Running a 20:1 mix which is a bit oil heavy, but shouldn't keep the engine from firing and running.Brian, what is your fuel mix? (Just curious, I don't have anything to suggest.)

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Old School Barstock 2 Stroke

- Thread starter Brian Rupnow

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

canadianhorsepower

Well-Known Member

- Joined

- Oct 22, 2011

- Messages

- 1,671

- Reaction score

- 324

Running a 20:1 mix which is a bit oil heavy, but shouldn't keep the engine from firing and running.

WAY to much oil.. this is not a diesel Rof}Rof}

not lest then 50:1

a small trick install a bull horn pipe on your intake

and try it then

What on earth is a "bull horn pipe"?

canadianhorsepower

Well-Known Member

- Joined

- Oct 22, 2011

- Messages

- 1,671

- Reaction score

- 324

What on earth is a "bull horn pipe"?

OUPS I mean a boost tube

in your case a small co2 cartridge from a air pistol would be good enough

The bottle MUST be upward parralel to your cylinder

it serve as a mixture reservoir

Last edited:

There are no leaks in the crankcase. However, that being said, there are no shaft seals on this engine. I am completely out of tricks that I would normally use to start an engine.---tried them all yesterday. The engine fires, and fires very consistently when turned by the drill motor, but won't keep running on it's own. I have tried the ignition timing on every setting, and although it makes a difference, it doesn't make enough difference for the engine to catch and "take off". Likewise, I have tried every possible needle valve setting. This engine seems to fire more consistently on what I would deem a very rich mix if it was a four cycle engine. Today I will do the "easy" stuff---I will start by lowering the gas tank to see what effect that has. I will try and feel for carburetor suction, and may put a piece of clear plastic tube from the intake pipe to a glass of water to see if it is blowing bubbles when I turn the engine over by hand to see if the round ball in the carburetor is sealing the way it is supposed to. If that fails, i may try glow fuel and a glow plug, which are recommended for this engine by the original designer. (He claims that though the engine will run on gasoline, it starts much easier on a glow plug set-up.) What do people generally do for crankshaft seals on an engine like this, where the crankshaft is only 3/8" diameter?----Brian

canadianhorsepower

Well-Known Member

- Joined

- Oct 22, 2011

- Messages

- 1,671

- Reaction score

- 324

However, that being said, there are no shaft seals on this engine. engine like this, where the crankshaft is only 3/8" diameter?----Brian

Brian,

a 2 stroke engine is like a balloon ANY leak will turn into a disaster.

make an adapter to seal close your exhaust and intake port (after the carb)

apply a pressure small 10 lbs in the spark plug hole and dip it into water

any bubble means trouble. Then apply 10 hg of vacuum and it should hold

steady .

As for the 3/8 id seal it's pretty common on chain saws and boat.

I would doubt that it will ever start and run properly without seal

on the crank

good luck

http://www.timken.com/en-us/products/documents/seal-specification-guide.pdf

page 17 has all you need

Last edited:

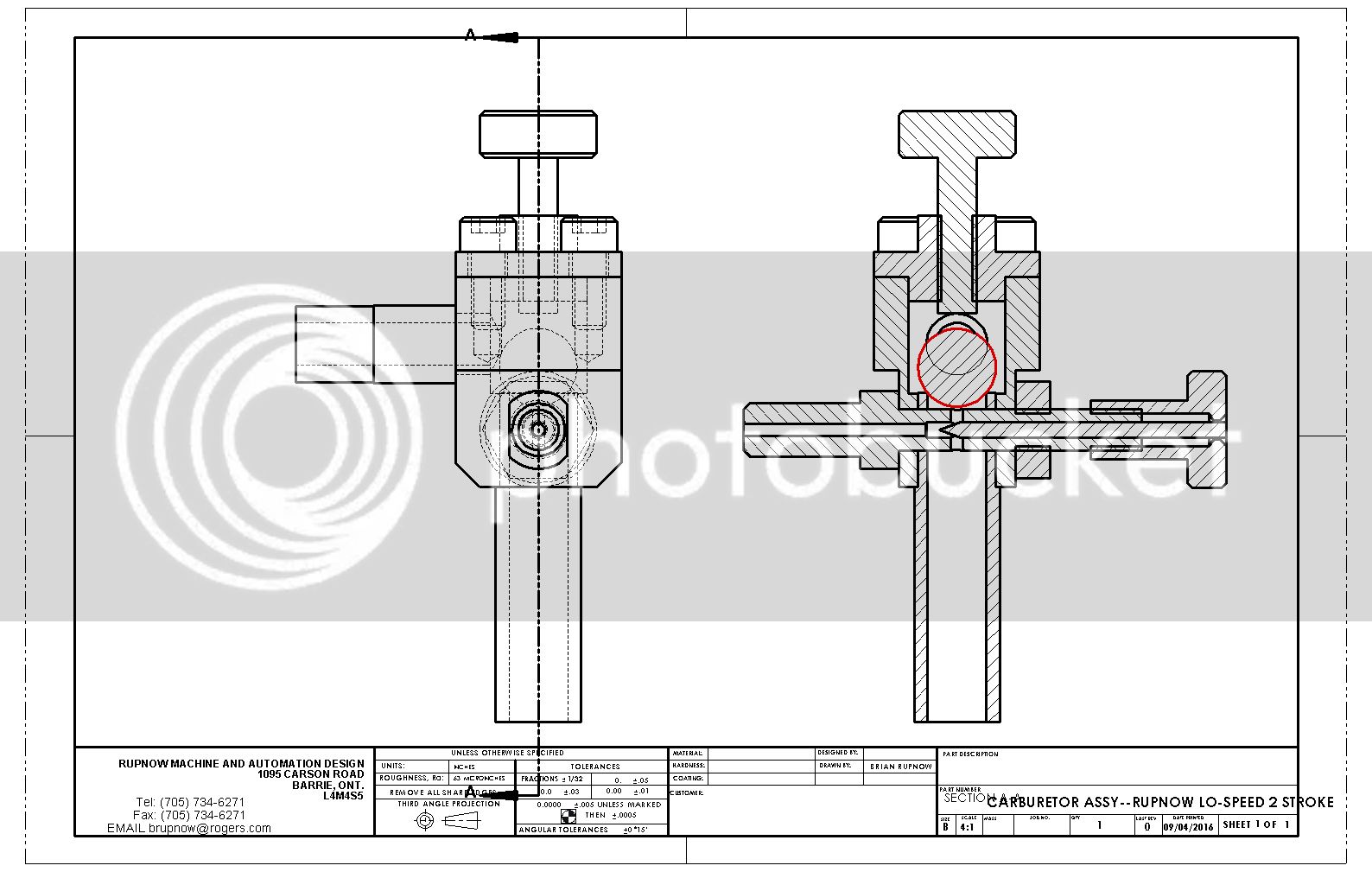

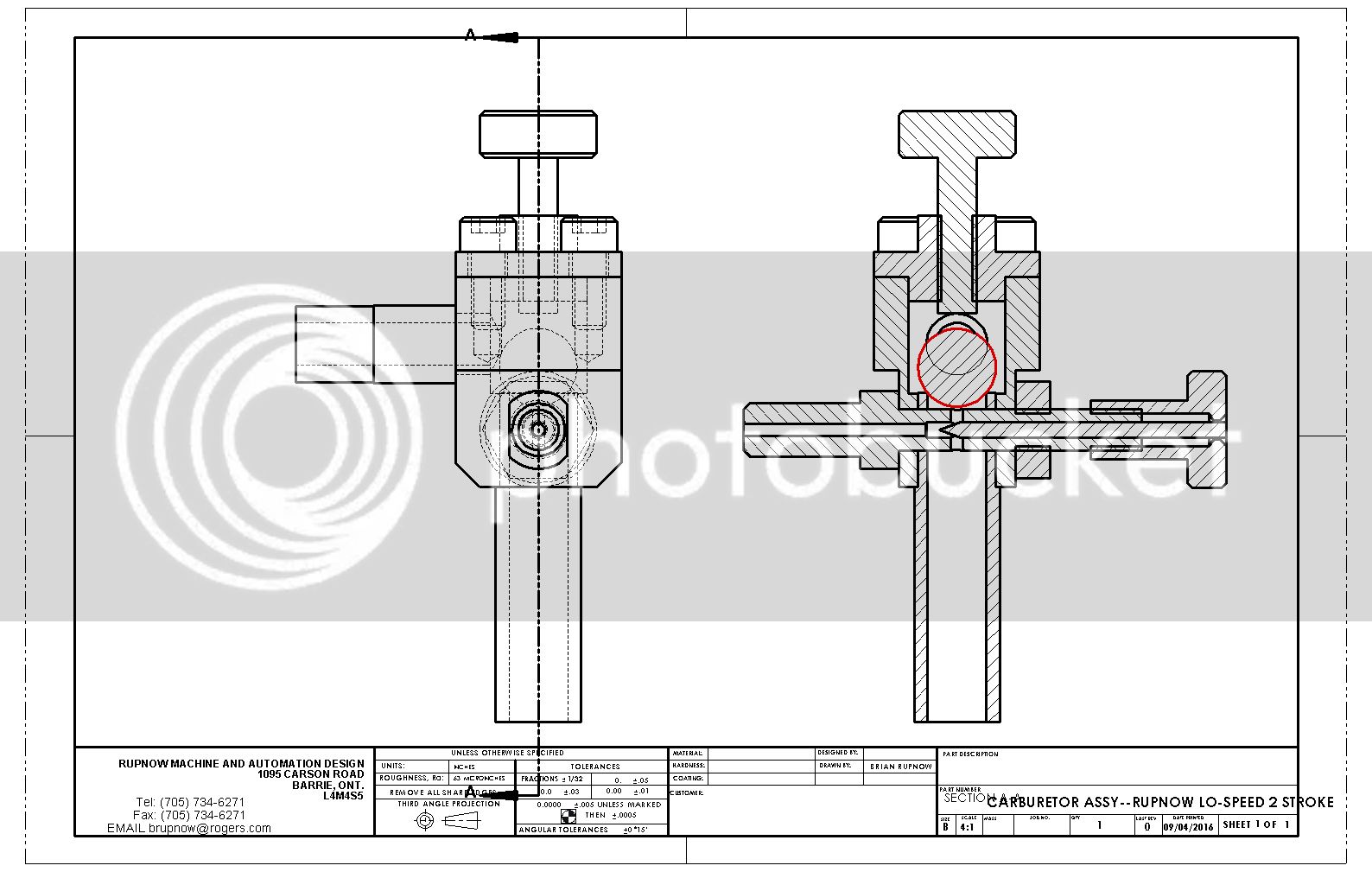

Today I have my detective hat on, and I have found a clue!! I removed the carburetor and holding it in the same position as when it is mounted, I blew air up the intake pipe. Okay, good--air passes thru just like it is supposed to. Then I sucked, expecting to not be able to get any air-(the needle valve was fully closed) -the check ball should have stopped any air going in the opposite direction, however----it didn't!!! WHAT---IT ISN'T SUPPOSED TO DO THAT!!! This called for disassembly of the carburetor, and inspection of the seat against which the ball should set to stop reverse air flow. the seat should have some kind of mark indicating that the ball was seating fully against it.---it didn't. I could just make out what looked like a mark on top of the fuel jet tube which sets directly below the ball seat. A careful measuring of the ball I have in there shows that it isn't 0.250" diameter as I thought. It is only 0.235" diameter. If you look at the drawing, the ball is colored red. You can see that with any decrease in diameter, the ball is going to rest on top of the fuel jet and not seal on the seat.--and that is exactly what has been happening. Now I have to see if I have a .250" diameter ball, or decide to wait until Monday and hope that Canadian Bearings in Barrie has the 1/4" balls in stock.

For the princely sum of $5.25, I am now the proud owner of 250 steel balls, 1/4" diameter, purchased from Canadian Tire (slingshot ammunition). Thank you to Wagonmaker in Lindsay, Ontario for the suggestion. I don't think these are bearing quality balls, but for a ball poppet valve they should work just fine.--And yes, I have already tried the "Suck and blow test" with one in the carburetor body, and they work fine.

The larger check ball done the trick!! I dropped the gas tank about 1 1/4", reassembled everything, and away it went. This makes me feel really good. One of the things that can not be stressed strongly enough, is that with these little engines you have to become an expert trouble-shooter. If it doesn't fire up after the first two hours of tinkering with it, then you have to have enough experience to figure out the reason and correct it. Thank you very much to all of you who have followed this build thread.---Brian Rupnow

[ame]https://www.youtube.com/watch?v=BjNhVsfEDMI&feature=youtu.be[/ame]

[ame]https://www.youtube.com/watch?v=BjNhVsfEDMI&feature=youtu.be[/ame]

After much playing with this engine this morning--(which in itself is a problem, because it's still below freezing outside, and I'm running this thing in my office with the door propped open to keep from gassing myself, and my arse is freezing off) I have determined that the top end speed is in the 1800 to 2000 rpm range with my laser tachometer. The bottom speed that I am able to obtain is about 850 rpm, which is a far cry from the supposed 400 rpm figure that was given with the casting set drawings. I'm running Coleman fuel (Naptha gas) with 10% synthetic oil added. The throttle response is not great, and it goes from high speed to low speed all within one turn of that threaded adjustment which bears against the top of the ball in the carburetor to limit how far the ball can lift off it's seat. The thread on that part is 40 TPI. I guess that on these old original marine engines, there wasn't a lot of requirement for a real wide range of speeds. When turning the flywheel by hand, it feels far different than turning a four cycle over by hand. It not only has excellent compression as the piston is going up in the cylinder, but what feels really strange is that you can also really feel the compression when the cylinder is going down in the cylinder as it compresses the fuel/air mix in the crankcase. The engine doesn't have any problems driving the gear pump, and as you can see in the video I am getting a good flow of cooling water with the pump running at 1/2 the engine rpm.

canadianhorsepower

Well-Known Member

- Joined

- Oct 22, 2011

- Messages

- 1,671

- Reaction score

- 324

. . It not only has excellent compression as the piston is going up in the cylinder, but what feels really strange is that you can also really feel the compression when the cylinder is going down in the cylinder as it compresses the fuel/air mix in the crankcase. .

Brian,

you probably feel the vacuum forming when you are going down,

it sur as hell not compression.

you should try one of those tube I talk to you about

it would help cause you have a very short intake track

good luck

nice work BTW

Luc--You were right. It was suction on the piston I was feeling. I tried it with the spark-plug removed, and there is no compression at all.---Brian

Last edited:

Guys--If the weather ever warms up and if it ever quits snowing here, I will move my act out to the main garage where I can open both the big doors and do a real video. I will show this engine at it's lowest rpm and it's top rpm, and maybe get a shot from the other side where the drive pulleys are set up to drive the waterpump. We got our April weather in March and set record high temperatures, but now we're getting out March weather in April, and believe me, nobody's enjoying it very much.

And Oh yes, just to set the record straight--I opened the container with my sample of j.b. weld submerged in Naptha gas this morning and checked it out. Naptha gas (Coleman fuel) has absolutely no effect on the j.b. weld.

- Joined

- Feb 17, 2008

- Messages

- 2,326

- Reaction score

- 440

Not that you need any further confirmation but:

http://www.jbweld.com/pages/faqs

"When fully cured, J-B Weld is completely resistant to water,

gasoline, and about every other petroleum product or

automotive chemical."

Also other useful info about JB weld on that page.

Gail in NM

http://www.jbweld.com/pages/faqs

"When fully cured, J-B Weld is completely resistant to water,

gasoline, and about every other petroleum product or

automotive chemical."

Also other useful info about JB weld on that page.

Gail in NM

Gail--I only conducted that series of tests because some "knowledgeable person"over on another forum posted that the j.b. weld would go all "gooey and turn to mush" in the presence of gasoline". I get so tired of "expert opinions" from people who don't really know what they are talking about, I decided to do the little experiment thing to set the record straight. Old guys like me have a pretty good knowledge of what works and what doesn't work. The problem arises when a lot of young people new to the hobby follow my posts and see a statement like that from a "senior member" and take it as truth.

I'm bored this morning, and since the Devil finds work for idle hands (as my Grandma used to say), here's a video of the two cycle engine running my lighting plant.

[ame]https://www.youtube.com/watch?v=Cn8reNH8mBM&feature=youtu.be[/ame]

[ame]https://www.youtube.com/watch?v=Cn8reNH8mBM&feature=youtu.be[/ame]

Today I moved the adjustable ignition point lever in the opposite direction to where it had been set, reversed my electric drill, and started the engine running in the opposite direction. It runs as good , possibly even better when turning counter-clockwise. All previous runs have been with the engine turning clockwise, although it doesn't look like that in the videos. My water-pump only works in one direction, so I had to cross the o-ring belt drive to achieve this.

Similar threads

- Replies

- 6

- Views

- 2K

- Replies

- 14

- Views

- 5K