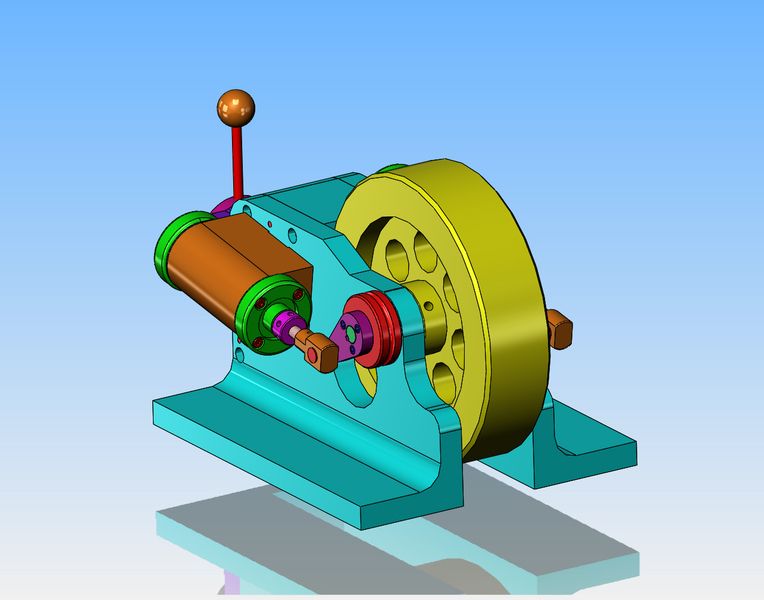

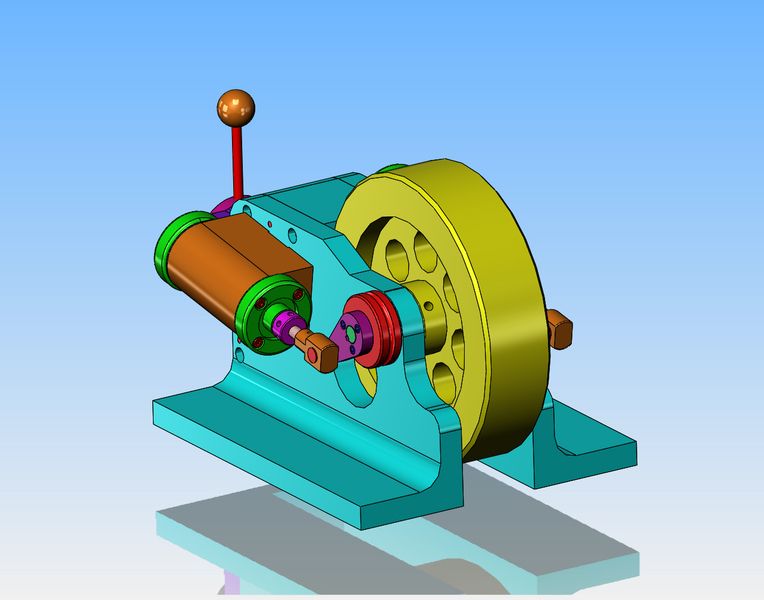

Would adding the pulley outboard put too much pressure on the crank on that side? But then, you'd have to disassemble the engine to put a belt on or take it off...Oh my god---A GIANT BRAIN FART!!!!! I spent a goodly share of yesterday designing all of the components required to widen the engine and add a take off pulley beside the flywheel. Got up this morning and looked at it and thought "I could just put the pulley on the crank arm without changing anything else". Musta been that funny stuff I was smoking yesterday---

Enter your email address to join: