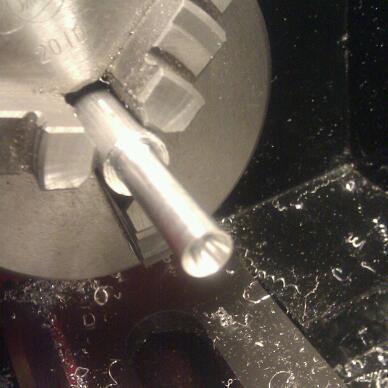

I didn't take any in progress shots for the next few turning steps, but I flipped it back around in the chuck, turned the front of the shaft down to just over 4mm and the rest to just over 6mm. I then machined the 15 degree angle transition, which was rather tricky as the electronics box for the lathe gets in the way of the top slide. I had to juggle everything around a fair bit to find a setting that would let me machine the whole taper. Next I faced the underside of the head of the bolt (err, I mean, the crankweb

) and added the little step called for in the plans. After that I very slowly eased the 6mm part down until it would be a press fitting into the bearing, then I polished it with emery cloth so it would rotate fairly smoothly.

Then came the reason for the delay since my last post - threading the shaft M4. I chamfered the end of the shaft by 45 degrees but I just wasn't able to get the die started. Figuring it was due to the cheap tap & die set I have (I'm replacing them piece by piece with higher quality items as they break) I ordered a higher quality die and waited for that to arrive. No joy. Scratching my head, I checked the shaft diameter - I had left it at 4.1mm! Silly me... I chucked it again and took it down to about 3.96mm or so and a small shoulder to help starting and then went ahead and cut the thread. No problems this time.

That brings us up to date with my efforts this evening:

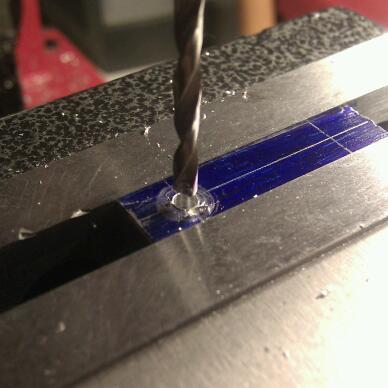

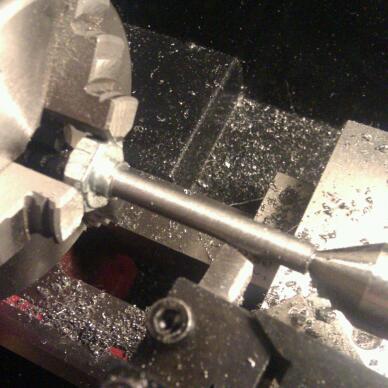

As I have a 4-jaw chuck and I'm only building one of these (so far) I chose not to make the offset collet to turn the crank pin. Instead I marked out the location for the crank pin centre by first very carefully setting my lathe tool to centre height, and using the cross slide to mark it straight across the centre:

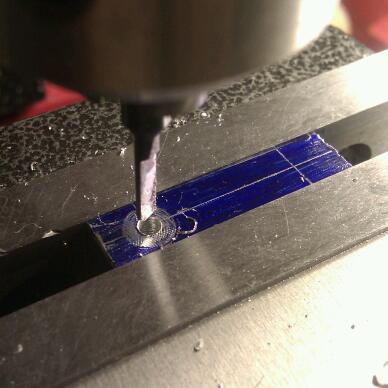

Then I set it to be as close to dead centre as I could manage, calculated how many ticks to wind the cross slide back to achieve a 5mm offset, and wound it on back. I rotated the chuck by hand to score the 5mm radius:

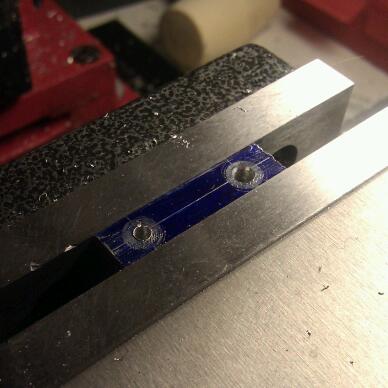

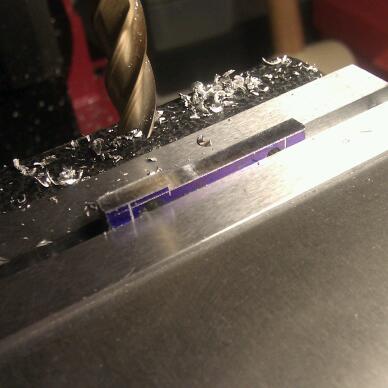

I made up a little aluminium collet to hold the shaft for the offset turning operation as the chuck couldn't grip such a small radius at such a large offset. I spent some time making sure the marked location was well centred, then I spotted a little centre there just in case I needed to re-set it later:

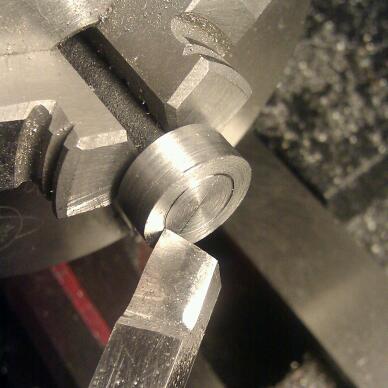

I took my time with the offset turning and as a result the piece did not slip and I did not need to use the centre. I took off tiny amounts with each pass at the end, taking off about 0.0005" at a time until the conrod fit nicely. Here's the resultant crank pin:

And the fit - the conrod is slightly thicker than 3mm for now, hence it is slightly proud of the crank pin:

Just to see how successful my homemade reamer had been, I measured the crank pin - bang on 2.99mm. It seems like the reamer did a fine job!

Here is where I'm at overall:

I'm not sure which part to tackle next - I'm feeling a bit nervous about machining the cast iron for the piston!

- but it was an easy process. First I heated them to cherry red, quenched in water, then polished the flat face and tempered to a dark straw by heating the base and watching the colours creep towards the tip. It goes VERY fast with tools this small. Result (apologies for the lack of focus, I couldn't get my camera to reliably focus):

- but it was an easy process. First I heated them to cherry red, quenched in water, then polished the flat face and tempered to a dark straw by heating the base and watching the colours creep towards the tip. It goes VERY fast with tools this small. Result (apologies for the lack of focus, I couldn't get my camera to reliably focus):