- Joined

- Apr 3, 2011

- Messages

- 192

- Reaction score

- 305

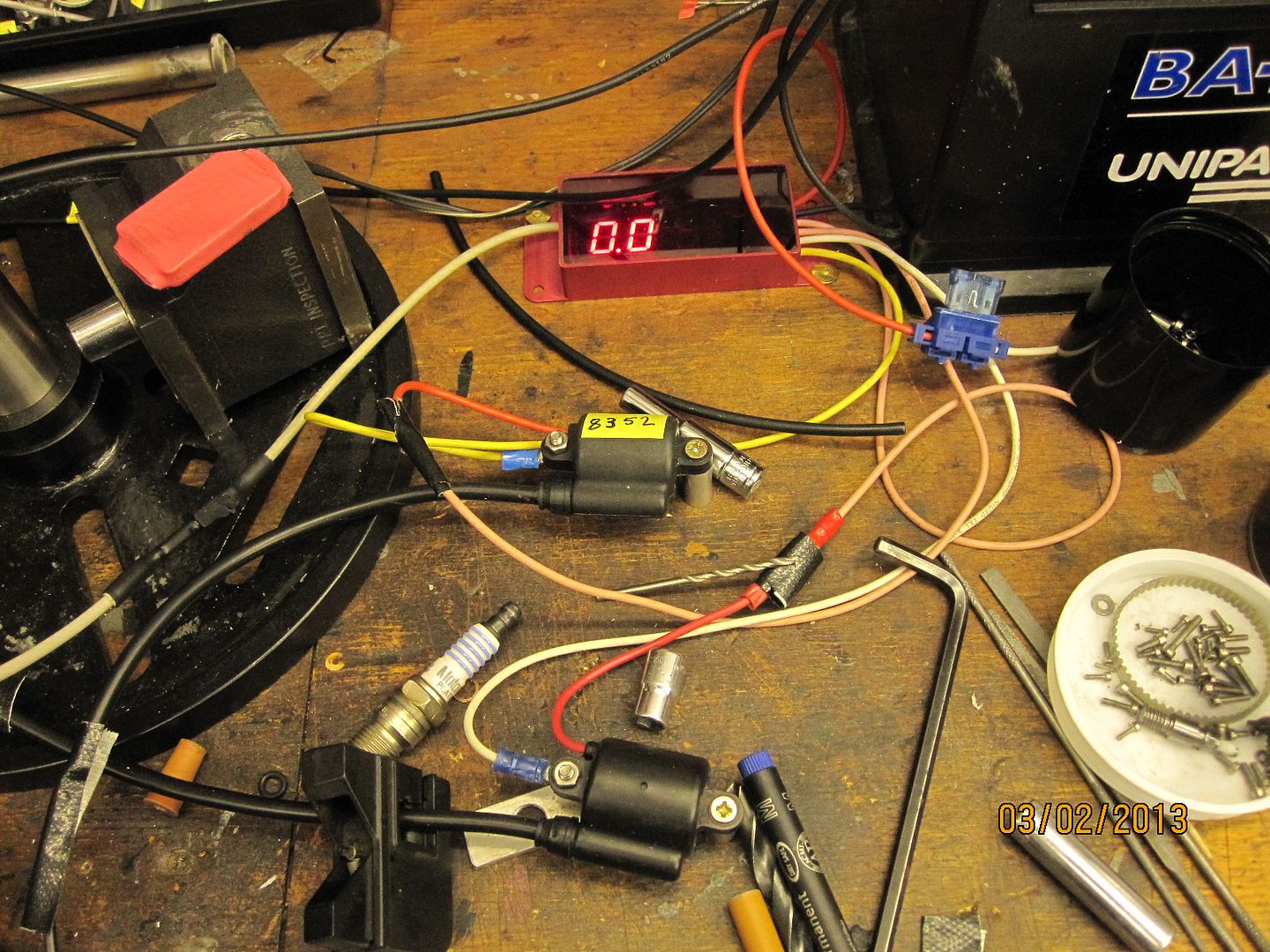

George, thanks for your drawing. I'm going to re-design my plug and see if I can get some sort of bush soldered to the end. High temp adhesive isn't going to work very well in ptfe I suspect.

You are more organised than me looking at your drawing!

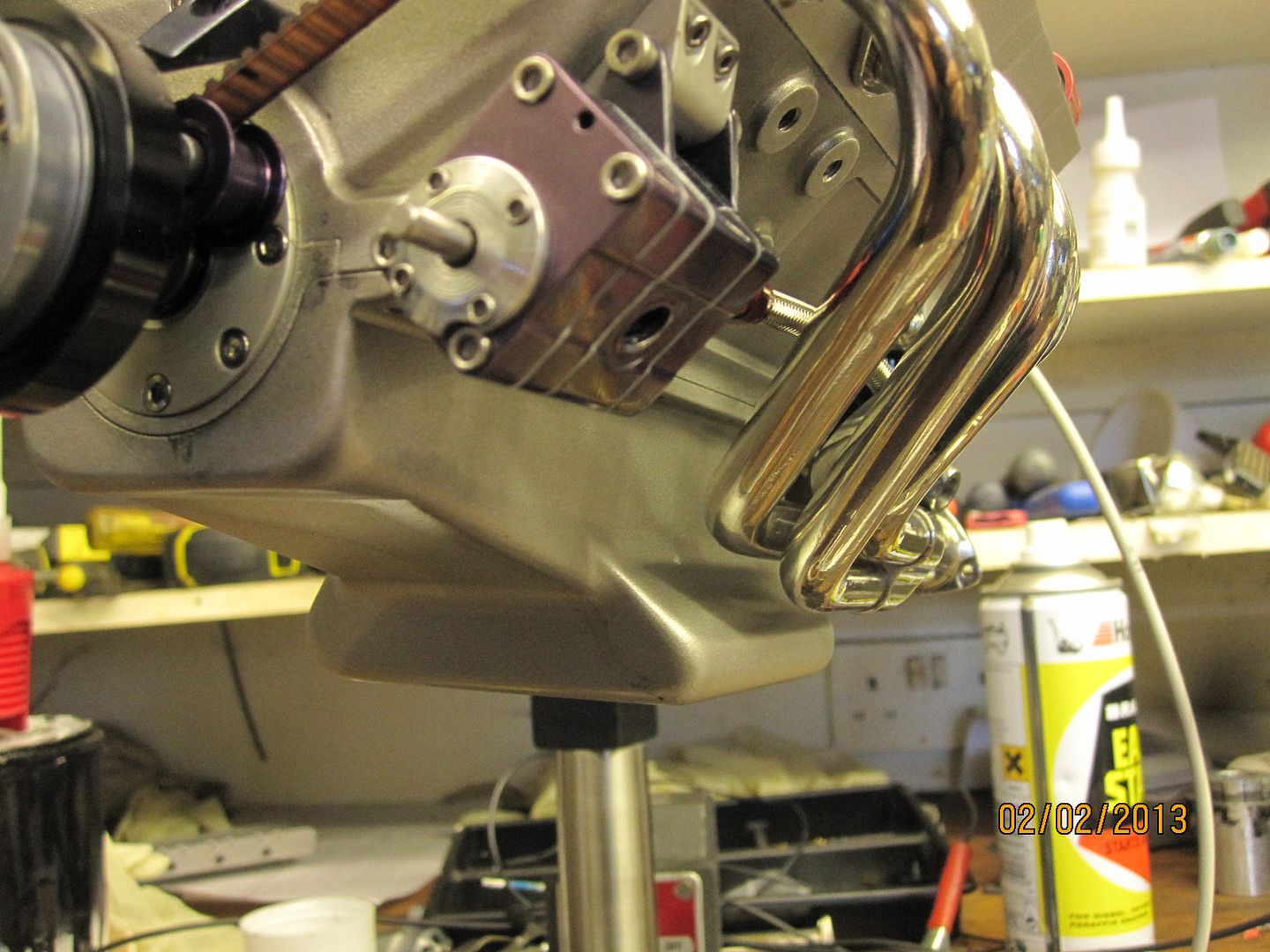

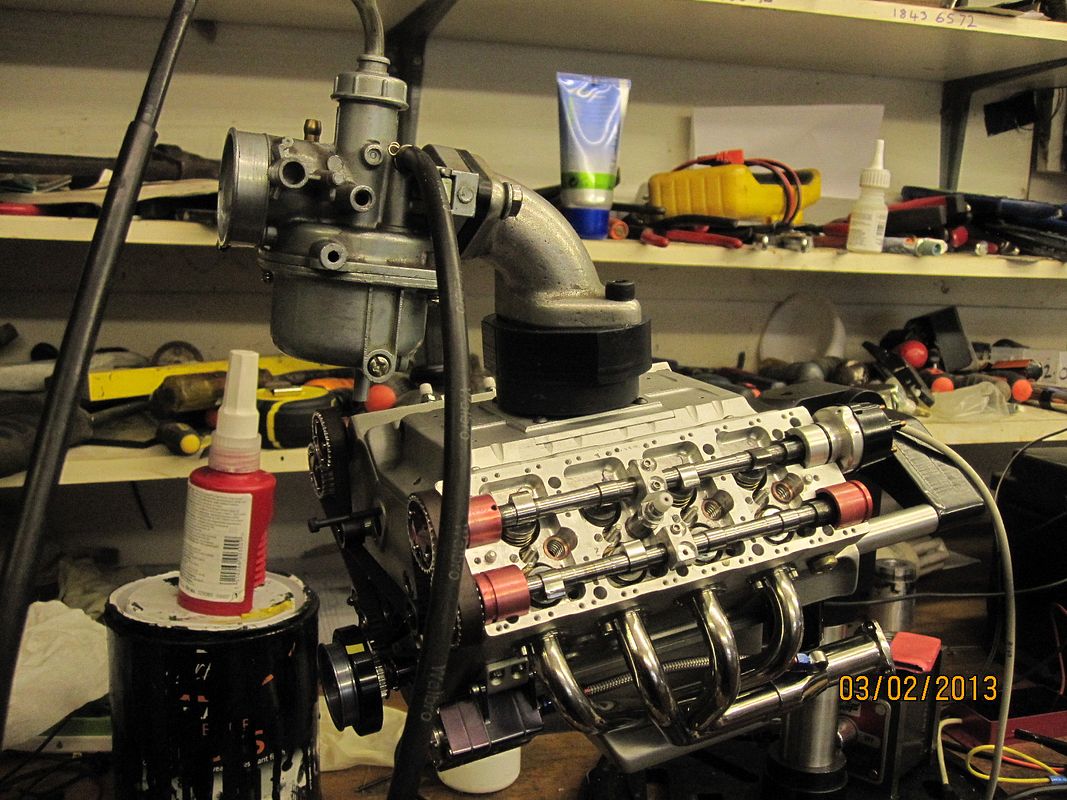

Ian, the valve heads are 8mm dia, and the stem big dia is 1/4".

I happened to have the springs already, but they originally came from Entex Springs in Nottingham, UK. Whereabouts are you?

I would be wary of giving you the exact spec at the moment as I have no idea if they will be strong enough for the job.

Valves take 1.3kg (2.9lbs) to just start to open. I suspect the valves are going to bounce at high rpm but I'd rather start off

too soft than too hard.

Cheers.

You are more organised than me looking at your drawing!

Ian, the valve heads are 8mm dia, and the stem big dia is 1/4".

I happened to have the springs already, but they originally came from Entex Springs in Nottingham, UK. Whereabouts are you?

I would be wary of giving you the exact spec at the moment as I have no idea if they will be strong enough for the job.

Valves take 1.3kg (2.9lbs) to just start to open. I suspect the valves are going to bounce at high rpm but I'd rather start off

too soft than too hard.

Cheers.