You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

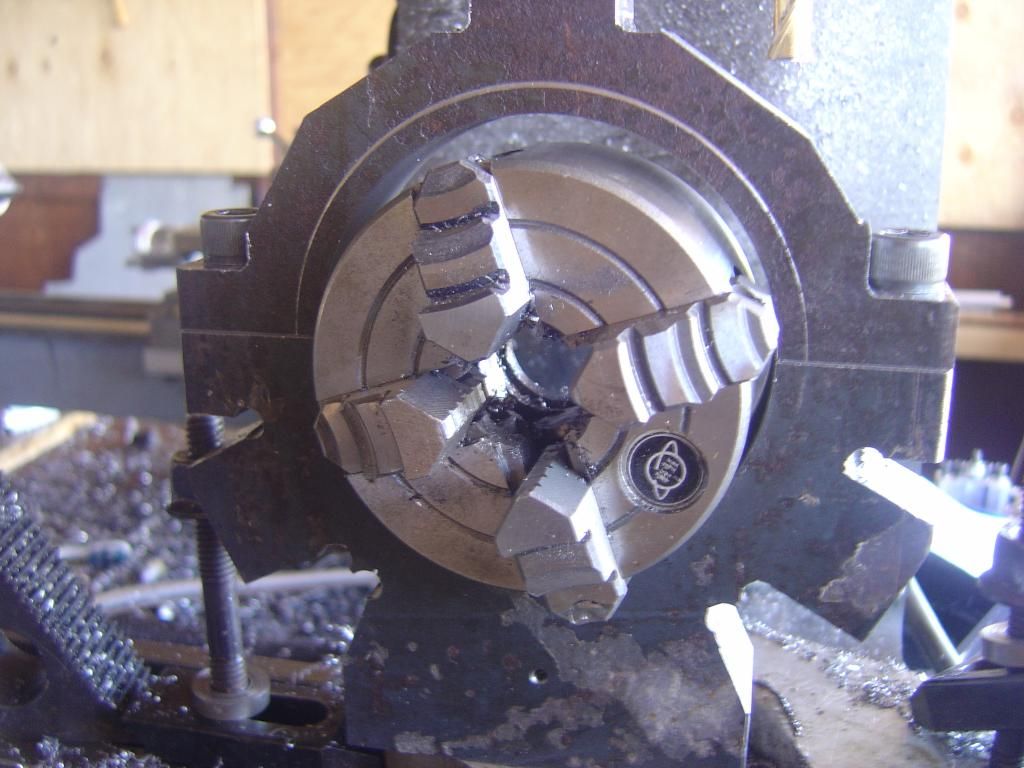

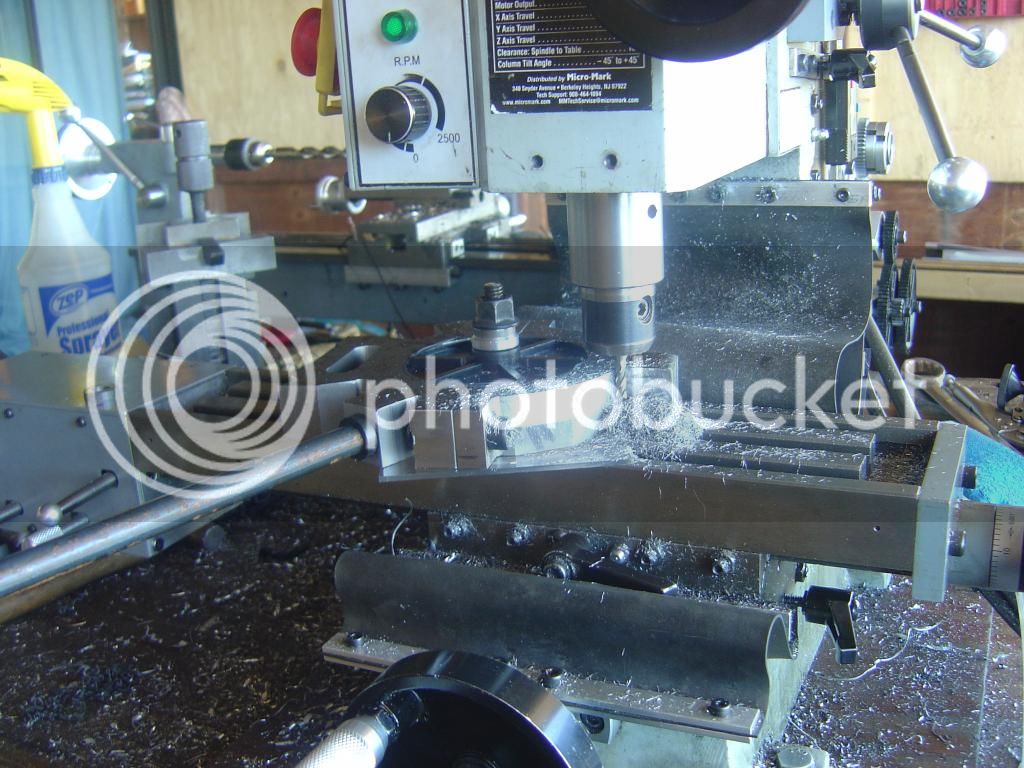

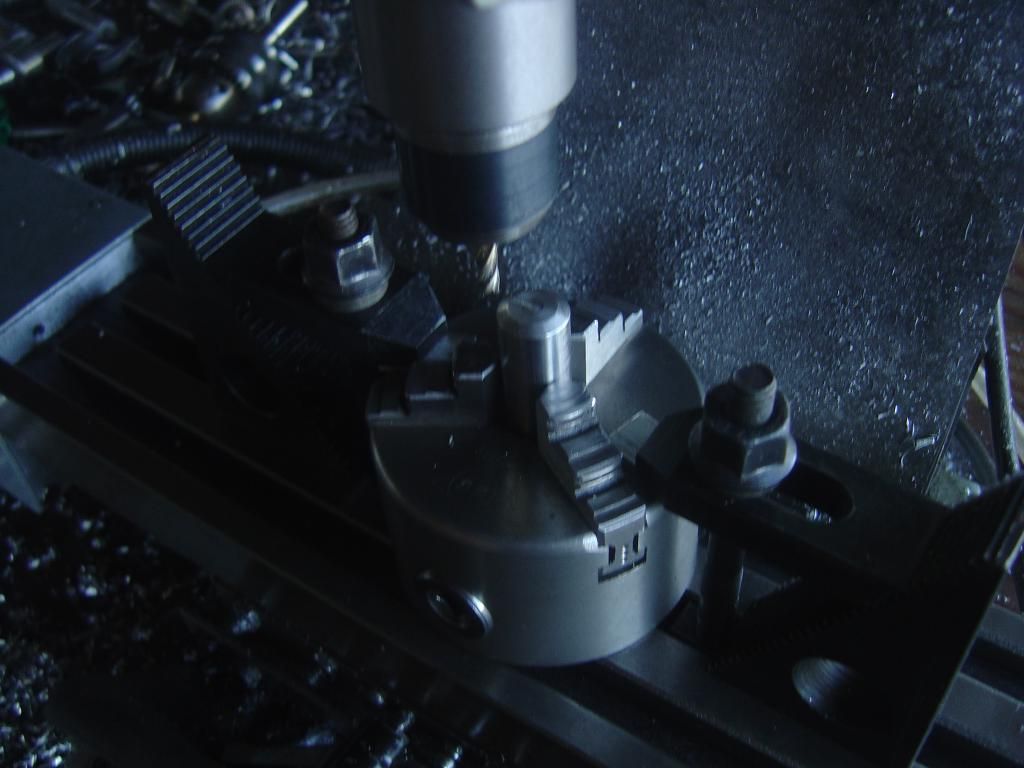

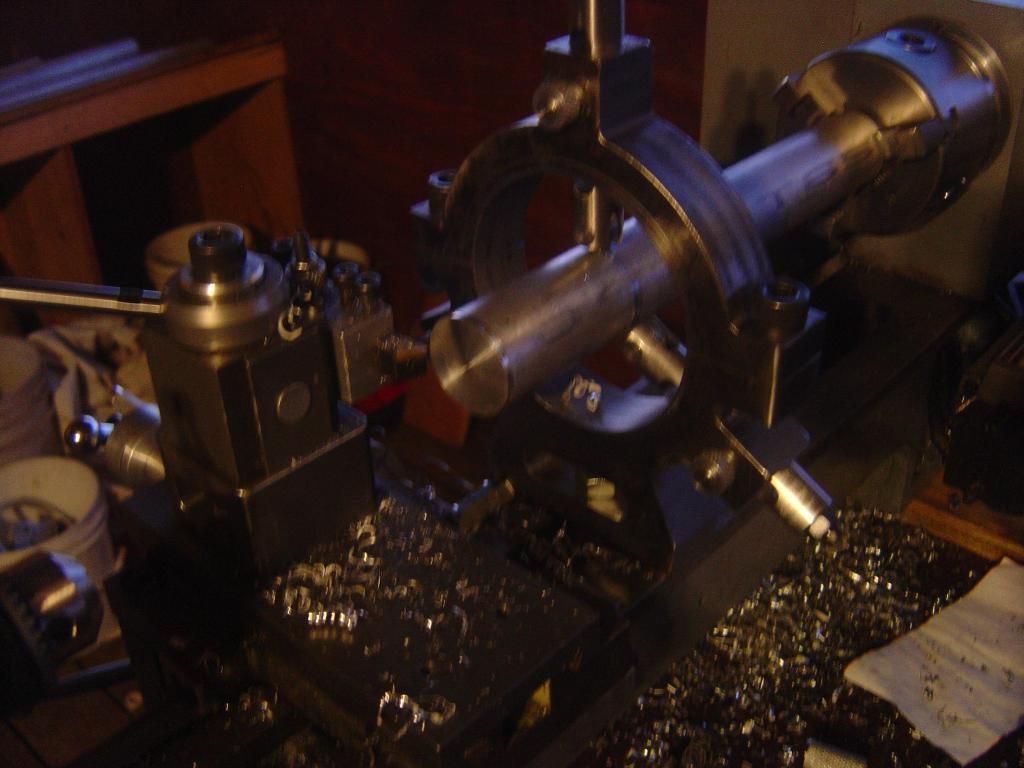

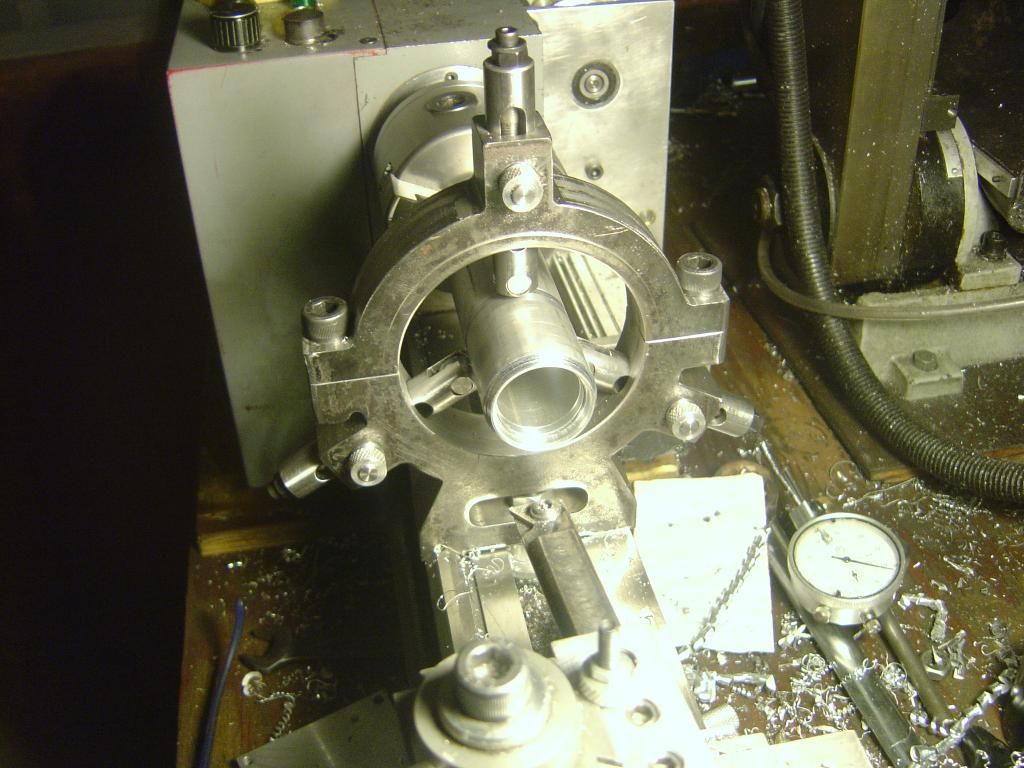

3" steady rest for 7x12 lathe

- Thread starter MCRIPPPer

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Swifty

Well-Known Member

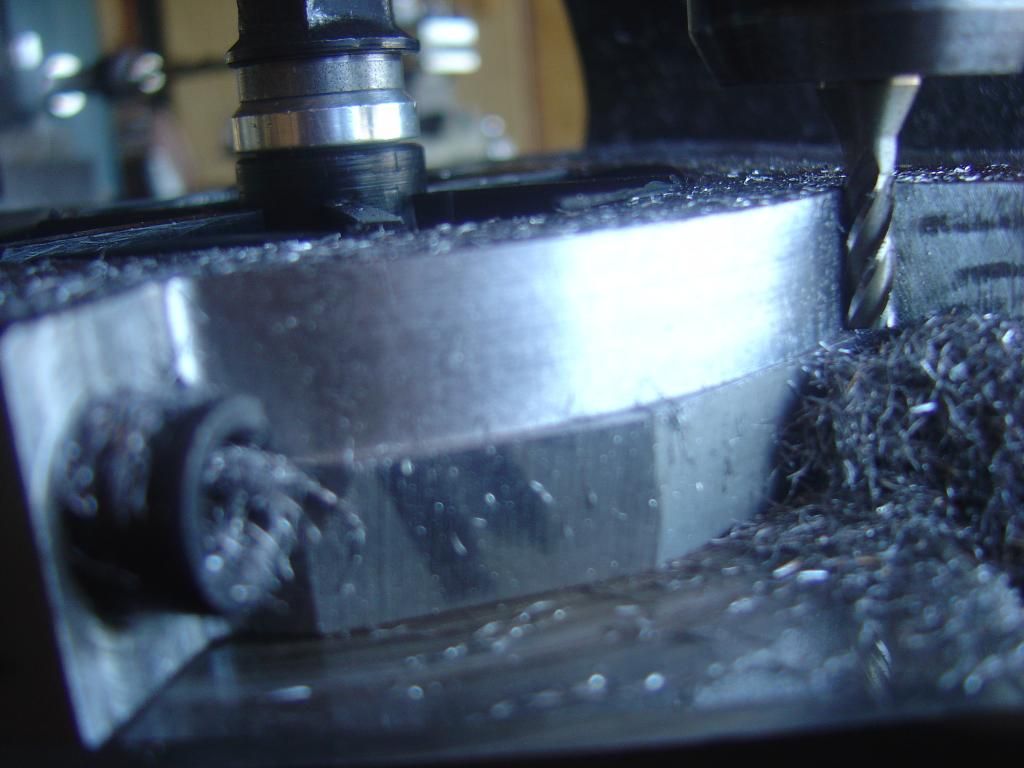

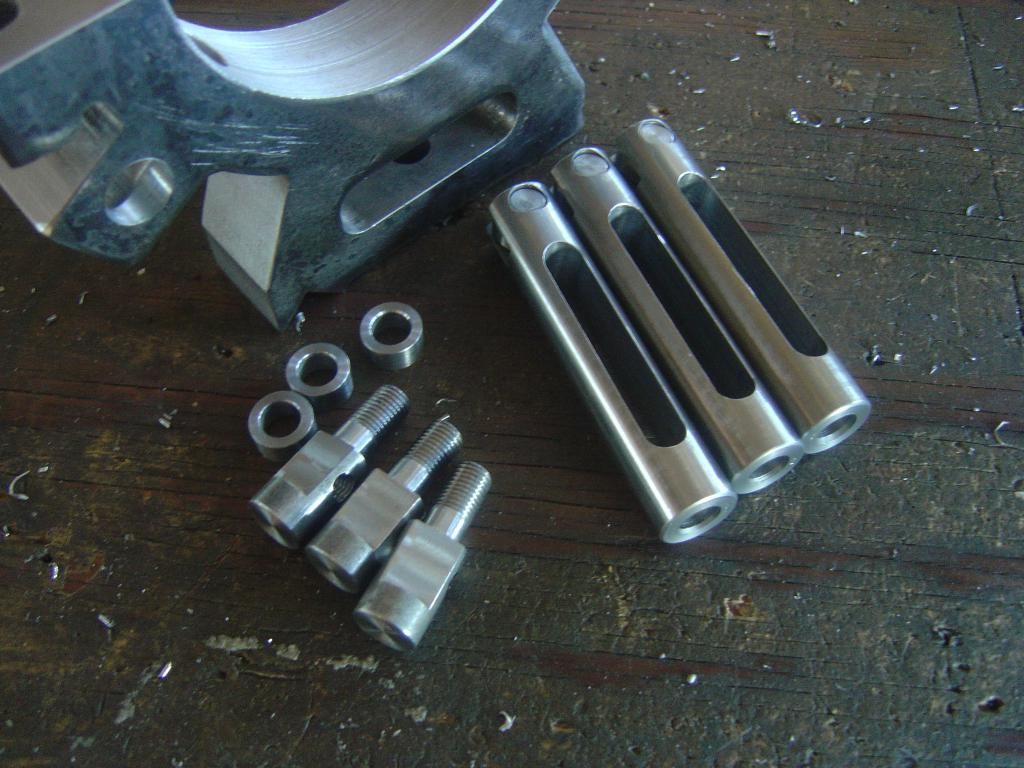

You certainly had to remove a lot of material. I like the way you milled the outside radius.

Paul.

Paul.

chucketn

Senior Citizen

Very nice work, MCRIPPer. I have made patterns in wood for a steady and follower rest, intending to cast them in Aluminum. They are definitly not as nice as yours. If you have CAD abilities it would be a great service to your fellow Mini lathe owners if you draw up your creation and share it.

- Joined

- May 27, 2010

- Messages

- 2,999

- Reaction score

- 1,171

Very well made to last forever. A fixed steady is so useful when you have jobs that a not too long and not short.

DIY my own too but I took short cut with left-overs.

DIY my own too but I took short cut with left-overs.

You certainly had to remove a lot of material. I like the way you milled the outside radius.

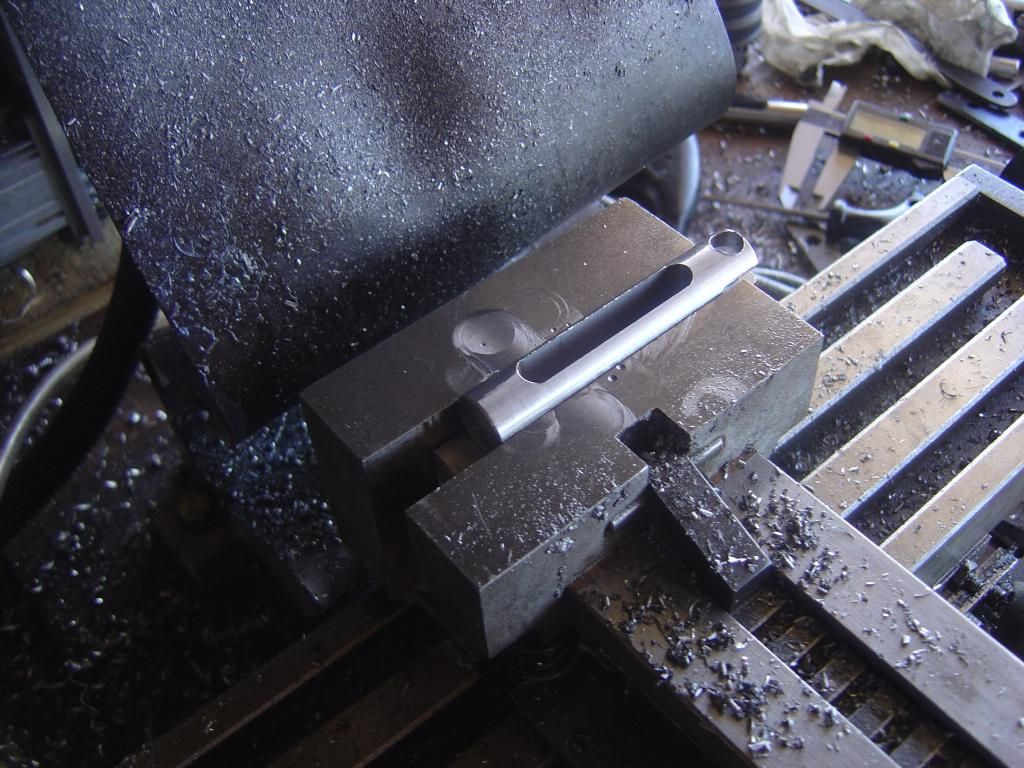

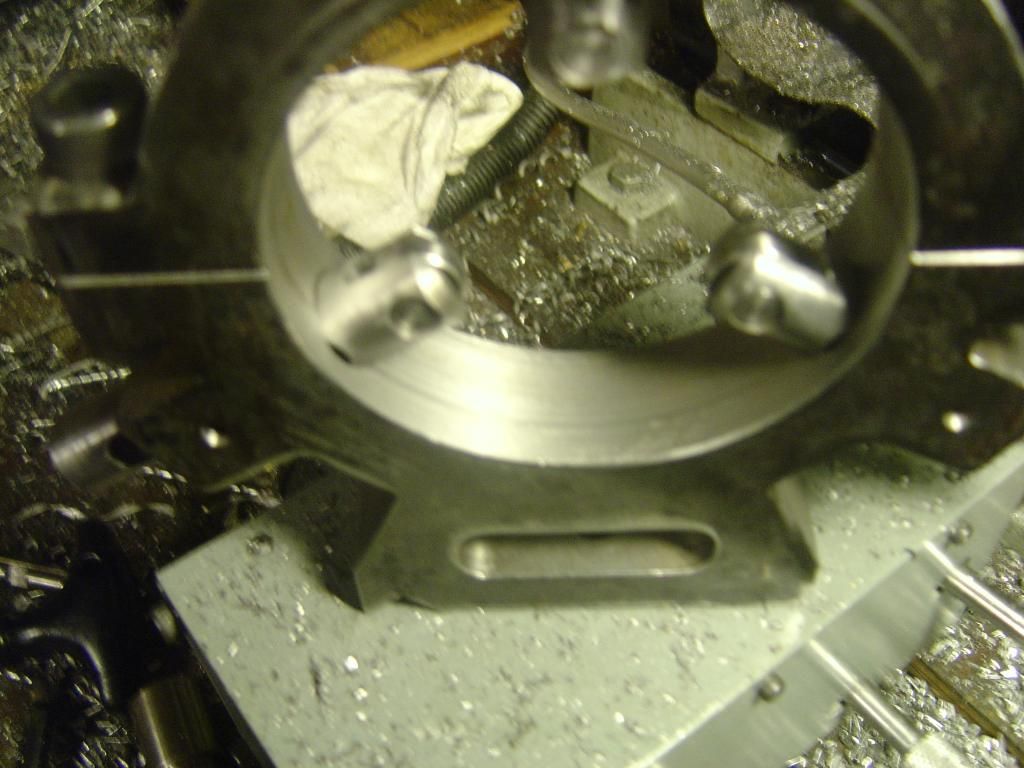

since i dont have a rotary table(havn't made one yet), i decided to use a plastic wheel from my harbor freight bandsaw stand. just turned the od about 10-20 thousandths bigger than the id of the steady and bored the center in the same setup for a pivot. worked well and no real chatter from the small end mill.

Paul.

Very nice work, MCRIPPer. I have made patterns in wood for a steady and follower rest, intending to cast them in Aluminum. They are definitly not as nice as yours. If you have CAD abilities it would be a great service to your fellow Mini lathe owners if you draw up your creation and share it.

i have freecad and google sketchup. how do i post cad to the internet? i can draw it up now that its almost done

are there any other good free cad things out there that are better?

i wonder how much it would cost to get one lazer cut?

Very well made to last forever. A fixed steady is so useful when you have jobs that a not too long and not short.

DIY my own too but I took short cut with left-overs.

nice steady rest. it looks like its got a few bucks worth of brass on it!

chucketn

Senior Citizen

MCRIPPer, at the bottom of the reply box, there is a button labled 'Manage Attachments'. Click that and navagate to where you saved the file. The rest is like attaching a file to an e-mail.

Chuck

Chuck

Tin Falcon

Well-Known Member

- Joined

- Jul 9, 2007

- Messages

- 7,207

- Reaction score

- 787

You should be able to export you freecad file as a pdf then upload as an

attachment or a upload to the download section.

Tin

attachment or a upload to the download section.

Tin

- Joined

- May 27, 2010

- Messages

- 2,999

- Reaction score

- 1,171

This is one World Best ''Steady Rest'' money cannot buy.

But I am too lazy to upgrade mine made out of scrap bin and surplus. But when a critical job comes up,I would have to make one

very good looking and robust Steady.

But I am too lazy to upgrade mine made out of scrap bin and surplus. But when a critical job comes up,I would have to make one

very good looking and robust Steady.

- Joined

- May 27, 2010

- Messages

- 2,999

- Reaction score

- 1,171

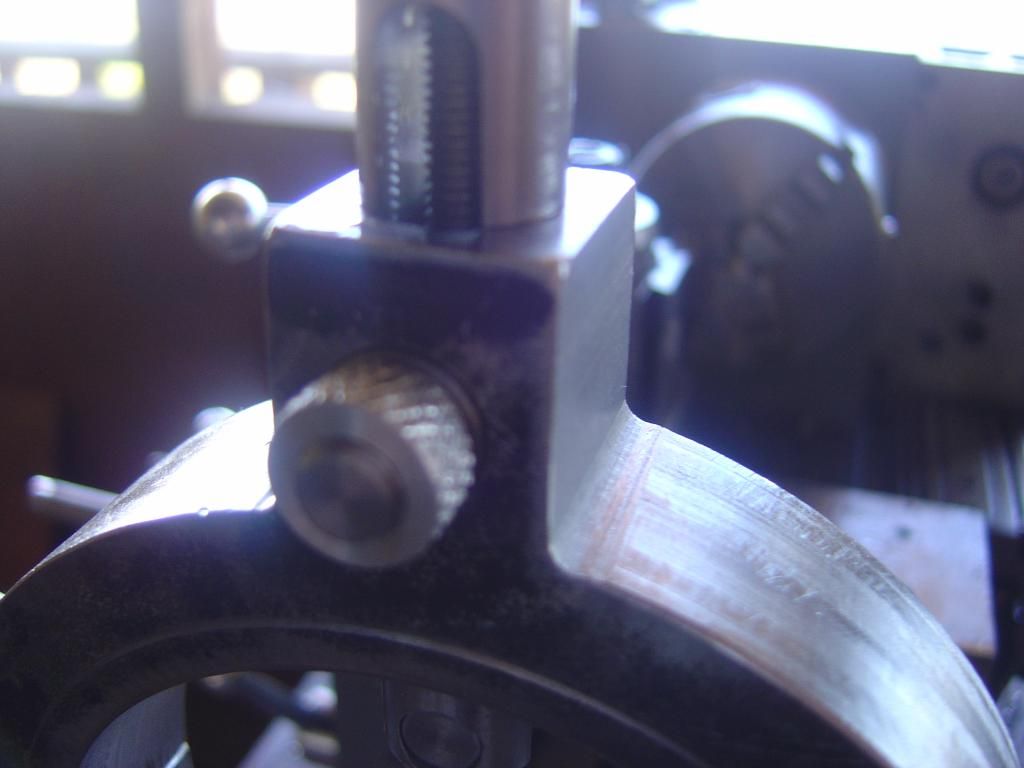

W/o a steady rest when turning a long bar stock on a mini lathe,the job will fly out and usually with the last cut.

Gus was turning the American PopCorn Steam Engine Frame and was forced to come up with a steady rest in two days.

The Over-hung was a wee bitty to much.Facing and OD reduction very risky.

Will find time to finish up the steady rest with support rollers. Meanwhile I had to put lotsa grease to support job.The frame was a surplus from PopCorn Engine for the spoked flywheel.

Gus was turning the American PopCorn Steam Engine Frame and was forced to come up with a steady rest in two days.

The Over-hung was a wee bitty to much.Facing and OD reduction very risky.

Will find time to finish up the steady rest with support rollers. Meanwhile I had to put lotsa grease to support job.The frame was a surplus from PopCorn Engine for the spoked flywheel.

Last edited:

Similar threads

- Replies

- 3

- Views

- 1K

- Replies

- 14

- Views

- 910