stragenmitsuko

Well-Known Member

- Joined

- Jan 19, 2016

- Messages

- 326

- Reaction score

- 143

Let me start by saying I'm not an insert guy .

I like my hss tools , I like to grind them , and I 'm the proud owner of a

clarkson MKIII t&c grinder . Never needed inserts , and hardly use them .

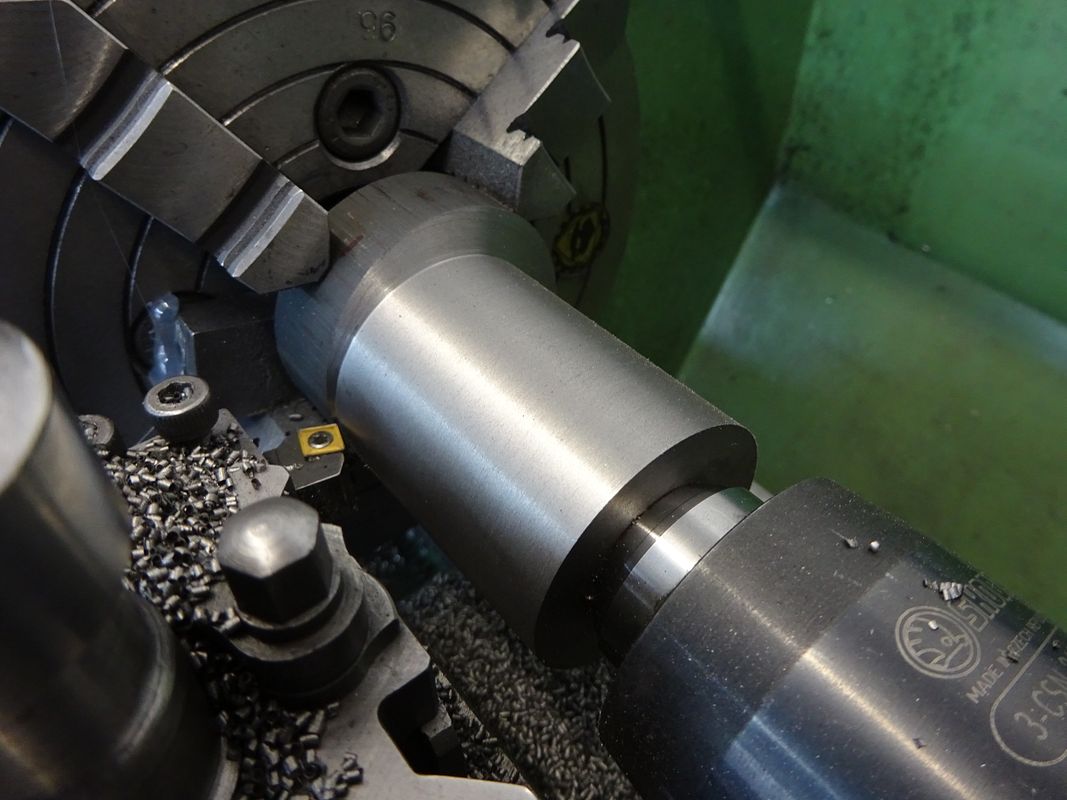

That said , I recently got some lathe tools with ccgt0903 inserts .

CCGT is ment to be used on alloy's .

So I gave them a try .

And I must say , I'm speechless with the way they perform .

These inserts have a high positive rake , are rasor sharp , and leave a bright shiny finish when turning aluminium .

Even the worst alum I have ( the home cast variety ) machines to a very acceptable finish , with no sticking of the chips to the tool .

Thought I'de share that .

Pat

Btw I wonder what material these inserts are made of . It doesn't look like carbide .

I like my hss tools , I like to grind them , and I 'm the proud owner of a

clarkson MKIII t&c grinder . Never needed inserts , and hardly use them .

That said , I recently got some lathe tools with ccgt0903 inserts .

CCGT is ment to be used on alloy's .

So I gave them a try .

And I must say , I'm speechless with the way they perform .

These inserts have a high positive rake , are rasor sharp , and leave a bright shiny finish when turning aluminium .

Even the worst alum I have ( the home cast variety ) machines to a very acceptable finish , with no sticking of the chips to the tool .

Thought I'de share that .

Pat

Btw I wonder what material these inserts are made of . It doesn't look like carbide .